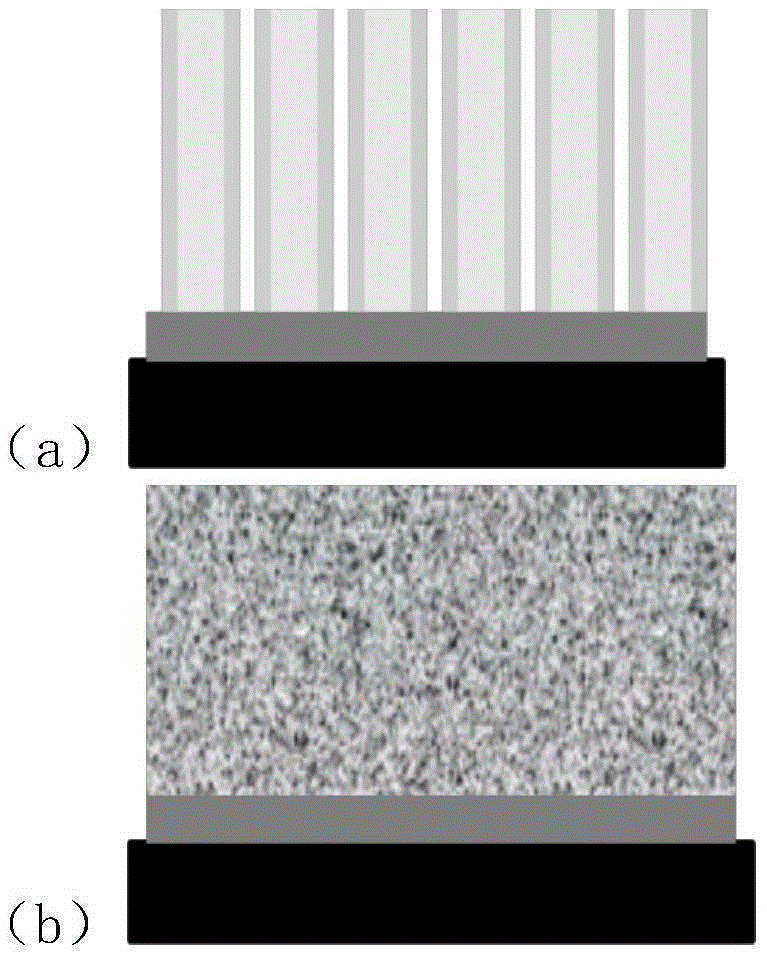

Ordered membrane electrode and preparation and application thereof

A membrane electrode, ordered array technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of high catalyst loading, large mass transfer resistance, affecting the overall performance of the battery, etc., and achieve easy amplification and reduce catalyst loading. , the effect of improving catalyst utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] 1) Preparation of gas diffusion layer:

[0065] Immerse Toray carbon paper in 5% PTFE aqueous solution, take it out and air-dry after fully impregnated, and weigh it. Repeat the above steps repeatedly until the PTFE load is about 10%. Mix XC-72 carbon powder with 60% PTFE aqueous solution relative to the total mass, dilute with ethanol, disperse under ultrasonic conditions for 30 minutes and stir evenly. The above-mentioned hydrophobic treated carbon paper was placed on a glass plate and fixed, and then the slurry was scraped on the surface of the carbon paper, weighed after air drying, and the above steps were repeated until the carbon powder loading was 0.4mg / cm2, and the gas diffusion layer was obtained.

[0066] 2) Preparation of ordered array carrier

[0067] The ordered array was prepared by chemical polymerization, the above gas diffusion layer was placed in a solution containing 0.01M aniline, 1M perchloric acid, and 0.007M ammonium persulfate, and reacted at ...

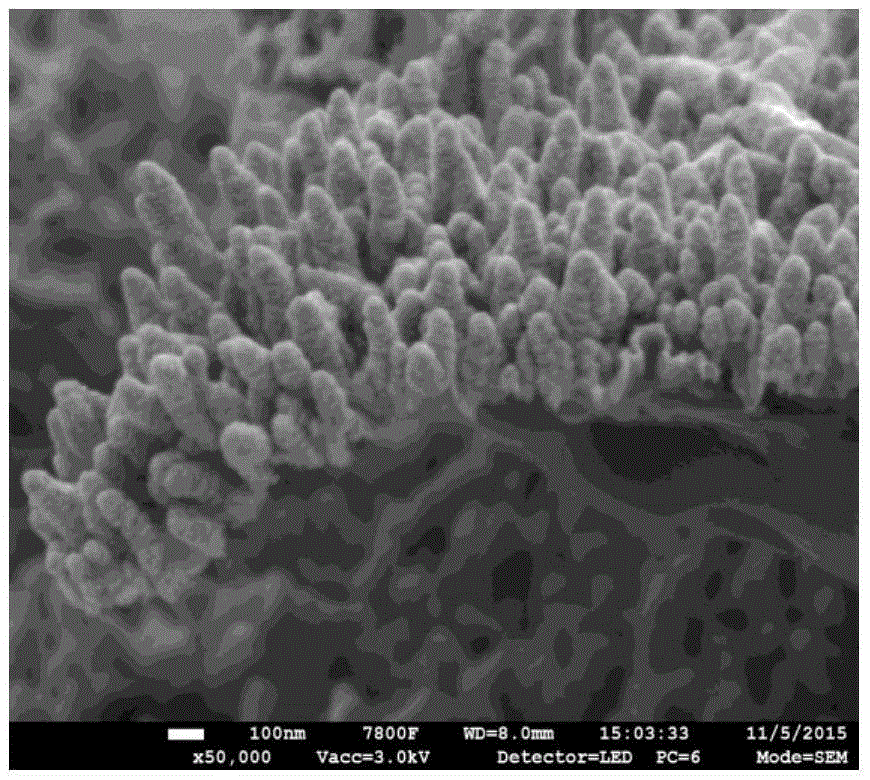

Embodiment 2

[0071] The difference from the above-mentioned Example 1 is that: the concentration of aniline is 0.5M, and an ordered array carrier of conical structures is obtained, which is in a parallel arrangement structure: 85 conical structures per square micron; the height of the conical structures is 500nm; the diameter of the bottom of the conical structures is 110nm; Conductivity is 68S cm -1 .

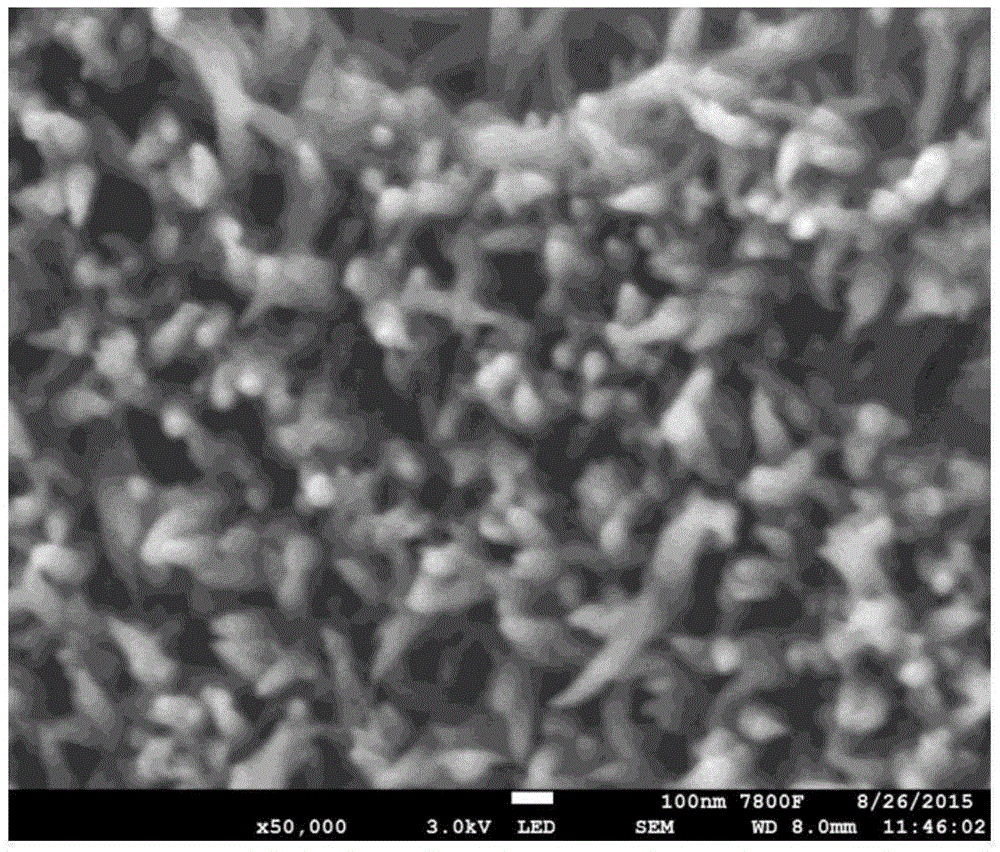

Embodiment 3

[0073] The difference from the above Example 1 is that the reaction temperature during the preparation of the ordered carrier is 25°C, and the ordered array carrier of the conical structure is obtained, which is in the form of a rattan cluster structure: 89 conical structures per square micron; the height of the conical structure is 177nm; the diameter of the bottom of the conical structure is 56nm; the conductivity is 35S cm -1 . .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com