Method for preparing high thermal conductivity graphite film by using graphene-doped polyamic acid resin

A technology of polyamic acid resin and high thermal conductivity graphite, which is applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc. It can solve the problems of low production efficiency, poor thermal conductivity of carbonized film, and unexamined thermal conductivity of graphite film, etc. , to achieve the effect of reducing production cost and production cycle, significant economic and social benefits, and shortening graphitization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

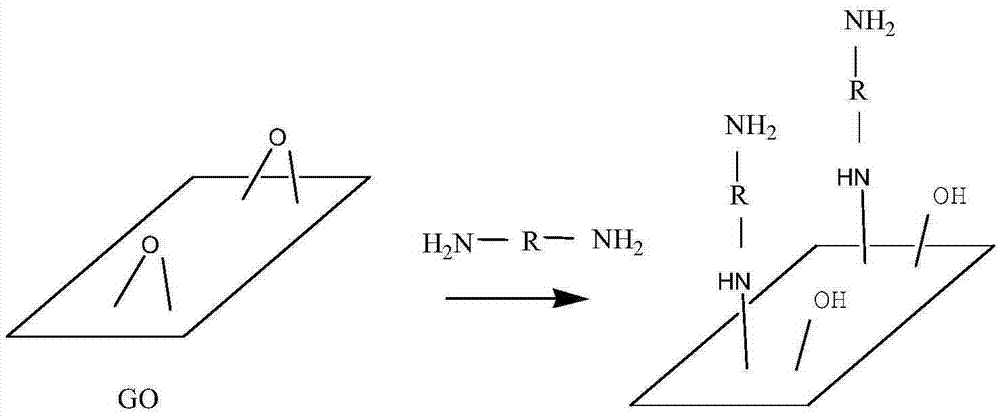

Image

Examples

Embodiment 1

[0033] A kind of method utilizing graphene-doped polyamic acid resin of the present invention to prepare high thermal conductivity graphite film may further comprise the steps:

[0034] (1) Graphene (graphene is graphene oxide or graphene oxide obtained by the Humers method) is added to the strong polar organic solvent DMAc, ultrasonically dispersed for 60min, and the concentration obtained is prepared as a 0.1wt% graphene dispersion;

[0035] (2) Diamine ODA and dianhydride PMDA are added respectively in the graphene dispersion liquid that step (1) makes in equimolar ratio and carry out stirring reaction, and specific operation mode is: first diamine ODA monomer is once added to In the graphene dispersion, after being fully dissolved, the dianhydride PMDA monomer is added in batches as the stirring reaction proceeds, and the reaction is stirred for 6 hours in an ice-water bath and under the protection of an inert gas to obtain an in-situ polymerization with a solute concentrat...

Embodiment 2

[0040] A kind of method utilizing graphene-doped polyamic acid resin of the present invention to prepare high thermal conductivity graphite film may further comprise the steps:

[0041] (1) Graphene (graphene is graphene oxide or graphene oxide obtained by the Humers method) is added in the strong polar organic solvent DMF, ultrasonically dispersed for 60min, and the prepared concentration is 2wt% graphene dispersion;

[0042] (2) Diamine PDA and dianhydride BPDA are added respectively in the graphene dispersion liquid that step (1) makes in equimolar ratio and carry out stirring reaction, and specific operation method is: first diamine PDA monomer is once added to In the graphene dispersion, after being fully dissolved, the dianhydride BPDA monomer is added in batches along with the stirring reaction, and the reaction is stirred for 6 hours in an ice-water bath and under the protection of an inert gas to obtain an in-situ polymerization with a solute concentration of 20wt%. G...

Embodiment 3

[0047] A kind of method utilizing graphene-doped polyamic acid resin of the present invention to prepare high thermal conductivity graphite film may further comprise the steps:

[0048] (1) Graphene (graphene is graphene oxide or graphene oxide obtained by the Humers method) is added in the strong polar organic solvent DMF, ultrasonically dispersed for 60min, and the prepared concentration is 5wt% graphene dispersion;

[0049] (2) Diamine PDA, ODA and dianhydride ODPA, BPDA are respectively added to the graphene dispersion prepared in step (1) in an equimolar ratio to carry out stirring reaction. The specific operation method is: first equimolar diamine Add PDA and ODA monomers to the graphene dispersion at one time. After fully dissolving, add equimolar dianhydride ODPA and BPDA monomers in batches as the stirring reaction proceeds. Under the protection of ice-water bath and inert gas, Stirring and reacting for 6h to obtain an in-situ polymerized graphene-doped polyamic acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com