Activated carbon having hollow form

A technology of activated carbon and morphology, applied in inorganic chemistry, non-metallic elements, carbon compounds, etc., can solve the problems of high bed pressure, low reaction efficiency, incomplete regeneration, etc., to reduce operating resistance, increase reaction area, and performance recovery. thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The raw materials used in this embodiment include 70% anthracite, 28% coal tar, 2% diluent and 10% water by mass percentage, and the preparation method includes the following steps:

[0031] (1) Preparation of pulverized coal: firstly crush the anthracite and then grind it into 200 mesh pulverized coal;

[0032] (2) Preparation of coal tar: add polyvinyl alcohol solution to coal tar, and then stir with coal tar evenly at 80°C to complete the dilution;

[0033] (3) Preparation of coal gypsum: add pulverized coal, coal tar and water that have been diluted into a kneader to knead to make coal gypsum evenly;

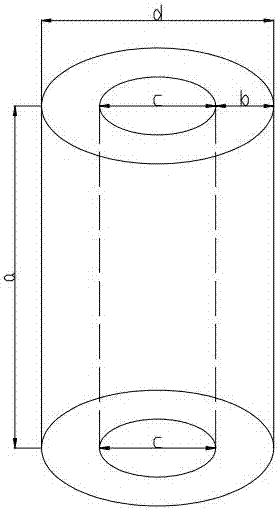

[0034] (4) Forming of activated carbon: The prepared coal paste is pressed into cylindrical hollow particles in a 11Mpa hydraulic molding machine; the particle height a is 10mm, the hollow structure diameter c is 2mm, the outer cylinder diameter d is 8mm, and the wall thickness b is 3mm;

[0035] ⑸Drying: After drying the compressed coal plaster particles at room te...

Embodiment 2

[0040] The raw materials used in this embodiment include 60% anthracite, 31% coal tar, 1% polyethylene glycol solution and 8% water by mass percentage, and the preparation method includes the following steps:

[0041] ⑴ Coal powder preparation: first crush the anthracite and then grind it into 300 mesh coal powder;

[0042] ⑵Coal tar preparation: Add the diluent to the coal tar, and then stir it evenly with the coal tar at 90°C to complete the dilution;

[0043] (2) Preparation of coal paste: Add coal powder, diluted coal tar and water into a kneader and knead evenly to make coal paste;

[0044] (4) Molding of activated carbon: Press the prepared coal paste into columnar hollow particles in an 8Mpa hydraulic molding machine; the particle height a is 6mm, the hollow structure diameter c is 1mm, the external cylinder diameter d is 5mm, and the wall thickness b is 2mm;

[0045] (5) Drying: After drying the compressed coal paste particles at room temperature, dry them at 120°C for...

Embodiment 3

[0050] The raw material that present embodiment adopts comprises the water of 65% anthracite, 30% coal tar, 2% sodium cellulose sulfonate and 3% by mass percentage, and preparation method comprises the following steps:

[0051] ⑵Preparation of coal powder: first crush the anthracite and then grind it into 400 mesh coal powder;

[0052] (2) Preparation of coal tar: add sodium cellulose sulfonate to coal tar, then stir with coal tar at 60°C to complete the dilution;

[0053] (3) Preparation of coal paste: Add coal powder, diluted coal tar and water into a kneader and knead evenly to make coal paste;

[0054] (4) Molding of activated carbon: Press the prepared coal paste into columnar hollow particles in a 12Mpa hydraulic molding machine; the particle height a is 15mm, the hollow structure diameter c is 4mm, the external cylindrical diameter d is 10mm, and the wall thickness b is 3mm;

[0055] (5) Drying: After drying the compressed coal paste particles at room temperature, dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com