Sodium alginate-silver-loaded graphene composite film with antibacterial and wound healing functions and its application

A graphene composite and sodium alginate technology, applied in bandages, absorbent pads, medical science and other directions, can solve the problems of single wound dressings, inability to take into account antibacterial and wound healing functions at the same time, etc., to promote wound healing, High potential for clinical and market applications, low cytotoxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

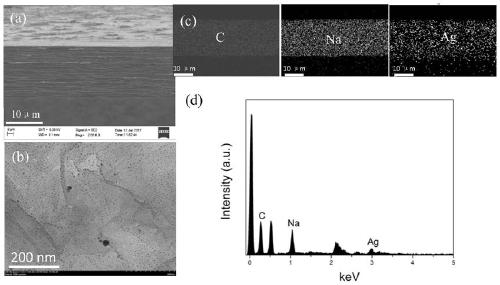

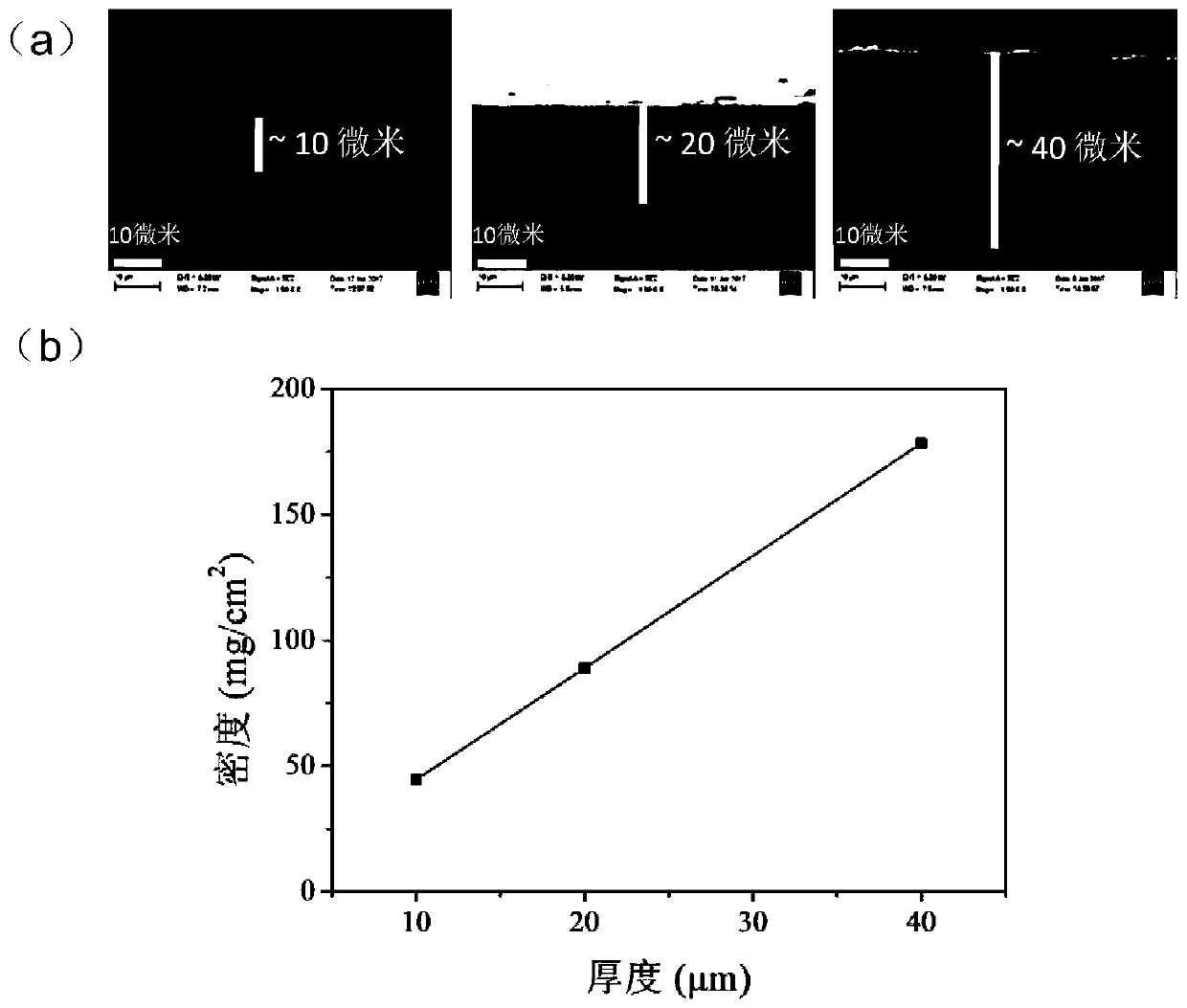

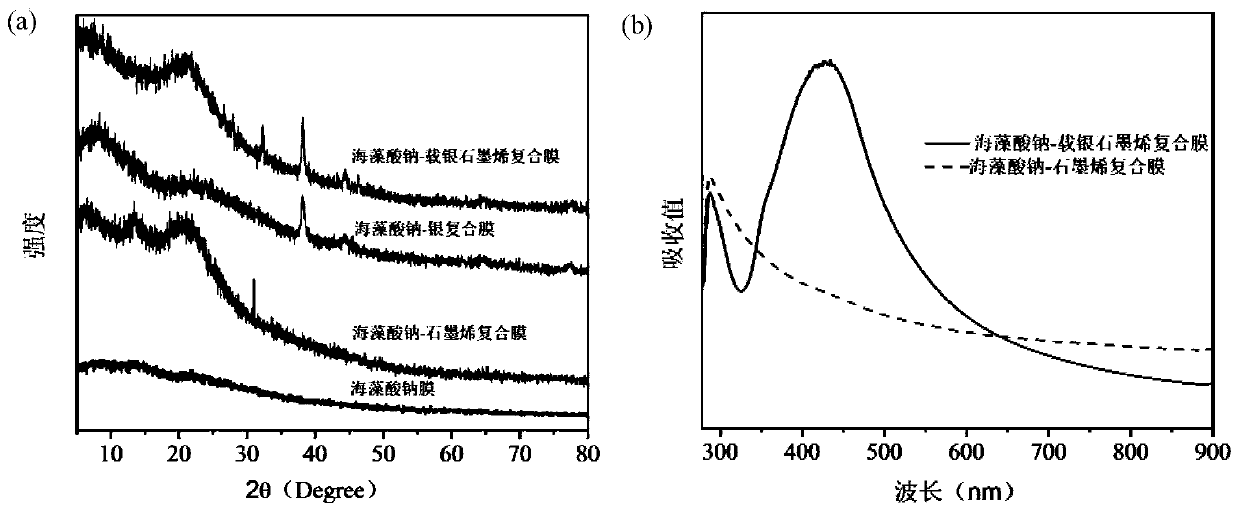

[0030] The present embodiment carries out the preparation of sodium alginate-silver-loaded graphene composite membrane according to the following steps:

[0031] a. Take 200mg of graphene oxide flakes and add them to 200mL of distilled water. After ultrasonic dispersion, add 2g of polystyrene sodium sulfate, stir to dissolve, then add 200μL of hydrazine hydrate, heat to 100°C and reflux for 24 hours. The obtained product is suction filtered, After lyophilization, the reduced graphene oxide-polystyrene sodium sulfate composite was obtained;

[0032] b. Add the reduced graphene oxide-polystyrene sodium sulfate complex obtained in step a into 50mL of water, mix well, put it into a 100mL single-necked bottle, heat to 60°C, and then add 5mL of 0.02mol The silver nitrate solution of / L is slowly added in the single-neck bottle through the double syringe pump at the speed of 0.5mL / h, after adding, continue to stir at constant temperature for 10h, centrifuge and remove the supernatant...

Embodiment 2

[0049] This embodiment prepares sodium alginate-silver-loaded graphene composite film according to the following steps:

[0050] a. Take 300mg of graphene oxide flakes and add them to 200mL of distilled water. After ultrasonic dispersion, add 2g of polystyrene sodium sulfate, stir to dissolve, then add 200μL of hydrazine hydrate, heat to 100°C and reflux for 24 hours. The obtained product is suction filtered, After lyophilization, the reduced graphene oxide-polystyrene sodium sulfate composite is obtained;

[0051] b. Add the reduced graphene oxide-polystyrene sodium sulfate complex obtained in step a into 100mL of water, mix well, put it into a 250mL single-necked bottle, heat to 60°C, and then add 10mL of / L of silver nitrate solution was slowly added to the single-necked bottle through a double syringe pump at a rate of 0.5mL / h, and continued to stir at a constant temperature for 10 hours after the addition, centrifuged and removed the supernatant to obtain a silver-loaded ...

Embodiment 3

[0056] This embodiment prepares sodium alginate-silver-loaded graphene composite film according to the following steps:

[0057] a. Take 200mg of graphene oxide flakes and add them to 300mL of distilled water. After ultrasonic dispersion, add 2g of polystyrene sodium sulfate, stir to dissolve, then add 400μL of hydrazine hydrate, heat to 100°C and reflux for 24 hours. The obtained product is suction filtered, After lyophilization, the reduced graphene oxide-polystyrene sodium sulfate composite is obtained;

[0058] b. Add the reduced graphene oxide-polystyrene sodium sulfate complex obtained in step a into 100mL of water, mix well, put it into a 250mL single-necked bottle, heat to 60°C, and then add 10mL of / L of silver nitrate solution was slowly added to the single-necked bottle through a double syringe pump at a rate of 0.5mL / h, and continued to stir at a constant temperature for 10 hours after the addition, centrifuged and removed the supernatant to obtain a silver-loaded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com