Carbon-cladded potassium titanyl phosphate nano particle, as well as preparation method and application thereof

A nanoparticle, carbon coating technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, to achieve the effect of promoting marketization, high electronic conductivity, and improving electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Carbon Coated KTi 2 (PO 4 ) 3 A method for preparing nanoparticles, comprising the steps of:

[0027] 1) Dissolve 3mmol of phosphoric acid in a mixed solution of 30mL of ethanol and 30mL of ethylene glycol, and stir until uniformly mixed.

[0028] 2) Add 2 mmol of potassium acetate and 1 mmol of tetrabutyl titanate to the mixed solution obtained in step 1) in sequence, and stir for 2 hours.

[0029] 3) The product obtained in step 2) is centrifugally filtered, the precipitate is washed twice with alcohol, and dried at 70° C. to obtain the precursor.

[0030] 4) Put the precursor obtained in step 3) into a tube furnace, heat it up to 750°C in argon and keep it warm for 2 hours, and then naturally cool to room temperature to obtain carbon-coated KTi 2 (PO 4 ) 3 nanoparticles.

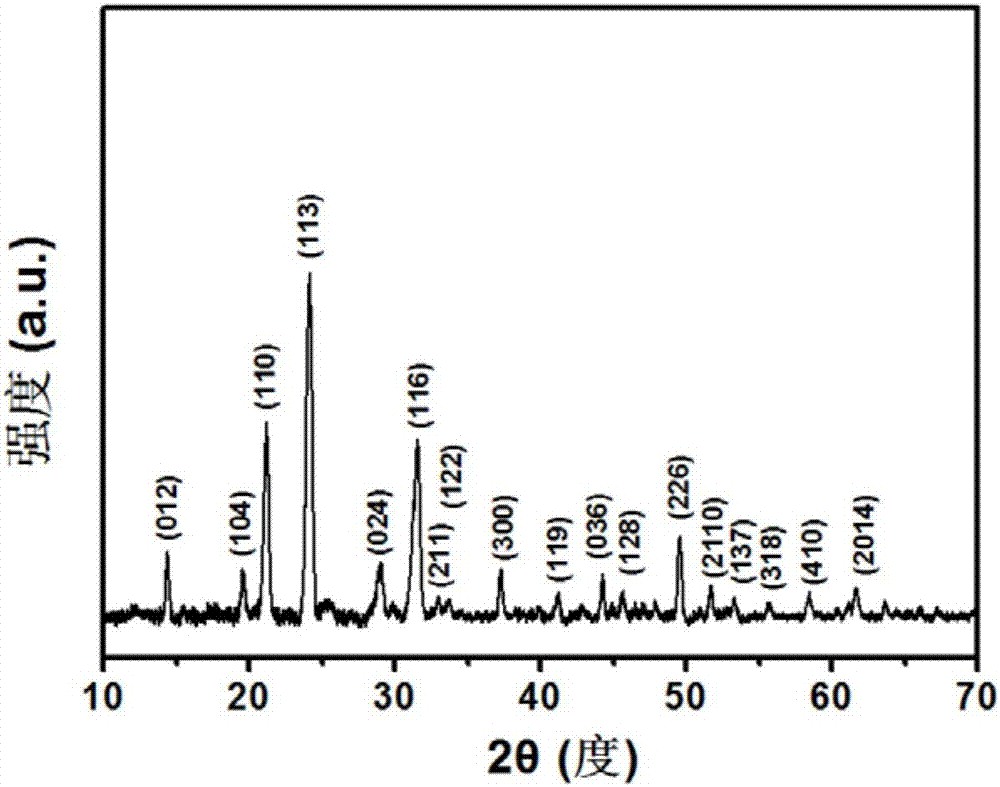

[0031] KTi coated with carbon of this example 2 (PO 4 ) 3 Nanoparticles as an example, the structure of which is determined by X-ray diffractometer. Such as figure 1 As shown, the X-ray...

Embodiment 2

[0035] Carbon Coated KTi 2 (PO 4 ) 3 A method for preparing nanoparticles, comprising the steps of:

[0036] 1) Dissolve 3mmol of phosphoric acid in a mixed solution of 30mL of ethanol and 30mL of ethylene glycol, and stir until uniformly mixed.

[0037] 2) Add 2 mmol of potassium acetate and 1 mmol of tetrabutyl titanate to the mixed solution obtained in step 1) in sequence, and stir for 2 hours.

[0038] 3) The product obtained in step 2) is centrifugally filtered, the precipitate is washed twice with alcohol, and dried at 70° C. to obtain the precursor.

[0039] 4) Put the precursor obtained in step 3) into a tube furnace, heat it up to 750°C in argon and keep it warm for 2 hours, and then naturally cool to room temperature to obtain carbon-coated KTi 2 (PO 4 ) 3 nanoparticles.

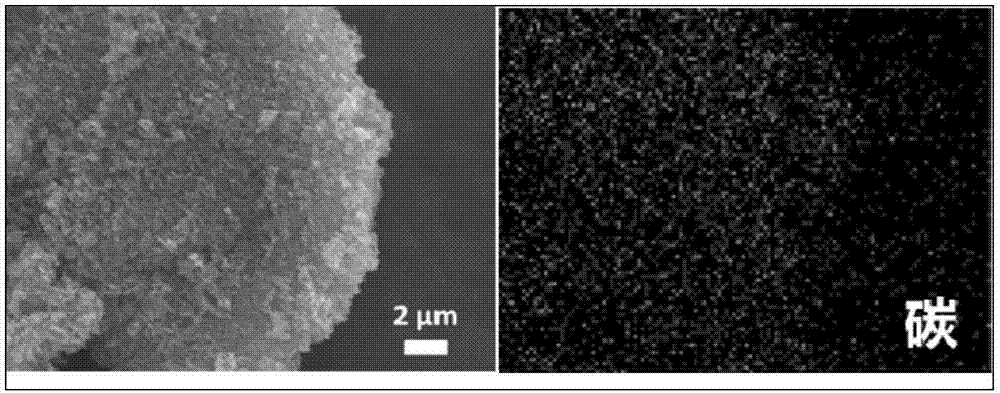

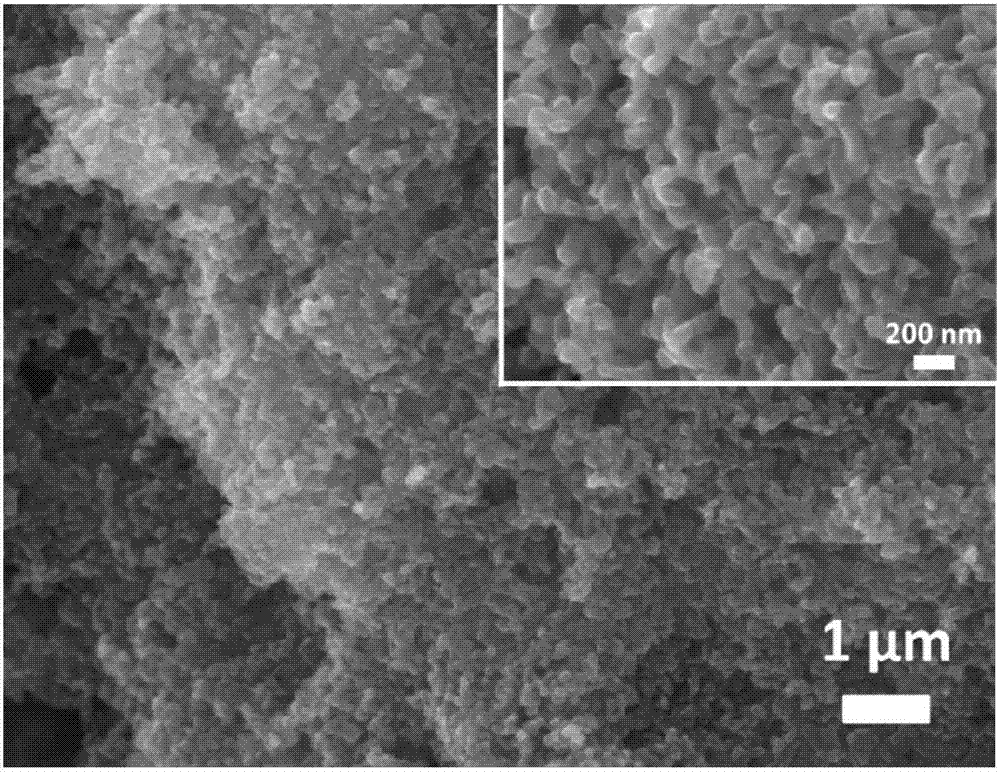

[0040] KTi coated with product carbon of the present invention 2 (PO 4 ) 3 Nanoparticles, for example, are small particles with a diameter of 100-200 nanometers.

[0041] With the carbon...

Embodiment 3

[0043] Carbon Coated KTi 2 (PO 4 ) 3 A method for preparing nanoparticles, comprising the steps of:

[0044] 1) Dissolve 3mmol of phosphoric acid in a mixed solution of 25mL of ethanol and 30mL of ethylene glycol, and stir until uniformly mixed.

[0045] 2) Add 2 mmol of potassium acetate and 1 mmol of tetrabutyl titanate to the mixed solution obtained in step 1) in sequence, and stir for 2 hours.

[0046] 3) The product obtained in step 2) is centrifugally filtered, the precipitate is washed twice with alcohol, and dried at 70° C. to obtain the precursor.

[0047] 4) Put the precursor obtained in step 3) into a tube furnace, heat it up to 750°C in argon and keep it warm for 2 hours, and then naturally cool to room temperature to obtain carbon-coated KTi 2 (PO 4 ) 3 nanoparticles.

[0048] KTi coated with product carbon of the present invention 2 (PO 4 ) 3 Nanoparticles, for example, are small particles with a diameter of 100-200 nanometers.

[0049] With the carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com