Culturing method for high-yield of grass carps

A breeding method and technology of grass carp, applied in fish farming, climate change adaptation, animal feed, etc., can solve problems affecting the environment, polluting water quality, and harming consumers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

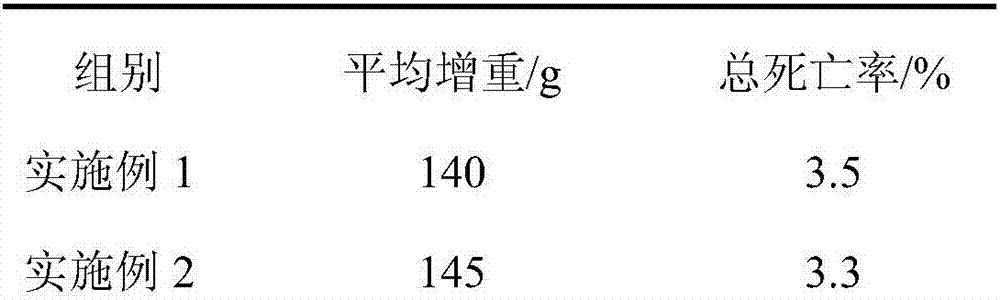

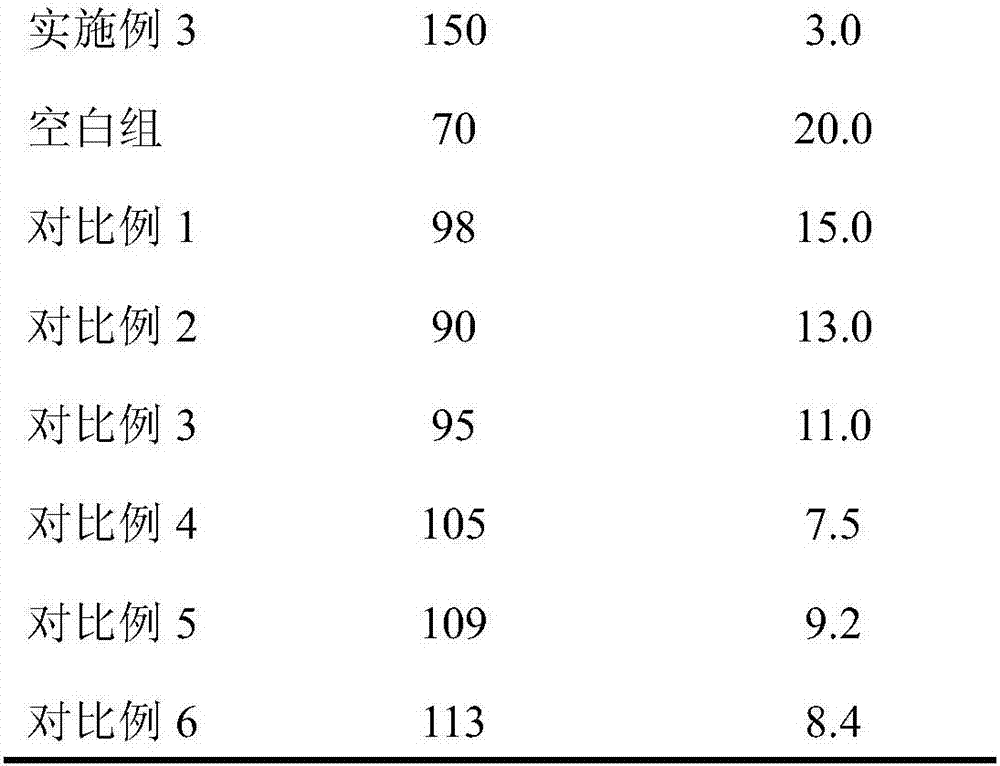

Examples

Embodiment 1

[0044] 1. Feed preparation:

[0045] The feed is mainly made of the following raw materials in parts by weight: 13 parts of beef thorn, 15 parts of mountain horse vegetable, 13 parts of old mountain celery, 15 parts of Chinese cabbage, 17 parts of gray vegetable, 15 parts of Sudan grass, 17 parts of lemongrass, wormwood 12 parts, 10 parts of Vitex japonica, 10 parts of Shijunzi, 10 parts of scorpion grass, 15 parts of mulberry, 15 parts of deer grass, 10 parts of knotweed, 10 parts of Gentiana, 10 parts of sugar beet meal, 4 parts of rice bran, 4 parts of wheat bran 1 part, 6 parts of soybean, 8 parts of silkworm chrysalis, 2 parts of starch, 8 parts of corn flour, 10 parts of earthworm powder and 1 part of microorganism mixed with lactic acid bacteria, yeast and photosynthetic bacteria in equal weight ratio.

[0046] The above-mentioned ratio is expected to be prepared into feed using the following method, which specifically includes the following steps:

[0047] (1) Fresh b...

Embodiment 2

[0064] 1. Feed preparation:

[0065] The feed is mainly made of the following raw materials in parts by weight: 14 parts of beef thorn, 16 parts of mountain horse vegetable, 14 parts of old celery, 16 parts of Chinese cabbage, 18 parts of gray vegetable, 16 parts of Sudan grass, 18 parts of lemongrass, wormwood 13 parts, 12 parts of Vitex japonica, 13 parts of Shi Junzi, 13 parts of scorpion grass, 16 parts of mulberry, 16 parts of deer grass, 13 parts of knotweed, 13 parts of Gentiana, 11 parts of sugar beet meal, 4.5 parts of rice bran, 4.5 parts of wheat bran 7 parts of soybeans, 9 parts of silkworm chrysalis, 2.5 parts of starch, 9 parts of corn flour, 11 parts of earthworm powder and 1.5 parts of microorganisms mixed with lactic acid bacteria, yeast and photosynthetic bacteria in equal weight ratios.

[0066] The above-mentioned ratio is expected to be prepared into feed using the following method, which specifically includes the following steps:

[0067] (1) Fresh beef ...

Embodiment 3

[0084] 1. Feed preparation:

[0085] The feed is mainly made of the following raw materials in parts by weight: 15 parts of cow's mouth thorn, 17 parts of mountain horse vegetable, 15 parts of old mountain celery, 17 parts of Chinese cabbage, 20 parts of gray vegetable, 17 parts of Sudan grass, 20 parts of lemongrass, wormwood 14 parts, 13 parts of Vitex japonica, 15 parts of Shi Junzi, 15 parts of scorpion grass, 17 parts of mulberry, 17 parts of chrysanthemum, 15 parts of knotweed, 15 parts of Gentiana, 12 parts of beet meal, 5 parts of rice bran, 5 parts of wheat bran 8 parts of soybeans, 10 parts of silkworm chrysalis, 3 parts of starch, 10 parts of corn flour, 12 parts of earthworm powder and 2 parts of microorganisms mixed with lactic acid bacteria, yeast and photosynthetic bacteria in equal weight ratios.

[0086] The above-mentioned ratio is expected to be prepared into feed using the following method, which specifically includes the following steps:

[0087] (1) Fres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com