A kind of mg-al-sn-sb magnesium alloy and preparation method thereof

A mg-al-sn-sb, magnesium alloy technology, applied in the field of light metal materials, can solve the problems of high cost of rare earth elements, reduced resources, etc., achieve high microhardness and melting point, inhibit grain growth, and thermal stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

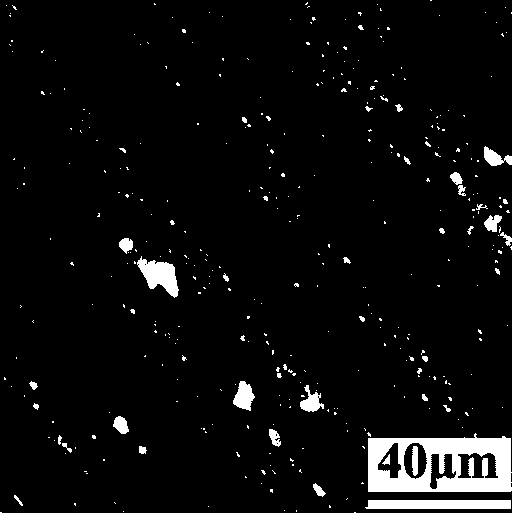

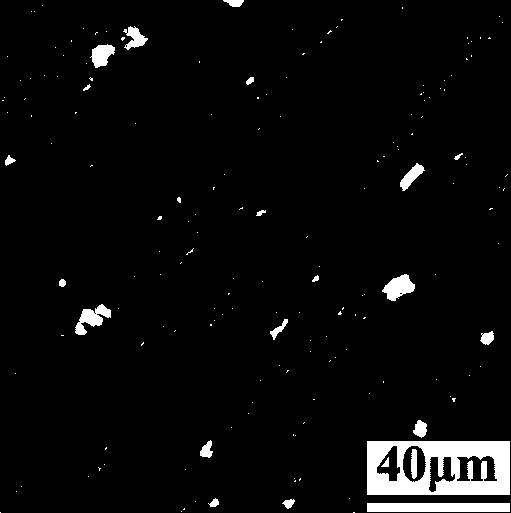

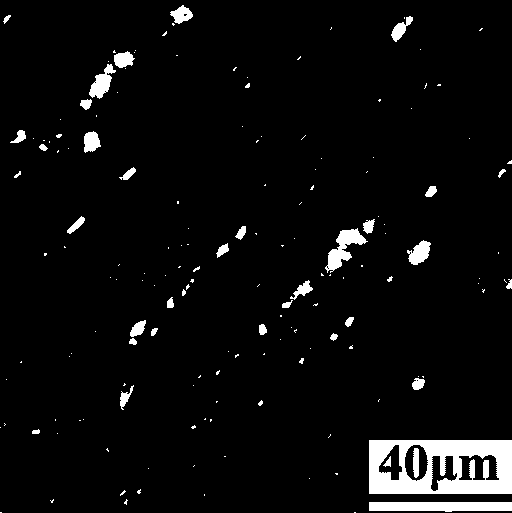

Image

Examples

preparation example Construction

[0033] The present invention also provides a method for preparing a Mg-Al-Sn-Sb magnesium alloy, comprising the following steps:

[0034] Step S1, alloy smelting: first, according to the mass percentage composition of the Mg-Al-Sn-Sb magnesium alloy, combined with the burning loss rate of elements, calculate the ratio of alloy elements, and select and weigh alloy raw materials magnesium ingots, aluminum ingots, tin and Antimony; secondly, put the graphite crucible into the vacuum induction melting furnace, then put the stainless steel crucible loaded with the alloy raw material into the graphite crucible, and vacuumize the vacuum induction melting furnace so that the vacuum degree is less than 0.1Pa , introducing an inert protective gas, starting to heat to the alloy melting temperature, so that the alloy raw material is fully melted, and an alloy melt is obtained; finally, the stainless steel crucible containing the alloy melt is cooled, extruded, and an ingot wagon is obtaine...

Embodiment 1

[0042] A kind of Mg-Al-Sn-Sb magnesium alloy, its mass percentage is composed of:

[0043] Al: 10.19%;

[0044] Sn: 5.1%;

[0045] Sb: 0%;

[0046] The rest is Mg and unavoidable impurities, and the total amount of unavoidable impurities is less than 0.05%.

[0047] The present embodiment Mg-Al-Sn-Sb magnesium alloy obtains by following preparation method:

[0048] Step S1, alloy smelting: firstly, according to the mass percentage composition of the Mg-Al-Sn-Sb magnesium alloy, combined with the burning loss rate of elements, the ratio of alloy elements is calculated, and the alloy raw materials magnesium ingot, aluminum ingot and tin are respectively weighed; Then, the graphite crucible is put into the vacuum induction melting furnace, and then the stainless steel crucible loaded with the alloy raw material is put into the graphite crucible, and the vacuum is evacuated so that the vacuum degree of the vacuum induction melting furnace is less than 0.1Pa. Enter the inert pr...

Embodiment 2

[0053] A kind of Mg-Al-Sn-Sb magnesium alloy, its mass percentage is composed of:

[0054] Al: 10.19%;

[0055] Sn: 4.99%;

[0056] Sb: 0.18%;

[0057] The rest is Mg and unavoidable impurities, and the total amount of unavoidable impurities is less than 0.05%.

[0058] The present embodiment Mg-Al-Sn-Sb magnesium alloy obtains by following preparation method:

[0059] Step S1, alloy smelting: First, according to the mass percentage composition of the Mg-Al-Sn-Sb magnesium alloy, combined with the burning loss rate of the elements, the ratio of alloy elements is calculated, and the alloy raw materials magnesium ingot, aluminum ingot, tin and Antimony; secondly, put the graphite crucible into the vacuum induction melting furnace, then put the stainless steel crucible loaded with the alloy raw material into the graphite crucible, and vacuumize the vacuum induction melting furnace so that the vacuum degree is less than 0.1Pa , into the inert protective gas argon, start heatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com