Processing method of high-calcium minced fish product

A processing method and high-calcium fish technology, applied in food science and other fields, can solve the problems of fish bones softening fish meat/fish bones, etc., to achieve the effect of enhancing uniformity, reducing discomfort, and improving the degree of fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

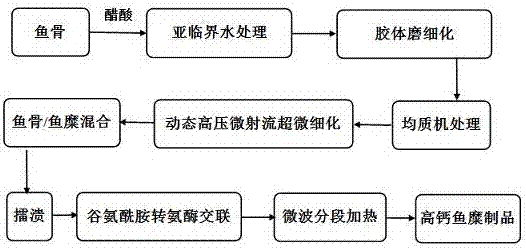

Image

Examples

Embodiment 1

[0030] 1. Subcritical water combined with acetic acid to treat fish bones

[0031] (1) Preparation of acetic acid solution: Dilute anhydrous acetic acid with distilled water to prepare 0.5 M acetic acid solution;

[0032] (2) Mixing of fish bone and acetic acid solution: mix the fish bone and acetic acid solution according to the solid-to-liquid ratio of 1:3;

[0033] (3) Subcritical water treatment: Subcritical water treatment was performed on the mixture of fish bones and acetic acid. The subcritical water temperature was set at 160 °C and the treatment time was 1.0 h.

[0034] 2. Dynamic high-pressure micro-jet ultra-fine fishbone

[0035] (1) Acid solution neutralization: use 0.5 M sodium carbonate solution to neutralize the pH value of the fish bone solution to 6.5;

[0036] (2) Dynamic high-pressure micro-jet treatment: the colloid mill was used to treat the fishbone mixture twice, and then a 20 MPa homogenizer was used to treat it twice, and then the high-pressure mic...

Embodiment 2

[0045] 1. Subcritical water combined with acetic acid to treat fish bones

[0046] (1) Preparation of acetic acid solution: Dilute anhydrous acetic acid with distilled water to prepare 1.0 M acetic acid solution;

[0047] (2) Mixing of fish bones and acetic acid solution: mix the fish bones and acetic acid solution according to the solid-to-liquid ratio of 1:2;

[0048] (3) Subcritical water treatment: Subcritical water treatment was performed on the mixture of fish bones and acetic acid. The subcritical water temperature was set at 170 °C and the treatment time was 1.0 h.

[0049] 2. Dynamic high-pressure micro-jet ultra-fine fishbone

[0050] (1) Acid solution neutralization: Use 1.0 M sodium carbonate solution to neutralize the pH value of the fishbone solution to 7.0;

[0051] (2) Dynamic high-pressure micro-jet treatment: the colloid mill was used to treat the fishbone mixture three times, and then a 30 MPa homogenizer was used to process it twice, and then the high-pre...

Embodiment 3

[0060] 1. Subcritical water combined with acetic acid to treat fish bones

[0061] (1) Preparation of acetic acid solution: Dilute anhydrous acetic acid with distilled water to prepare 0.6 M acetic acid solution;

[0062] (2) Mixing fish bones and acetic acid solution: mix the fish bones and acetic acid solution according to the solid-to-liquid ratio of 1:5;

[0063] (3) Subcritical water treatment: subcritical water treatment was performed on the mixture of fish bone and acetic acid, the subcritical water temperature was set at 150 °C, and the treatment time was 1.5 h.

[0064] 2. Dynamic high-pressure micro-jet ultra-fine fishbone

[0065] (1) Acid solution neutralization: Use 1.0 M sodium carbonate solution to neutralize the pH value of the fishbone solution to 5.5;

[0066](2) Dynamic high-pressure micro-jet treatment: the colloid mill was used to treat the fishbone mixture three times, and then a 40 MPa homogenizer was used to process it twice, and then the high-pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com