Preparation method and application of octyl methoxycinnamate

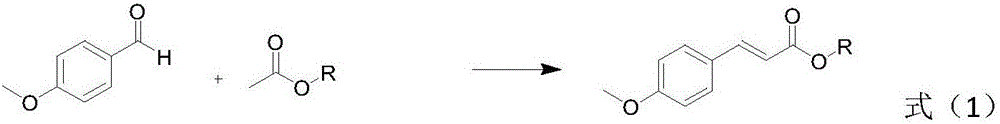

A technology for methoxymeat and p-methoxybenzaldehyde is applied in the field of preparation of p-methoxycinnamate, can solve problems such as high cost and regeneration, and achieves high use efficiency, simple operation process and good catalytic effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of embodiment 1 methyl methoxycinnamate

[0032] 1. Stir 136 grams (1mol) of p-methoxybenzaldehyde, 148 grams (2mol) of methyl acetate, 303 grams (3mol) of dipropylamine and 1000g toluene, and control the temperature at 0°C;

[0033] 2. Add 285 g (1.5 mol) of titanium tetrachloride catalyst dropwise for about 30 minutes. After the dropwise addition, raise the temperature to 20°C and react for 5 hours;

[0034] 3. After the reaction was completed, the reaction solution was washed with 5% dilute hydrochloric acid until neutral, washed with water, and the organic phase was dried by adding anhydrous sodium sulfate. After desolventization, 188 grams of methyl p-methoxycinnamate were obtained, with a yield of 98%.

[0035] Synthetic route is as shown in formula (2):

[0036]

Embodiment 2

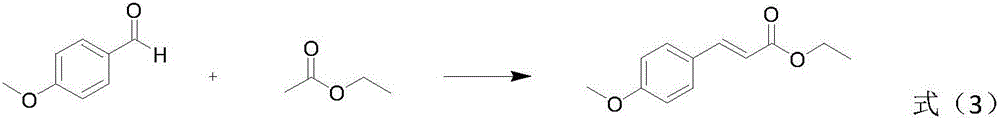

[0037] The preparation of embodiment 2 ethyl methoxycinnamate

[0038] 1. Stir 136 g (1 mol) of p-methoxybenzaldehyde, 132 g (1.5 mol) of ethyl acetate, 170 g (2 mol) of piperidine and 1000 g of n-hexane, and control the temperature at -5°C;

[0039] 2. Add 95 g (0.5 mol) of titanium tetrachloride catalyst dropwise for about 15 minutes. After the dropwise addition, raise the temperature to 30°C and react for 2 hours;

[0040] 3. After the reaction was completed, the reaction solution was washed with 5% dilute hydrochloric acid to neutrality, washed with water, the organic phase was dried by adding anhydrous sodium sulfate, and 203 grams of ethyl p-methoxycinnamate was obtained after desolventization, with a yield of 99%.

[0041] Synthetic route is as shown in formula (3):

[0042]

Embodiment 3

[0043] The preparation of embodiment 3 p-methoxycinnamic acid isobutyl esters

[0044] 1. Stir 136 g (1 mol) of p-methoxybenzaldehyde, 140 g (1.2 mol) of isobutyl acetate, 158 g (2 mol) of pyridine and 1500 g of xylene, and control the temperature at -10°C;

[0045] 2. Add 152 g (0.8 mol) of titanium tetrachloride catalyst dropwise for about 20 minutes. After the dropwise addition, raise the temperature to 10°C and react for 12 hours;

[0046] 3. After the reaction was completed, the reaction solution was washed with 5% dilute hydrochloric acid to neutrality, washed with water, and the organic phase was dried by adding anhydrous sodium sulfate. After desolventization, 230 g of isobutyl p-methoxycinnamate was obtained, with a yield of 98%.

[0047] Synthetic route is as shown in formula (4):

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com