Wastewater treatment process with effect of coupling nano magnetite for enhancing activity of anaerobic microorganisms

An anaerobic microorganism and nano-magnet technology, which is applied in special compound water treatment, anaerobic digestion treatment, water/sludge/sewage treatment, etc., can solve the problems of unstable systems, poor performance of refractory pollutants, acidification, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

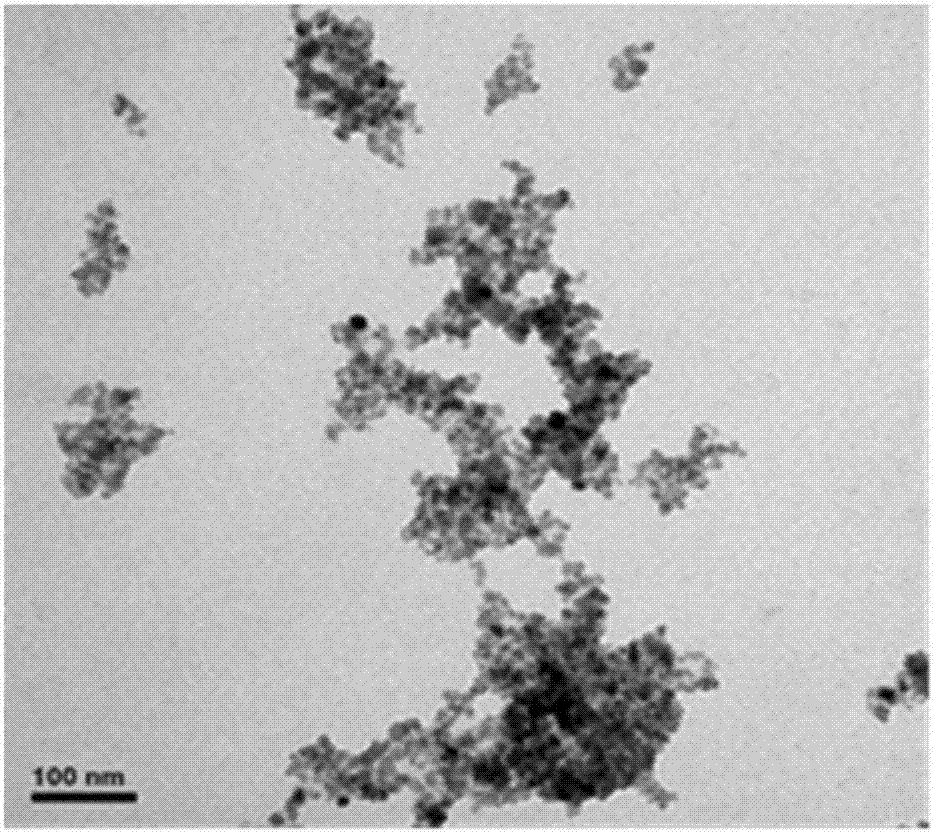

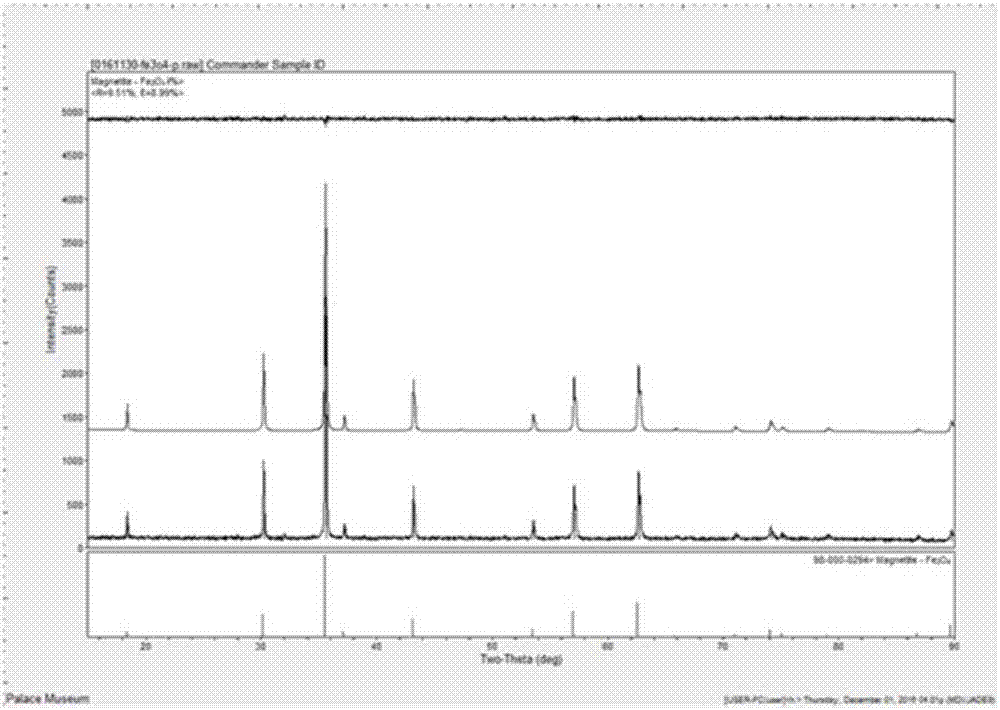

[0028] Preparation of nano-magnetite:

[0029] (1) Configure iron ion mixed solution (Fe 3+ :Fe 2+ =2:1), choose Fe 2 (SO 4 ) 3 ·xH 2 O (0.032mol) and FeSO 4 ·7H 2 O (0.032mol) was dissolved in 0.4mol / L deoxydilute sulfuric acid (400mL), and the complete dissolution of the two iron salts could be accelerated by means of a magnetic stirrer.

[0030] (2) Add excess 1.5mol / L deoxygenated sodium hydroxide solution (500mL) to the mixed solution of iron ions, and fully mix the solution with the aid of a magnetic stirrer. At this time, a black magnetite precipitate will be produced immediately (can be detected by a magnet. ).

[0031] (3) The prepared mixed solution was placed on a magnet, and after 5 minutes, the supernatant was removed by a siphon method to obtain a magnetite precipitate.

[0032] (4) Add 500ml of 0.005mol / L deoxygenated dilute sulfuric acid to the magnetite for precipitation, and mix thoroughly by magnetic stirring to neutralize the anions on the surface....

Embodiment 2

[0038] The nano-magnetite coupling process is used to treat wastewater, wherein the nano-magnetite is the nano-magnetite suspension prepared in Example 1. The specific processing method is as follows:

[0039] 1. Reaction system construction and coupling process parameters

[0040] test group:

[0041] The inoculum sludge is taken from an upflow anaerobic bioreactor that has been in operation for more than one year. The hydraulic retention time of the reactor is 1.5d, and the influent organic load is 2.0kg m -3 d -1 , the mixed liquid sludge concentration (MLSS) is about 30g L -1 . Get part of the sludge, rinse 3 times with PBS damping fluid, add the nano-magnetite suspension prepared in Example 1 (dosing is 1.55gFe / gMLVSS, is equivalent to Fe content in the wastewater of follow-up anaerobic reactor 0.5g Fe / L), the magnetite and anaerobic sludge were fully mixed evenly by magnetic stirring, and inoculated anaerobic sludge was obtained.

[0042] Using the anaerobic bottle...

Embodiment 3

[0047] The nano-magnetite coupling process is used to treat wastewater, wherein the nano-magnetite is the nano-magnetite suspension prepared in Example 1. The specific processing method is as follows:

[0048] 1. Reaction system construction and coupling process parameters

[0049] test group:

[0050] The inoculum sludge is taken from an upflow anaerobic bioreactor that has been in operation for more than one year. The hydraulic retention time of the reactor is 1.5d, and the influent organic load is 2.0kg m -3 d -1 , the mixed liquid sludge concentration (MLSS) is about 30g L -1 . Get part of the sludge, rinse 3 times with PBS damping fluid, add the nano-magnetite suspension prepared in Example 1 (dosing is 1.55gFe / gMLVSS, is equivalent to Fe content in the wastewater of follow-up anaerobic reactor 0.5g Fe / L), the magnetite and anaerobic sludge were fully mixed evenly by magnetic stirring, and inoculated anaerobic sludge was obtained.

[0051] Using the anaerobic bottle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com