Recombined bacillus alcalophilus, preparing method and application thereof, and method for preparing D-lactic acid

A technology based on alkalophilic bacillus and lactic acid, applied in the field of genetic engineering, can solve problems such as difficult to achieve effects, low yield and optical purity, and achieve the effects of simplifying the post-processing process, reducing environmental pollution, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] In the first aspect, the present invention provides a method for preparing a recombinant alkalophilic bacillus, wherein the method comprises: taking the alkalophilic bacillus producing L-lactic acid as the starting strain, and performing genetic engineering operations so that the starting strain does not express L-lactate dehydrogenase (L-LDH) expresses D-lactate dehydrogenase (D-LDH).

[0019] In the present invention, the starting bacterial strain can be various alkalophilic bacillus capable of producing L-lactic acid, wherein, the alkalophilic bacillus producing L-lactic acid can only express the gene encoding L-lactate dehydrogenase ( L-ldh) to produce L-lactic acid, or a strain that expresses both L-ldh and D-lactate dehydrogenase encoding genes (D-ldh) to produce L-lactic acid and D-lactic acid. The present invention has no particular limitation on the source of the L-lactic acid-producing alkalophilic Bacillus, which can be a conventional choice in the field, for...

Embodiment 1

[0051] This example is used to illustrate the construction of the recombinant alkalophilic Bacillus sp.N16-5Δldh-pDlac provided by the present invention.

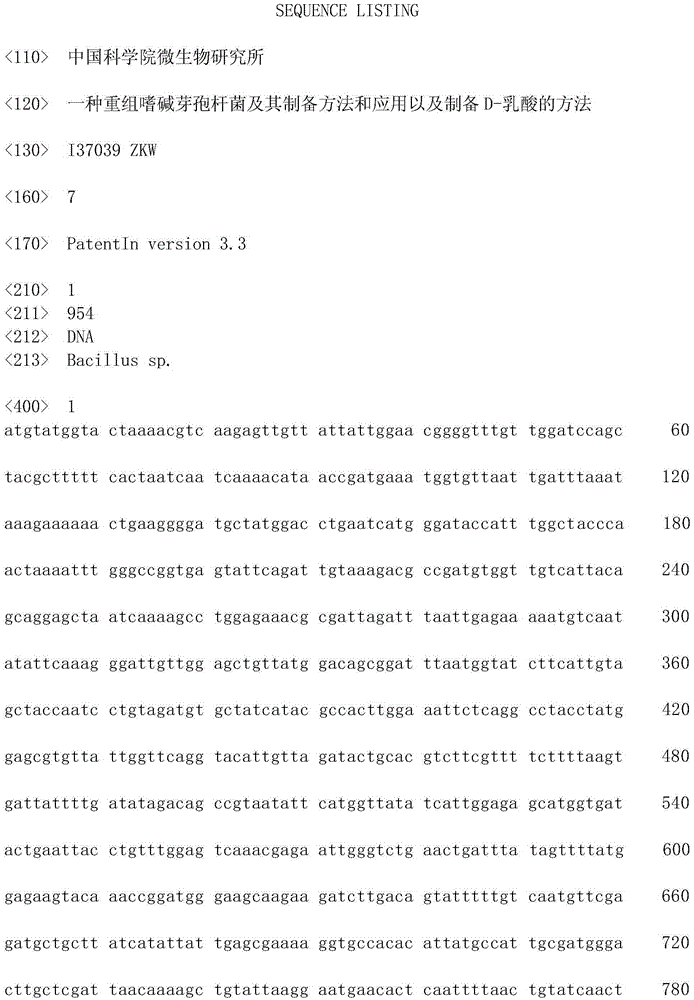

[0052] 1. Knockout of L-ldh gene in Bacillus sp.N16-5

[0053] According to the genome information of Bacillus sp.N16-5, the upstream and downstream primers of the L-ldh gene (SEQ ID NO:1) were designed, wherein the upstream primer was 5'-TATATAGAAAGGACGATGTAAATGAGTG-3'(SEQ ID NO:2) , the downstream primer is 5'-TCTTATCTTATTTGCCTGATCAAATGCC-3' (SEQ ID NO: 3); through the high-fidelity nucleic acid polymerase Pyrobest (Takara Company), using the genome of Bacillus sp.N16-5 as a template for PCR amplification To produce the L-ldh gene, the PCR amplification conditions were as follows: pre-denaturation at 95°C for 5 minutes, followed by 35 cycles at 95°C for 30s, 55°C for 30s, and 72°C for 90s; finally, extension at 72°C for 7 minutes. The size of the target gene was detected by 1% agarose gel electrophoresis, and the PCR pro...

Embodiment 2

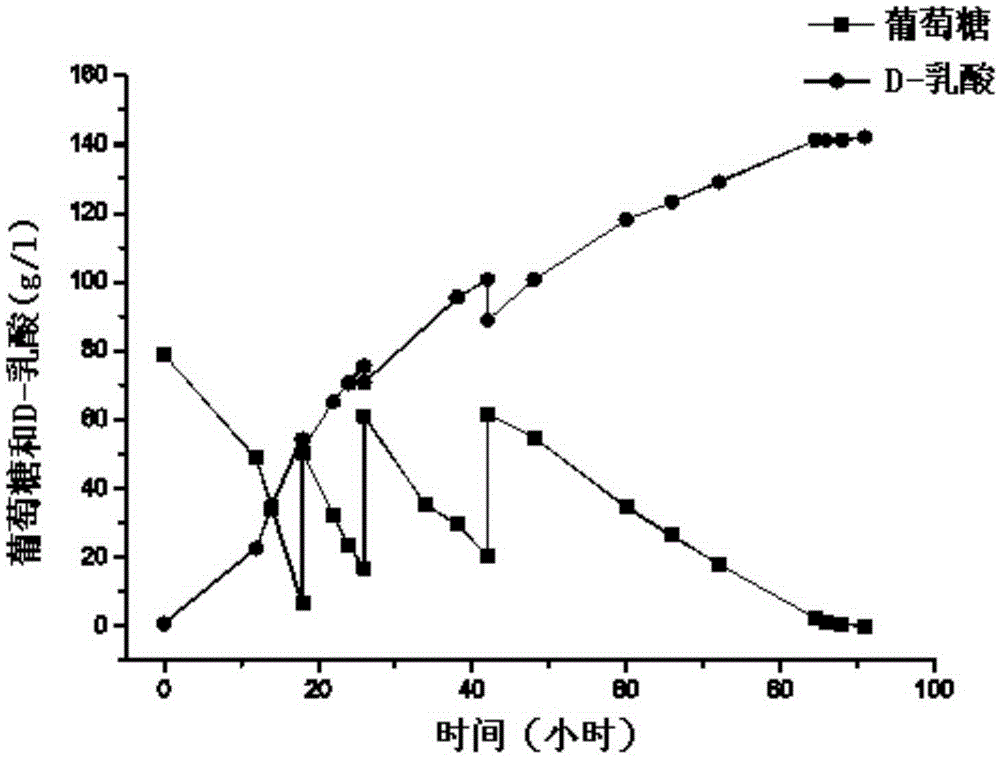

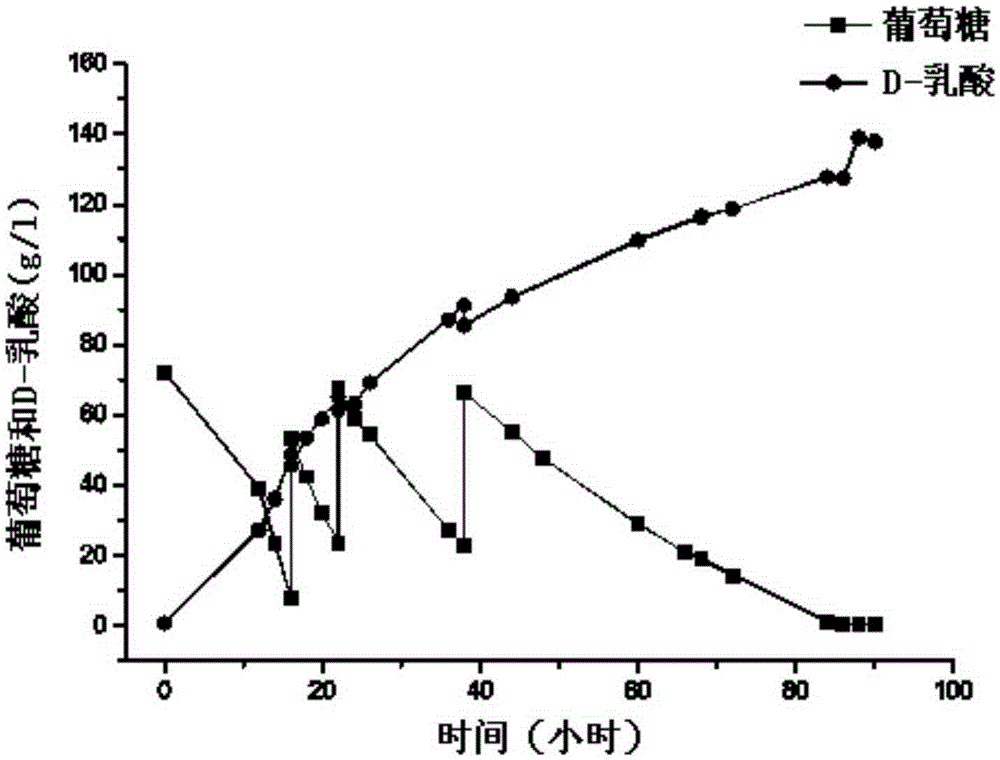

[0057]This example is used to illustrate the application of the recombinant alkalophilic Bacillus provided by the present invention in the production of D-lactic acid.

[0058] 1. Fermentation

[0059] 1) Activation culture: Inoculate the preserved recombinant Bacillus sp.N16-5Δldh-pDlac glycerin solution into a test tube containing 4mL seed medium with a volume ratio of 4% inoculum on a reciprocating shaker at 200 rpm Minutes, temperature 37°C, cultured for 12 hours;

[0060] 2) Seed culture: inoculate the liquid culture in step 1) in a 250 mL Erlenmeyer flask containing 100 mL of seed medium under aseptic conditions, and culture at 40° C. for 8 hours to obtain a seed culture solution;

[0061] 3) Fermentation culture: 700 mL of fermentation medium was added to a 1.4 liter fermenter of Multifors from Infors HT Company in Switzerland, and sterilized at 115° C. for 20 minutes. Filter-sterilized neutral protease (EC 3.4.24.28) was added at a final concentration of 0.15 g / L, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com