Organic fertilizer raw material treatment system

A processing system and raw material technology, applied in the field of organic fertilizer raw material processing systems, can solve problems such as low processing efficiency, and achieve the effect of avoiding bending and reducing length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below by means of specific embodiments:

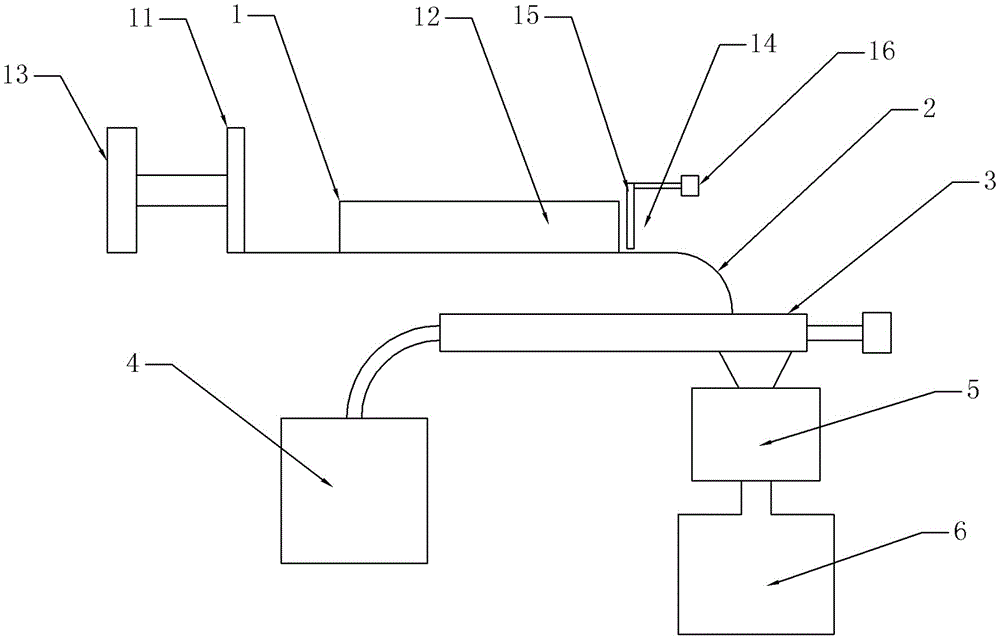

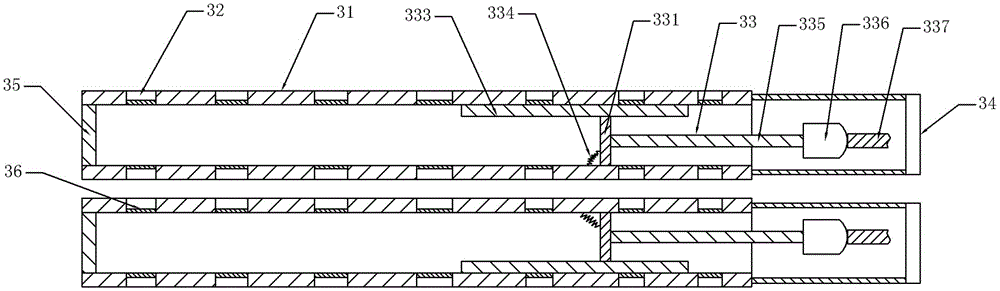

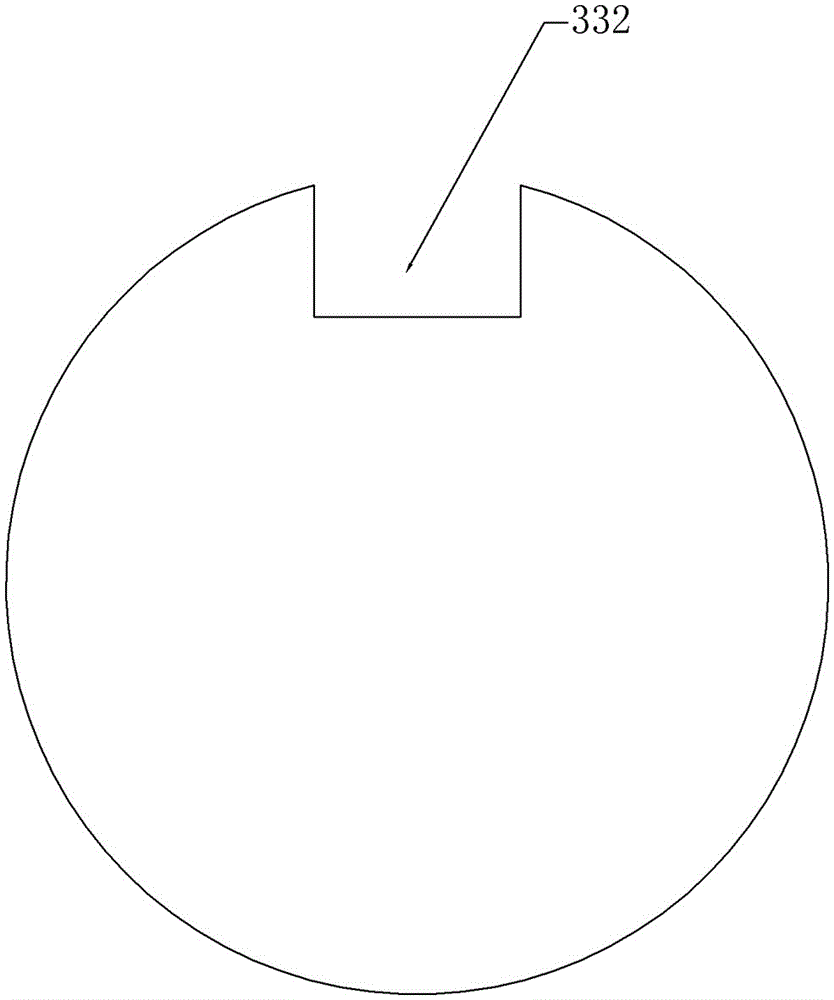

[0029] The reference signs in the drawings of the description include: cutting mechanism 1, push plate 11, guide cylinder 12, hydraulic press 13, discharge port 14, rotary cutter 15, first rotating motor 16, conveyor belt 2, rolling mechanism 3, press Roller 31, first through hole 32, juice transfer mechanism 33, piston plate 331, groove 332, projection 333, return spring 334, support rod 335, cylindrical cam 336, limit rod 337, second rotating motor 34, the first A pressure valve 35, a second pressure valve 36, a filter 4, a filter box 41, a liquid inlet 42, a support plate 43, a leak hole 44, a clay honeycomb brick layer 45, gauze 46, a liquid outlet pipe 47, a pulverizer 5, Drying device 6, floating ball 60, shell 61, liner 62, support column 621, scraper 622, cavity 63, powder inlet 64, powder outlet 65, water inlet 66, water outlet 67, spiral tube 68, protrusion 681 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com