Carbon-coated titanium potassium phosphate nanoparticles and its preparation method and application

A nanoparticle and carbon-coated technology, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, to achieve the effects of improving electronic conductivity, excellent rate performance, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Carbon Coated KTi 2 (PO 4 ) 3 A method for preparing nanoparticles, comprising the steps of:

[0027] 1) Dissolve 3mmol of phosphoric acid in a mixed solution of 30mL of ethanol and 30mL of ethylene glycol, and stir until uniformly mixed.

[0028] 2) Add 2 mmol of potassium acetate and 1 mmol of tetrabutyl titanate to the mixed solution obtained in step 1) in sequence, and stir for 2 hours.

[0029] 3) The product obtained in step 2) is centrifugally filtered, the precipitate is washed twice with alcohol, and dried at 70° C. to obtain the precursor.

[0030] 4) Put the precursor obtained in step 3) into a tube furnace, heat it up to 750°C in argon and keep it warm for 2 hours, and then naturally cool to room temperature to obtain carbon-coated KTi 2 (PO 4 ) 3 nanoparticles.

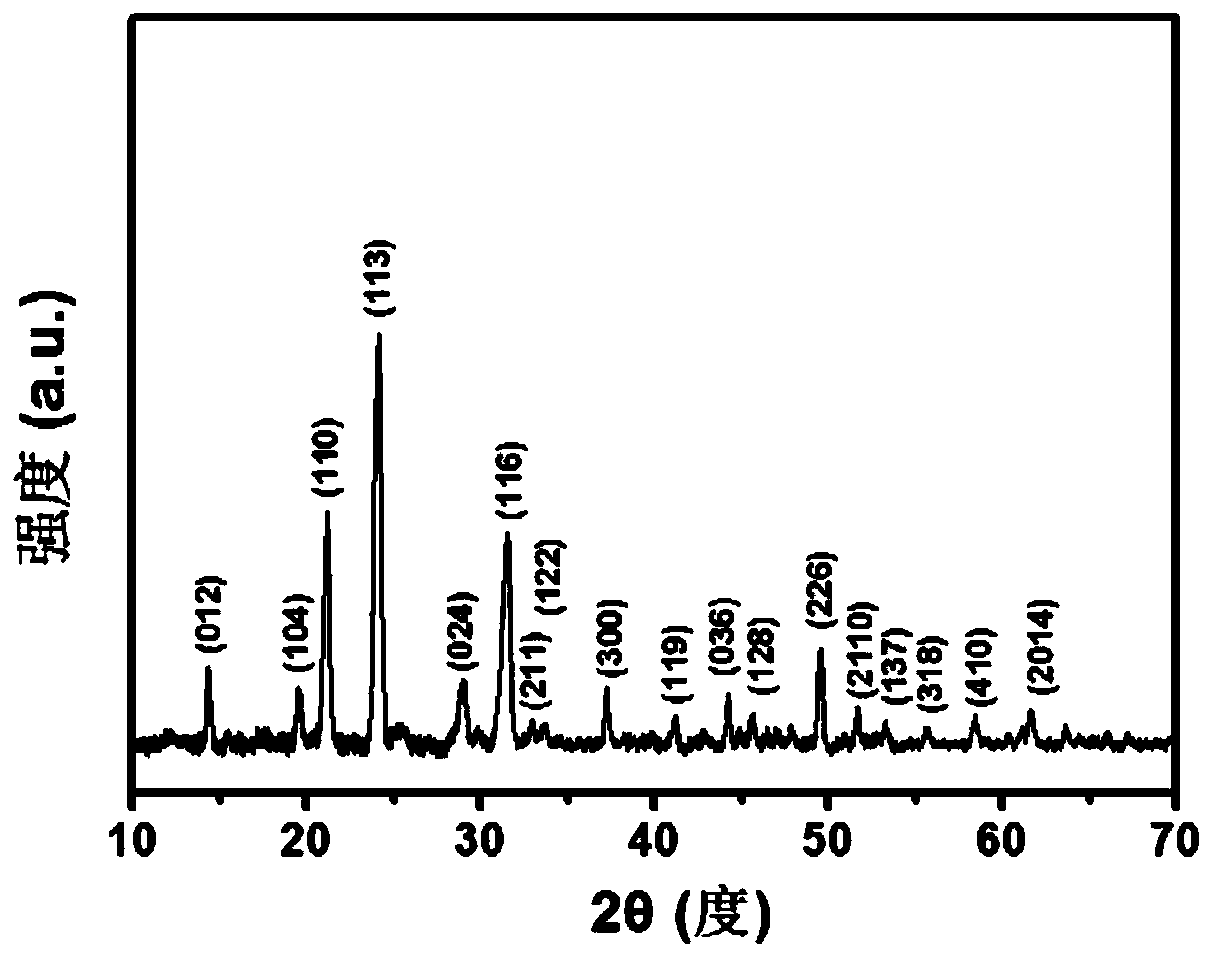

[0031] KTi coated with carbon of this example 2 (PO 4 ) 3 Nanoparticles as an example, the structure of which is determined by X-ray diffractometer. like figure 1 As shown, the X-ray di...

Embodiment 2

[0035] Carbon Coated KTi 2 (PO 4 ) 3 A method for preparing nanoparticles, comprising the steps of:

[0036] 1) Dissolve 3mmol of phosphoric acid in a mixed solution of 30mL of ethanol and 30mL of ethylene glycol, and stir until uniformly mixed.

[0037] 2) Add 2 mmol of potassium acetate and 1 mmol of tetrabutyl titanate to the mixed solution obtained in step 1) in sequence, and stir for 2 hours.

[0038] 3) The product obtained in step 2) is centrifugally filtered, the precipitate is washed twice with alcohol, and dried at 70° C. to obtain the precursor.

[0039] 4) Put the precursor obtained in step 3) into a tube furnace, heat it up to 750°C in argon and keep it warm for 2 hours, and then naturally cool to room temperature to obtain carbon-coated KTi 2 (PO 4 ) 3 nanoparticles.

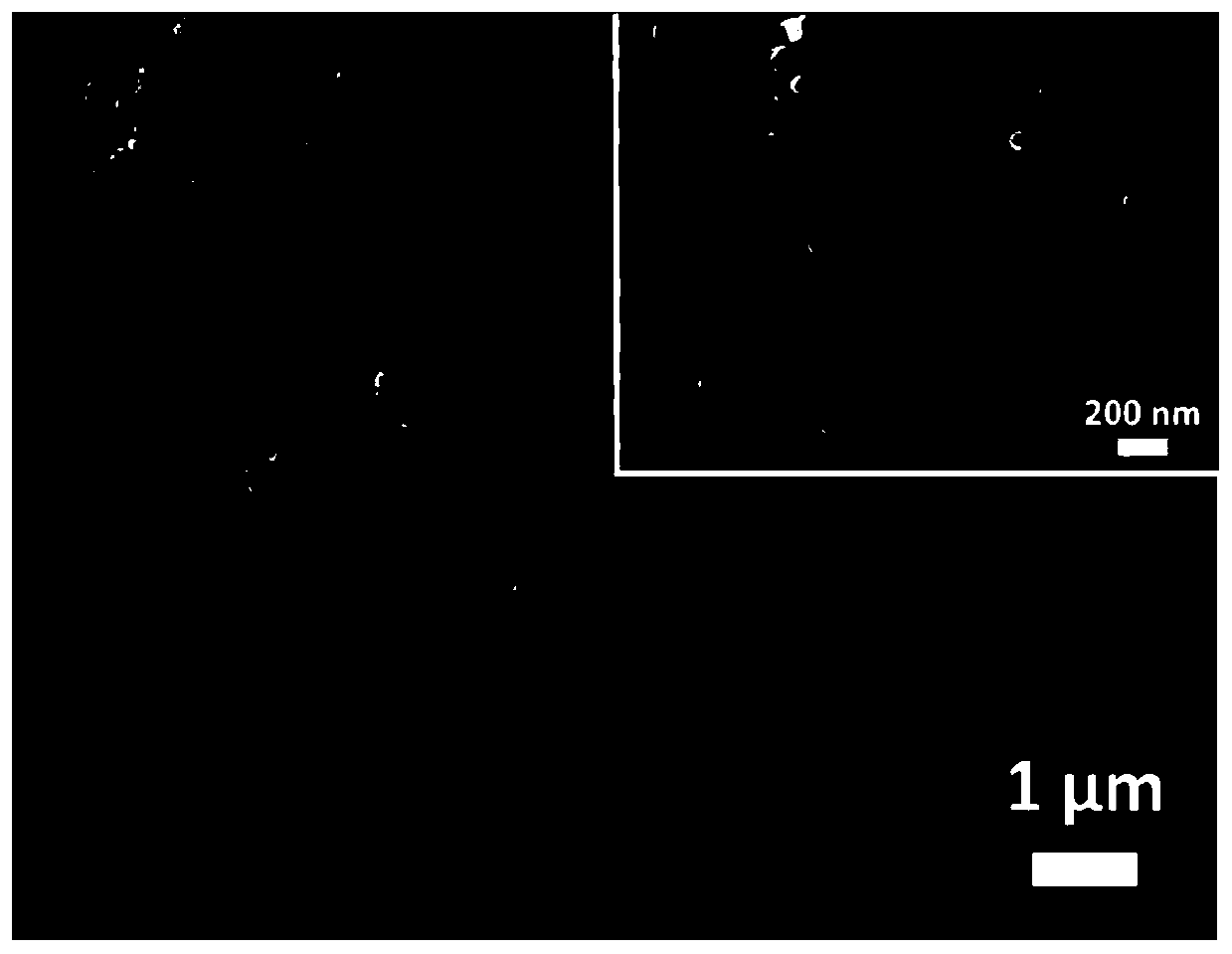

[0040] KTi coated with product carbon of the present invention 2 (PO 4 ) 3 Nanoparticles, for example, are small particles with a diameter of 100-200 nanometers.

[0041] With the carbon...

Embodiment 3

[0043] Carbon Coated KTi 2 (PO 4 ) 3 A method for preparing nanoparticles, comprising the steps of:

[0044] 1) Dissolve 3mmol of phosphoric acid in a mixed solution of 25mL of ethanol and 30mL of ethylene glycol, and stir until uniformly mixed.

[0045] 2) Add 2 mmol of potassium acetate and 1 mmol of tetrabutyl titanate to the mixed solution obtained in step 1) in sequence, and stir for 2 hours.

[0046] 3) The product obtained in step 2) is centrifugally filtered, the precipitate is washed twice with alcohol, and dried at 70° C. to obtain the precursor.

[0047] 4) Put the precursor obtained in step 3) into a tube furnace, heat it up to 750°C in argon and keep it warm for 2 hours, and then naturally cool to room temperature to obtain carbon-coated KTi 2 (PO 4 ) 3 nanoparticles.

[0048] KTi coated with product carbon of the present invention 2 (PO 4 ) 3 Nanoparticles, for example, are small particles with a diameter of 100-200 nanometers.

[0049] With the carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com