A kind of preparation method of small particle size starch microsphere

A technology of starch microspheres and small particle size, which is applied in the field of preparation of small particle size starch microspheres, and can solve the problems of no small particle size starch microspheres, large average particle size of starch microspheres, and poor product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

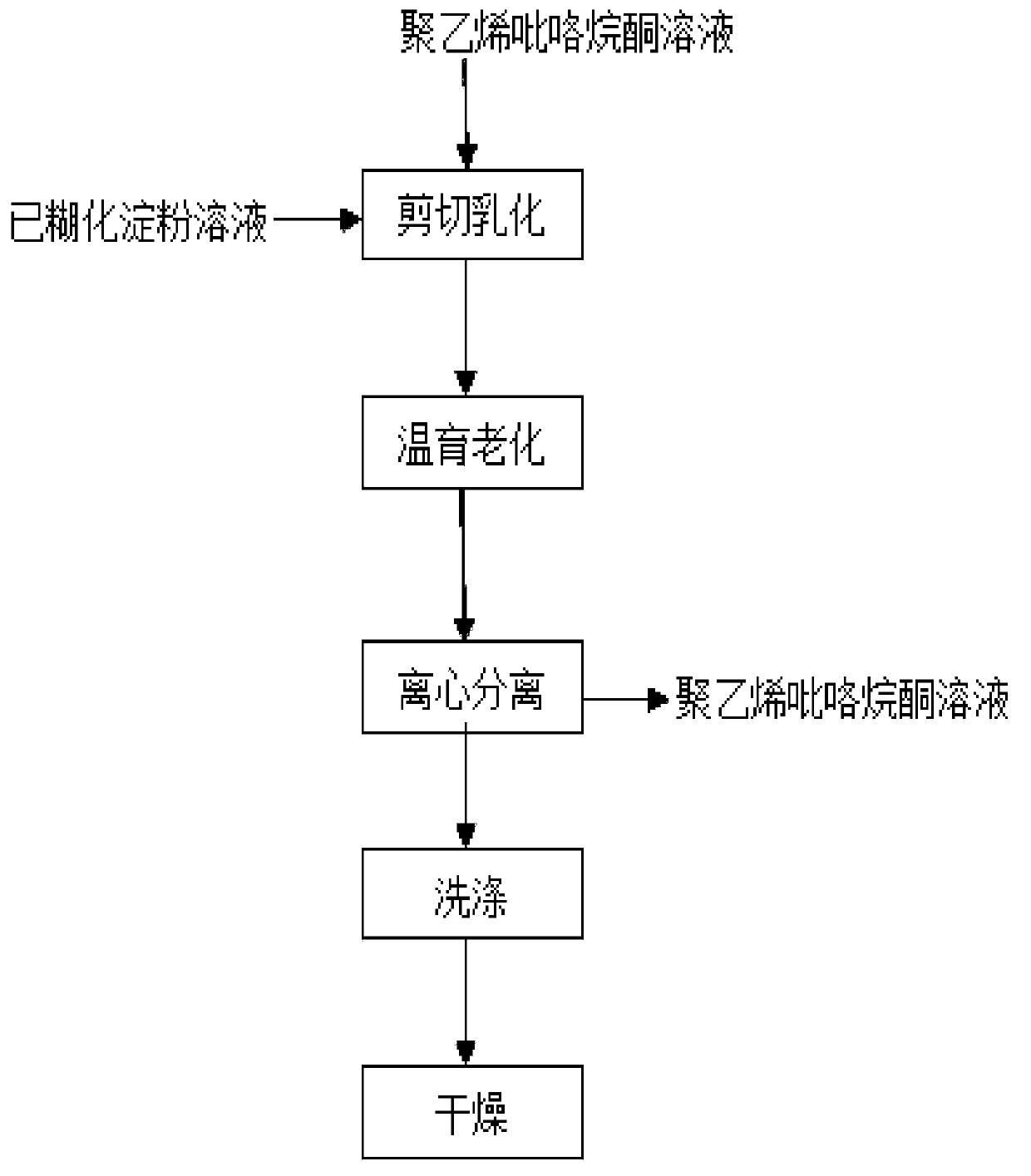

Method used

Image

Examples

Embodiment 1

[0028] A preparation method for small-diameter starch microspheres, comprising the following steps:

[0029] (1) Preparation of starch solution: the modified starch obtained after acid treatment of soluble potato starch was prepared into a suspension with a mass fraction of 17.5%, and gelatinized by heating in a boiling water bath for 15 minutes to obtain a starch solution;

[0030] (2) Preparation of polyvinylpyrrolidone solution: polyvinylpyrrolidone with a weight average molecular weight of 24000 and deionized water are prepared into a polyvinylpyrrolidone solution with a mass fraction of 38%;

[0031] (3) Emulsion emulsification: In parts by volume, pour 1 part of the starch solution that has been cooled to 55°C into 10 parts of the polyvinylpyrrolidone solution at 55°C, and then use a high-shear emulsifier at a speed of 6000 rpm Lower emulsification for 30 seconds to obtain a two-phase emulsion;

[0032] (4) Regeneration and solidification into balls and separation and w...

Embodiment 2

[0038] A preparation method for small-diameter starch microspheres, comprising the following steps:

[0039] (1) Preparation of starch solution: the modified starch obtained after acid treatment of soluble corn starch was prepared into a suspension with a mass fraction of 17.5%, and gelatinized by heating in a boiling water bath for 15 minutes to obtain a starch solution;

[0040](2) Polyvinylpyrrolidone solution preparation: polyvinylpyrrolidone with a weight average molecular weight of 10000 and deionized water are prepared into a polyvinylpyrrolidone solution with a mass fraction of 45%;

[0041] (3) Emulsion emulsification: In parts by volume, pour 1 part of starch solution that has been cooled to 55°C into 10 parts of polyvinylpyrrolidone solution at 55°C, and then use a high-shear emulsifier at a speed of 8000 rpm Lower emulsification for 10 seconds to obtain a two-phase emulsion;

[0042] (4) Regeneration and solidification into balls and separation and washing: put th...

Embodiment 3

[0048] A preparation method for small-diameter starch microspheres, comprising the following steps:

[0049] (1) Preparation of starch solution: the modified starch obtained after acid treatment of soluble tapioca starch was prepared into a suspension with a mass fraction of 10%, and gelatinized by heating in a boiling water bath for 15 minutes to obtain a starch solution;

[0050] (2) Preparation of polyvinylpyrrolidone solution: polyvinylpyrrolidone with a weight average molecular weight of 24000 and deionized water are prepared into a polyvinylpyrrolidone solution with a mass fraction of 35%;

[0051] (3) Emulsion emulsification: In parts by volume, pour 1 part of starch solution that has been cooled to 55°C into 8 parts of polyvinylpyrrolidone solution at 55°C, and then use a high-shear emulsifier at a speed of 10,000 rpm Lower emulsification for 20 seconds to obtain a two-phase emulsion;

[0052] (4) Regeneration and solidification into balls and separation and washing: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com