Carbon quantum dot loaded cuprous thiocyanate photovoltaic film and preparation method thereof

A technology of cuprous thiocyanate and carbon quantum dots, applied in circuits, electrical components, final product manufacturing, etc., can solve the problem of rare modification of CuSCN thin films, and achieve favorable structural modulation and potential applications, good optoelectronics Features, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

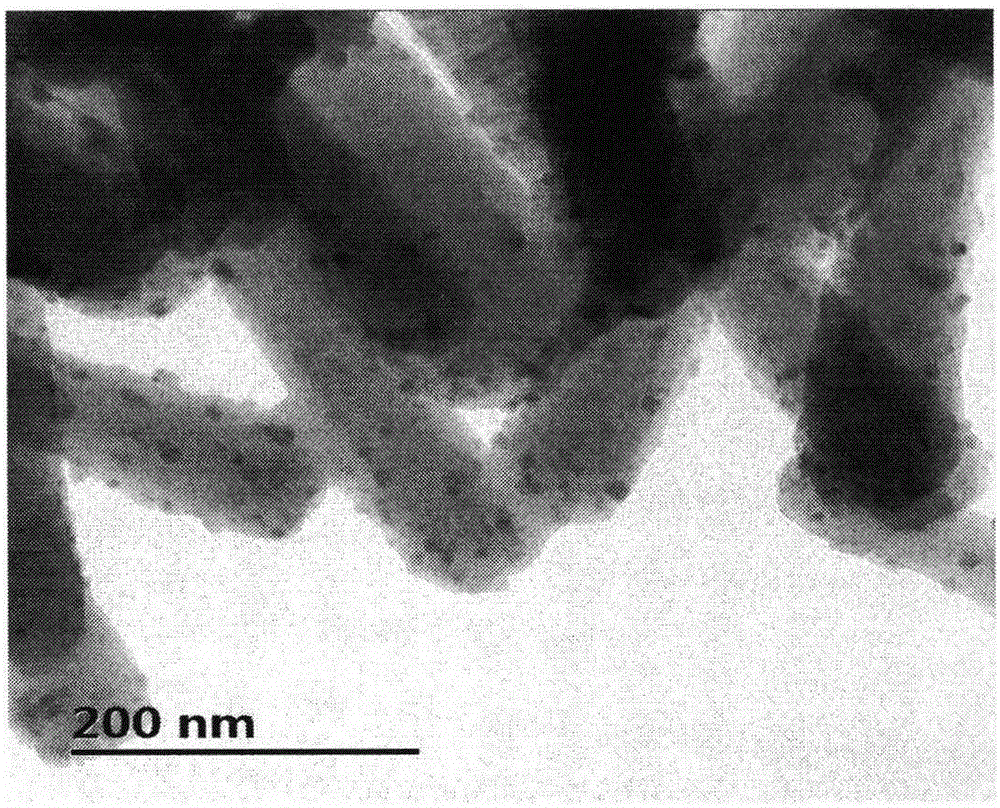

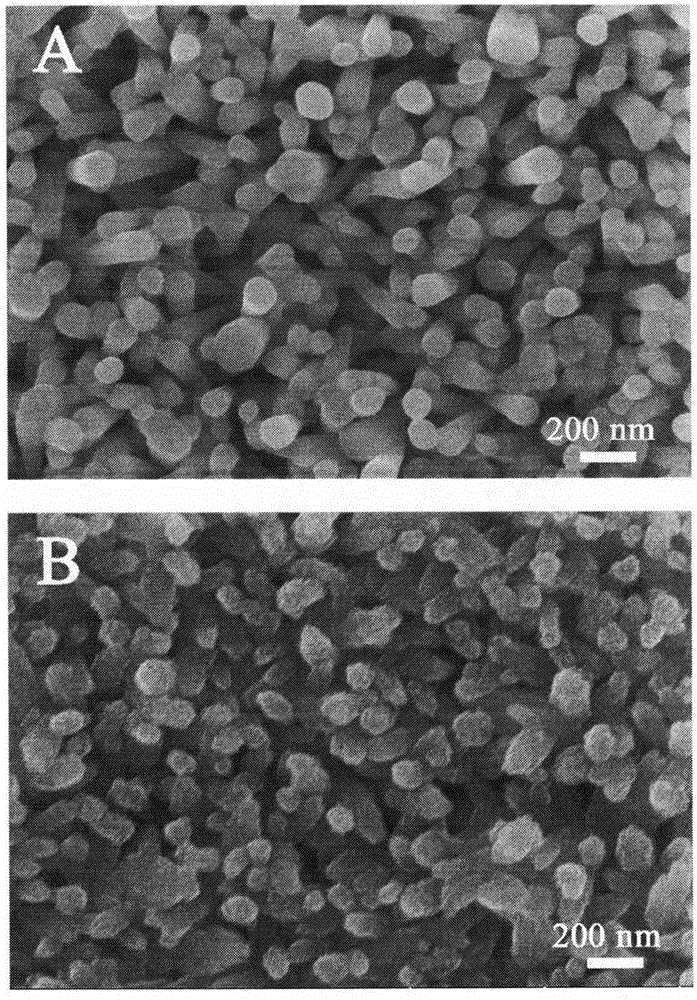

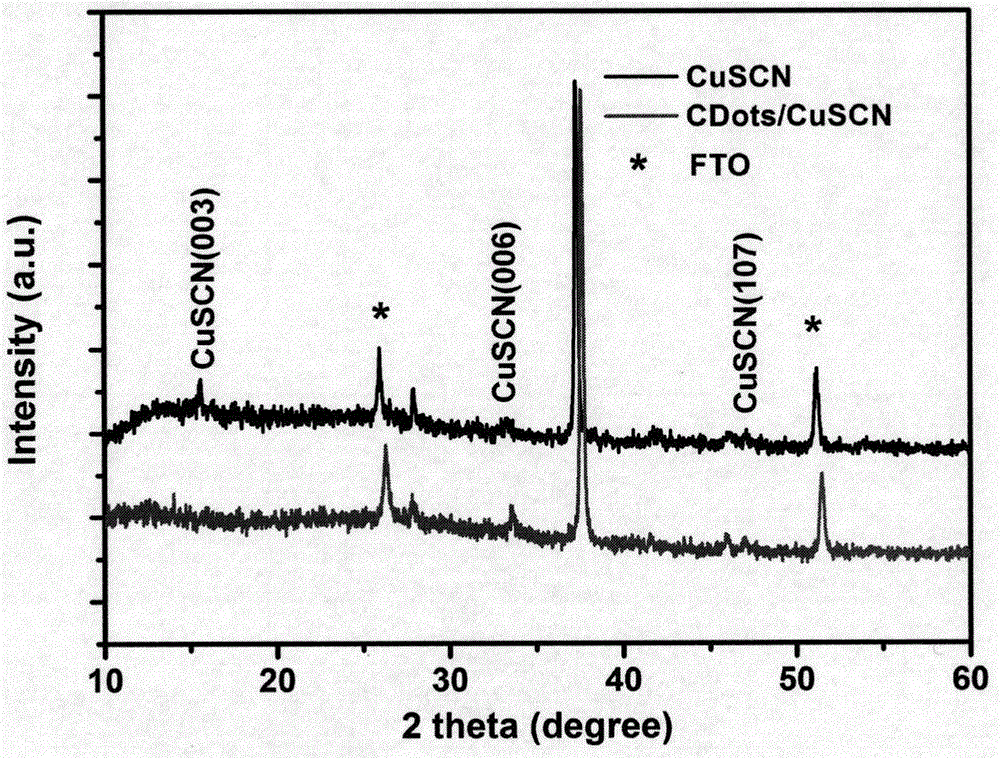

[0020] Dissolve 1.50g of anhydrous citric acid in 80mL of deionized water, stir with a magnetic stirrer for 10 minutes, transfer to a hydrothermal reaction kettle for hydrothermal reaction at 220°C for 24 hours, obtain a colorless and transparent solution after natural cooling, filter and centrifuge , to prepare a well-dispersed aqueous solution of carbon quantum dots; weigh 0.09g copper sulfate pentahydrate (CuSO 4 ·5H 2 (2), 0.105g ethylenediaminetetraacetic acid (EDTA) and 0.026g potassium thiocyanate (KSCN) powder are respectively dissolved in the carbon quantum dot aqueous solution that the above-mentioned preparation obtains, after mixing and stirring, make CuSO in the solution 4 The molar concentration of KSCN and EDTA is 12mmol / L, the molar concentration of KSCN is 3mmol / L, the three substances CuSO 4 : EDTA: The molar ratio of KSCN is 1: 1: 0.25, and the gained solution is used as the electrolyte of electrochemical deposition process; In the electrochemical reaction...

Embodiment 2

[0028] Dissolve 2.0g of anhydrous citric acid in 100mL of deionized water, stir with a magnetic stirrer for 10 minutes, transfer to a hydrothermal reaction kettle for hydrothermal reaction at 200°C for 20 hours, and obtain a colorless and transparent solution after natural cooling, filter and centrifuge , to prepare a well-dispersed aqueous solution of carbon quantum dots; weigh 0.09g copper sulfate pentahydrate (CuSO 4 ·5H 2 (2), 0.105g ethylenediaminetetraacetic acid (EDTA) and 0.052g potassium thiocyanate (KSCN) powder are dissolved in respectively in the carbon quantum dot aqueous solution that above-mentioned preparation obtains, after mixing and stirring, make CuSO in the solution 4 The molar concentration of KSCN and EDTA is 12mmol / L, the molar concentration of KSCN is 6mmol / L, the three substances CuSO 4 : EDTA: The molar ratio of KSCN is 1: 1: 0.5, and the gained solution is used as the electrolyte of electrochemical deposition process; In the three-electrode system...

Embodiment 3

[0031] Dissolve 1.8g of anhydrous citric acid in 80mL of deionized water, stir with a magnetic stirrer for 10 minutes, transfer to a hydrothermal reaction kettle for hydrothermal reaction at 200°C for 24 hours, obtain a colorless and transparent solution after natural cooling, filter and centrifuge , to prepare a well-dispersed aqueous solution of carbon quantum dots; weigh 0.09g copper sulfate pentahydrate (CuSO 4 ·5H 2 (2), 0.105g ethylenediaminetetraacetic acid (EDTA) and 0.104g potassium thiocyanate (KSCN) powder are respectively dissolved in the carbon quantum dot aqueous solution that above-mentioned preparation obtains, after mixing and stirring, make CuSO in the solution 4 The molar concentrations of , EDTA and KSCN are all 12mmol / L, and the three substances CuSO 4 : EDTA: The molar ratio of KSCN is 1: 1: 1, and the gained solution is used as the electrolyte of electrochemical deposition process; In the electrochemical reaction tank of the three-electrode system of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com