Industrialized preparation method of pawpaw enzyme preparation, and applications thereof

A technology of papaya enzyme and papaya, applied in the field of industrial preparation of papaya enzyme preparations, to achieve the effects of reduced water and electricity consumption, stable product quality, and prominent sour taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

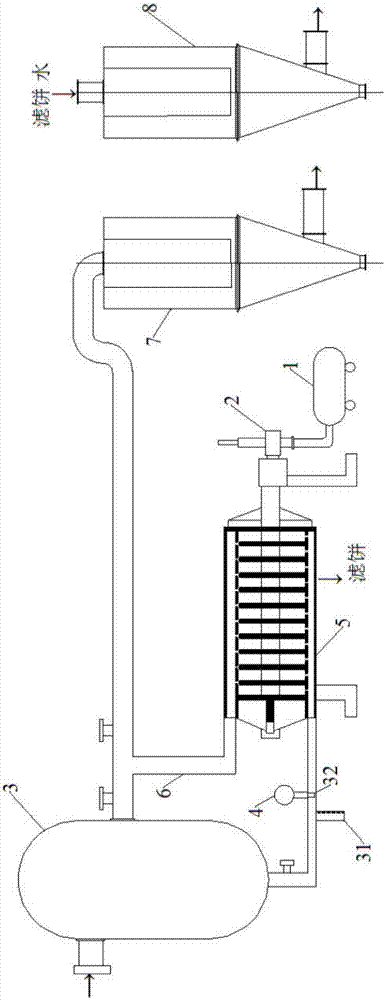

[0036] Please refer to figure 1 , the present embodiment provides a kind of industrialized preparation method of papaya enzyme preparation, comprises the following steps:

[0037] (1) Set VW-0.42 / 7 oil-free air compressor 1 (discharge pressure 0.7Mpa, volume flow 0.42m3 / min), A27W-10T spring safety valve (TS) 2, with 3251.072.090 pressure sensor 31 and LZJ glass rotameter 32 50L storage tank 3, pressure gauge 4, BMS0.5 / 290-UB reinforced polypropylene plate and frame filter press 5 (filter area 0.5m 2 , the total volume of the filter chamber is 7.5L), 80 mesh filter cloth, return pipe 6, the first spray dryer 7, and the second spray dryer 8; the spring safety valve 2 is connected to the oil-free air compressor 1 and the plate frame filter press 5, the pressure gauge 4 is respectively connected to the storage tank 3 and the plate and frame filter press 5, the storage tank 3 is also connected to the plate and frame filter 5 through the return pipe 6, and the 80-mesh filter cloth...

Embodiment 2

[0048] This example is basically the same as Example 1, the difference being that the inlet temperature in step (5) of the industrialized preparation method of papaya enzyme preparation is 125° C., and other steps are the same as in Example 1, and will not be repeated here.

Embodiment 3

[0050] This example is basically the same as Example 1, the difference being that the inlet temperature in step (5) of the industrialized preparation method of papaya enzyme preparation is 115° C., and other steps are the same as Example 1, and will not be repeated here.

[0051] The papaya lipase that embodiment 1-3 is made contrasts, compares the influence of different material inlet temperatures on the preparation of papaya lipase, calculates yield, specific enzyme activity, lipase recovery rate and water content, wherein, yield ( %)=spray-dried papaya lipase weight / weight of papaya milk×100%, enzyme activity recovery (%)=(spray-dried papaya lipase weight*specific enzyme activity) / (weight*specific enzyme activity of papaya milk)× 100%, list the results as follows:

[0052]

[0053]

[0054] It can be seen from the above table that the higher the material inlet temperature, the higher the yield of CPL and the higher the total recovery of lipase. The higher the inlet t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com