Preparation method and application for composite film of copper, zinc, tin, sulphur and three-dimensional graphene

A technology of graphene film and copper zinc tin sulfur, which is applied in the field of nanomaterials, can solve the problems that the composite film cannot reach the quantum dot level and the preparation process is complicated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Step 1. Prepare a three-dimensional graphene film on a conductive substrate:

[0024] First, graphene oxide was prepared based on the ultrasonically improved Hummer method, which was reduced in a muffle furnace at a high temperature of 200-1000 °C. The mixture of redox graphene powder and ethanol solution was ball milled. The mass ratio of cobalt oxide ball milling beads to redox graphene powder is about 10000:1 to 2000:1, the speed is 200-400 rpm, and the ball milling time is 10-30h. Finally, the ball-milled graphene dispersion solution is suction-filtered and dried to obtain single-layer graphene powder.

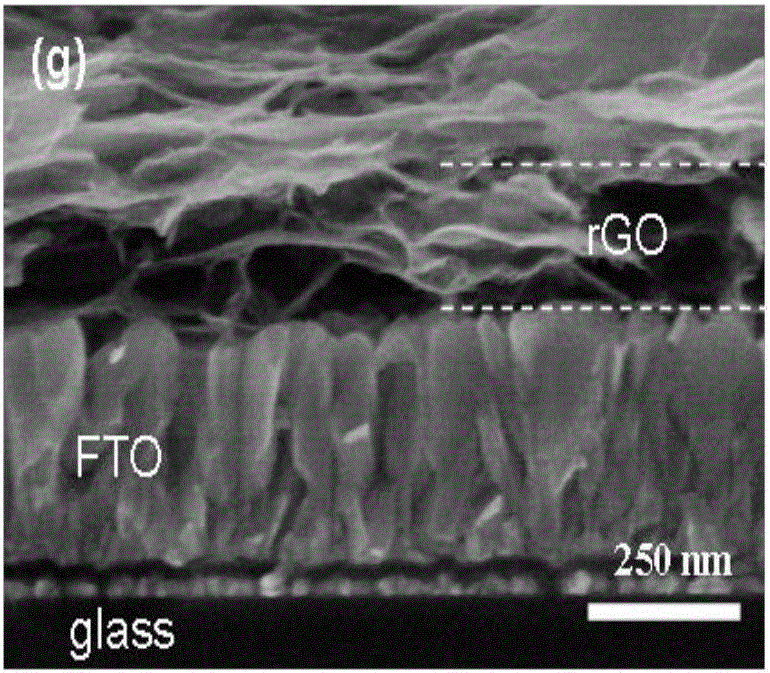

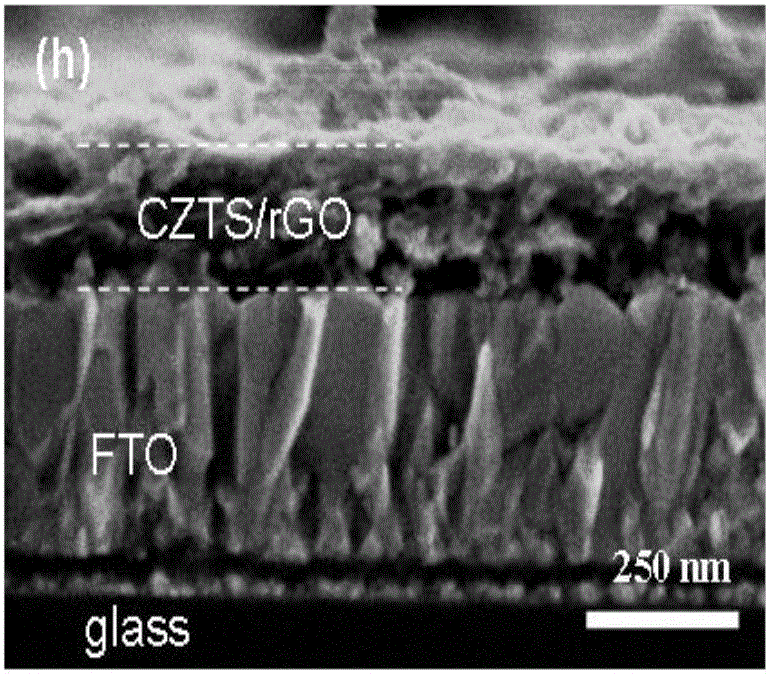

[0025] Secondly, the single-layer graphene powder after ball milling is added into an organic solvent to prepare a graphene slurry, which is printed on the conductive surface of the FTO conductive glass by screen printing.

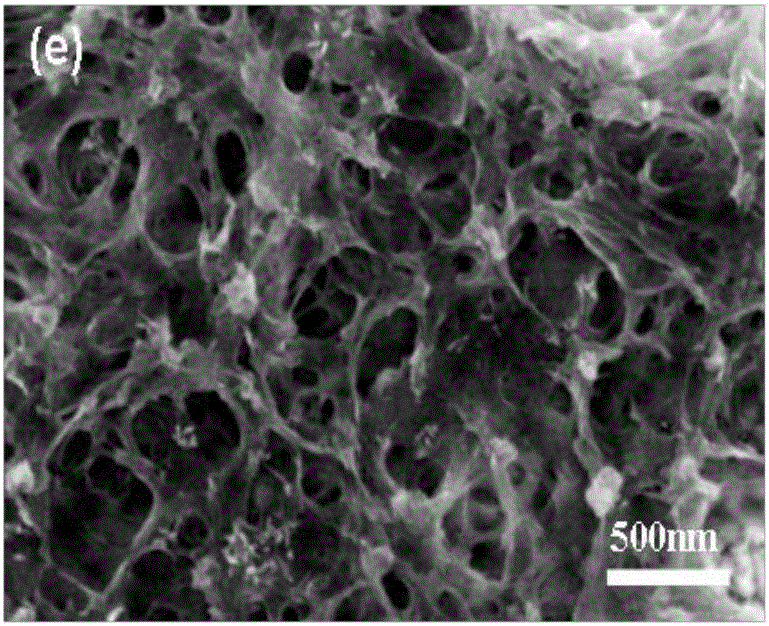

[0026] Finally, the above samples were placed in a blast drying oven for heat treatment to obtain a three-dimensional porous graphene film ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com