Anti-fogging oligomer, coating composition and preparation method thereof

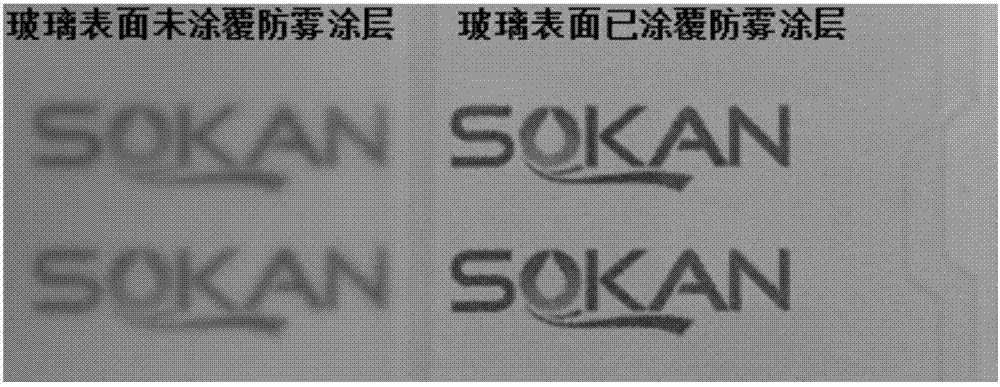

An oligomer and composition technology, applied in the direction of fire-resistant coatings, coatings, etc., can solve the problems of poor stability, poor anti-fog performance on the surface of transparent materials, and poor adhesion between anti-fog coatings and materials, and achieves the preparation of The method is simple and easy to implement, the appearance is good, and the effect of good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the above-mentioned anti-fog oligomer comprises the following steps: (1) mixing the acrylic monomer containing a hydrophilic group, the aliphatic long-chain type acrylic monomer and the first acrylic monomer, and condensing and refluxing under the protection of nitrogen react to obtain a mixed solution; (2) react the mixed solution obtained in step (1) with an acrylic monomer or oligomer containing isocyanate groups under nitrogen protection to obtain an anti-fog oligomer.

[0036] The preparation method of the above-mentioned anti-fog oligomer is simple and easy, and the yield is high, and the corresponding performance requirements can be realized or highlighted by adjusting the addition amount of each reactant.

[0037] Preferably, in step (1), the reaction temperature is 60-90°C, and the time for condensation and reflux reaction is 4-8h; in step (2), the reaction temperature is 60-90°C, and the reaction time is 1-6h.

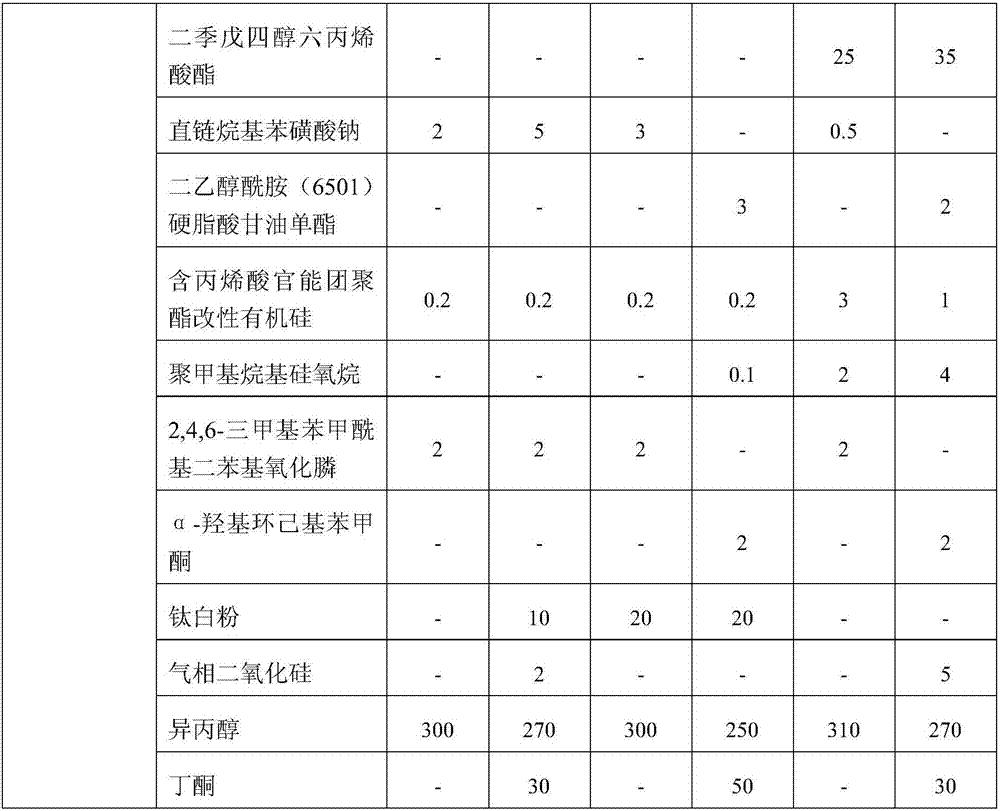

[0038] The coating com...

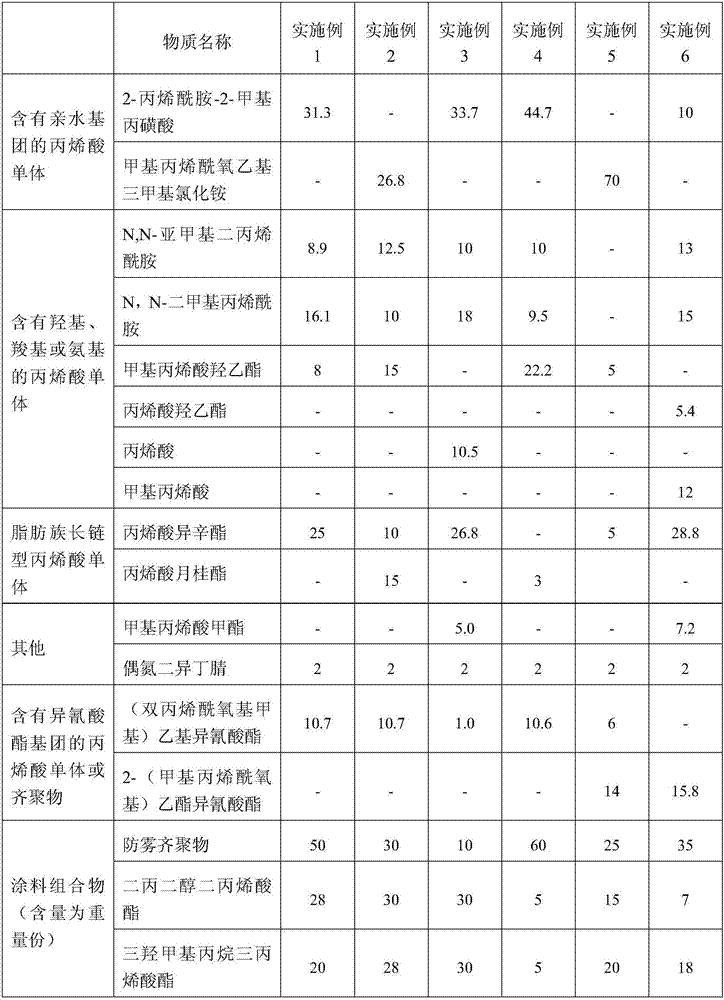

Embodiment 1

[0057] A kind of anti-fog oligomer of the present invention, after being polymerized by the acrylic acid monomer containing sulfonic acid group, the acrylic acid monomer containing hydroxyl group and amino group, isooctyl acrylate, and (bisacryloyloxymethyl) ethyl isocyanate The reaction is obtained; the weight average molecular weight of the anti-fog oligomer is 5,000-100,000.

[0058] In this embodiment, the anti-fog oligomer is obtained by reacting the following mass percentages of acrylic monomers: the mass percentage of acrylic monomers containing sulfonic acid groups is 31.3%, and the total of acrylic monomers containing hydroxyl and amino groups is The mass percentage is 33%, the mass percentage of isooctyl acrylate is 25%, and the mass percentage of (bisacryloyloxymethyl) ethyl isocyanate is 10.7%.

[0059] In this embodiment, the acrylic acid monomer containing sulfonic acid groups is 2-acrylamide-2-methylpropanesulfonic acid.

[0060] In this embodiment, the acrylic...

Embodiment 2

[0070] A kind of anti-fog oligomer of the present invention, by containing the acrylic acid monomer of quaternary ammonium salt group, containing the acrylic acid monomer of hydroxyl and amino group, isooctyl acrylate and lauryl acrylate polymerization, with (bisacryloyloxy It is obtained by reacting methyl) ethyl isocyanate; the weight average molecular weight of the anti-fog oligomer is 5,000-100,000.

[0071] In this embodiment, the anti-fog oligomer is obtained by reacting the following mass percent acrylic monomers: the mass percent of acrylic monomers containing quaternary ammonium salt groups is 26.8%, and the acrylic monomers containing hydroxyl and amino groups The total mass percentage is 37.5%, the total mass percentage of isooctyl acrylate and lauryl acrylate is 25%, and the mass percentage of (bisacryloyloxymethyl) ethyl isocyanate is 10.7%.

[0072] In this embodiment, the acrylic monomer containing a quaternary ammonium salt group is methacryloyloxyethyltrimethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com