Clustered polyaniline nanofiber composite carbon electrode and preparation method and application thereof

A nanofiber and polyaniline technology, which is applied in the field of clustered polyaniline nanofiber composite carbon electrodes and its preparation, can solve the problems of poor electrical conductivity and biocompatibility, and achieves improved electrochemical reaction rate, good adsorption performance, technically simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Dissolve 0.113g of tartaric acid in 40ml of water, stir magnetically at room temperature for 0.5h; add 273.5 microliters of aniline, continue stirring for 30min, and then cool in an ice bath for 10min; dissolve 0.685g of ammonium persulfate in 20ml of water, and place in an ice bath for 10min; Add the solution dropwise to the aniline-tartaric acid solution under the condition of stirring in an ice bath, then put in carbon cloth (1*2cm), suspend the carbon cloth, keep the carbon cloth fully exposed in the aqueous solution, and stop stirring; place in the ice bath for 4~ After 48 hours, take out the carbon cloth electrode, and wash it repeatedly with deionized water and ethanol for 1 to 5 times. When cleaning, the ethanol can be replaced with methanol, acetone, benzene, petroleum ether, and ethyl acetate.

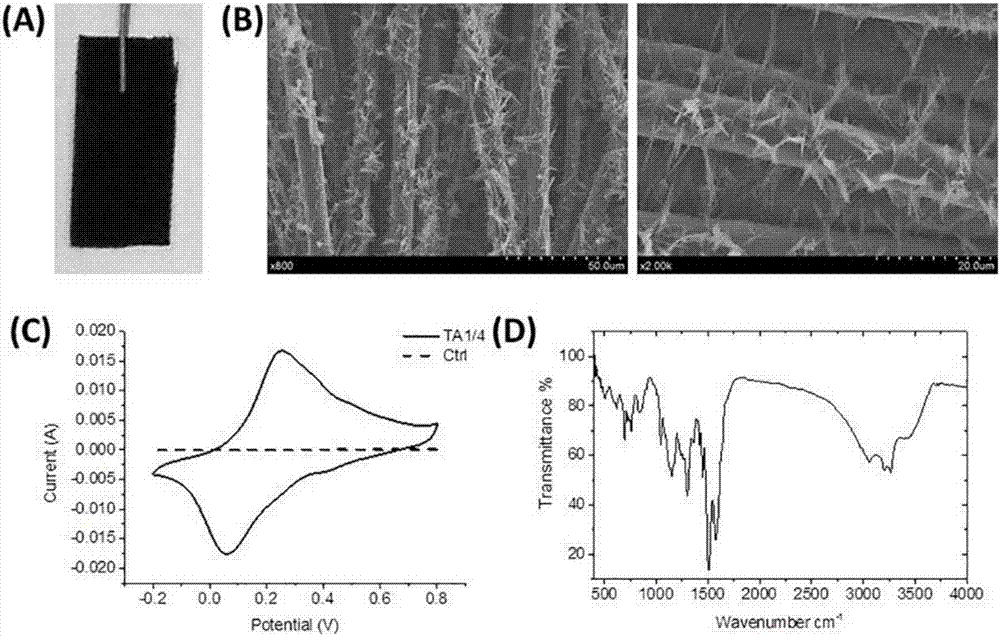

[0027] Such as figure 1 As shown, Figure A is the physical picture of the composite electrode; from the SEM image of Figure B, it can be seen that the surface of the ...

Embodiment 2

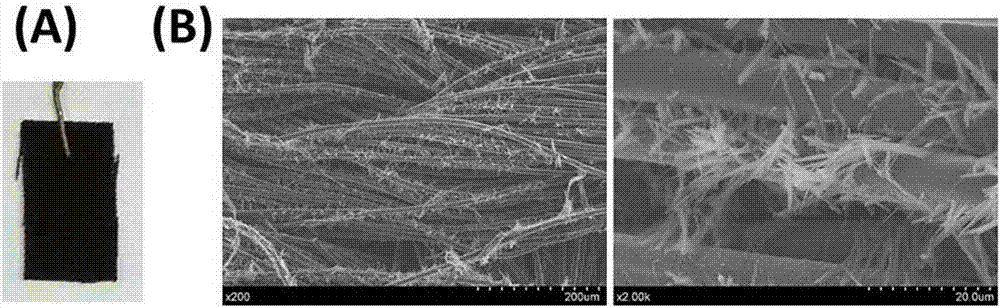

[0029] It is basically the same as Example 1, but following changes are arranged: the tartaric acid is 0.226g, and the appearance diagram and SEM scanning electron microscope picture of gained composite electrode are as figure 2 shown.

Embodiment 3

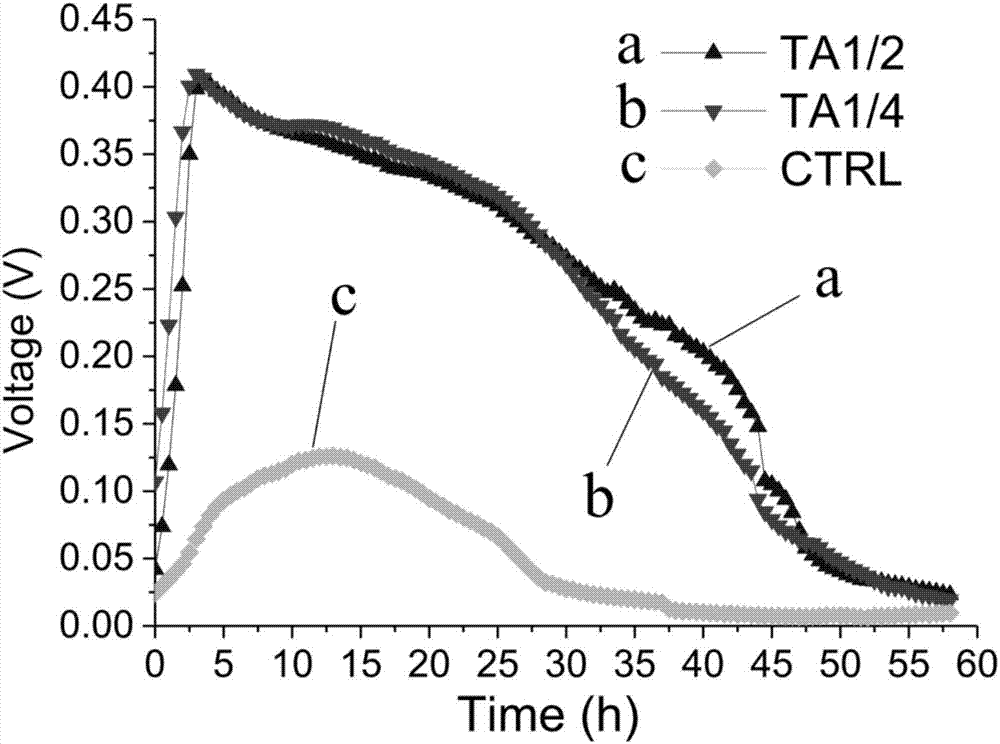

[0031] It is basically the same as Example 1, but following changes are arranged: the tartaric acid is 0.057g, and the gained composite electrode is applied to microbial fuel cells, and the maximum output voltage of the gained composite electrode reaches 373 millivolts, and the MFC of the common carbon cloth electrode of the control group prepared simultaneously The maximum output voltage is 126 millivolts, and the obtained composite electrode can improve the power generation performance of the microbial fuel cell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com