Method for in-situ modification of three-dimensional carbon microbial fuel cell by nanometer porous molybdenum carbide

An in-situ modification and nanoporous technology, applied in biochemical fuel cells, battery electrodes, circuits, etc., can solve the problem that the power generation capacity of microbial fuel cells has not been studied, reduce the activation overpotential of microbial anodes, and unfavorable implantation and growth of power-producing microorganisms and other problems, to achieve the effect of good microbial electrocatalytic ability, small interface charge transfer resistance, and high biocatalyst loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

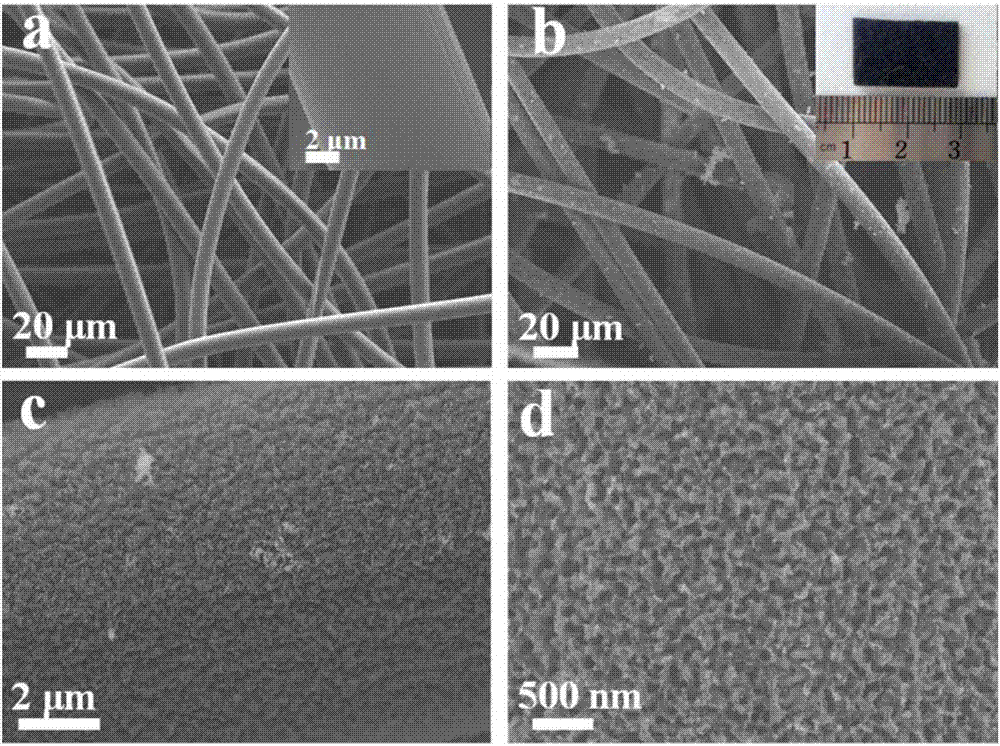

[0032] 1) Cut the carbon felt with a thickness of 3mm into small pieces of 1cm×2cm size, place it in 50mL acetone solution for ultrasonic cleaning for 1 hour, transfer it to 50mL 1M dilute hydrochloric acid for ultrasonic cleaning for 1 hour, transfer it to 100mL distilled water for ultrasonic cleaning Wash for 1 hour to remove surface impurities, then boil in 100mL distilled water for 30 minutes, dry for later use or as a reference electrode;

[0033] 2) Place the flaky carbon felt treated in step 1) in 50mL 10mg mL -1 Horizontally shake and react in polydiallyldimethylammonium chloride solution for 12 hours, take it out and wash it with distilled water for 3 times;

[0034] 3) Place the carbon felt obtained in step 2) in 50mL 20mg mL -1 In the phosphomolybdic acid solution, shake the reaction horizontally for 12 hours, take it out, wash it with distilled water for 3 times, and dry it for later use;

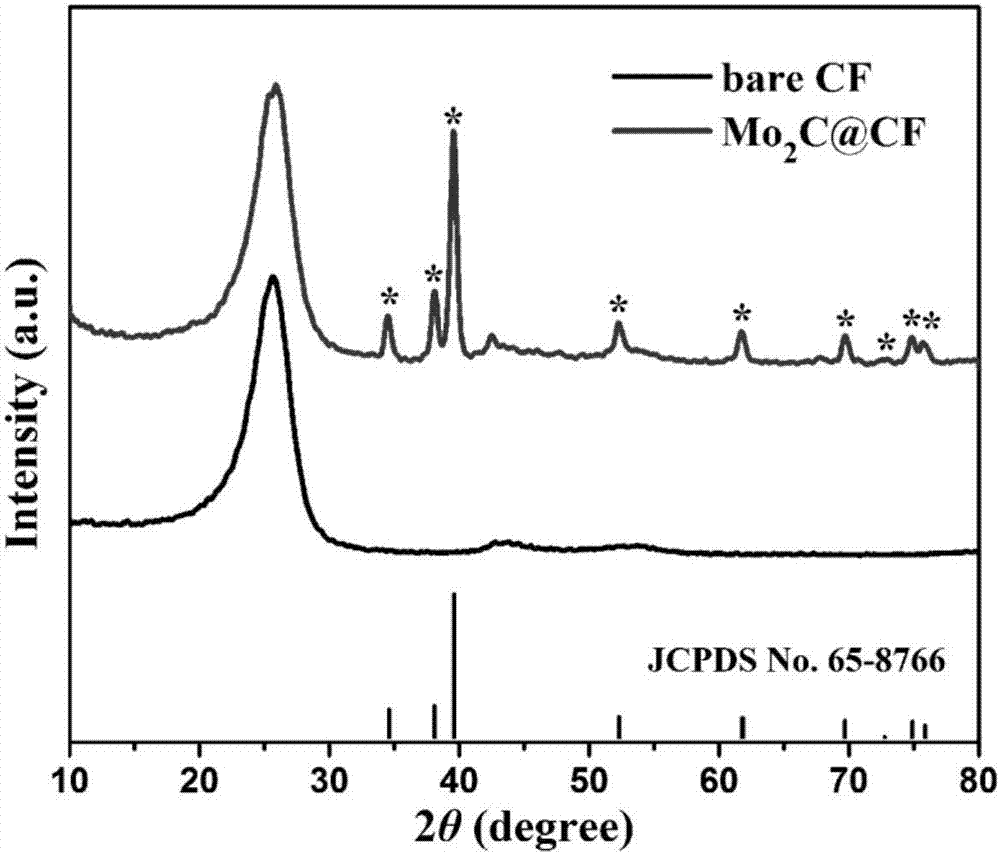

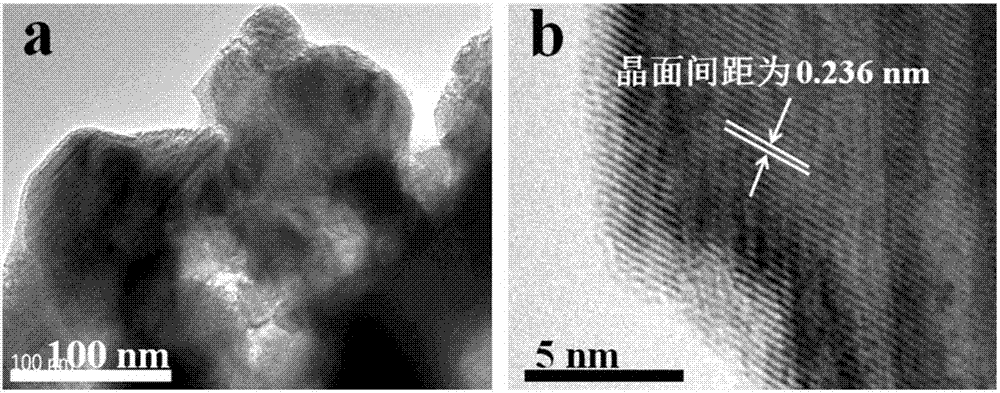

[0035] 4) Place the carbon felt obtained in step 3) in a vacuum tube furn...

Embodiment 2

[0038] The concentration of the phosphomolybdic acid solution of step 3) in embodiment 1 is adjusted to 10mg mL -1 , the other steps are the same as in Example 1, that is, a three-dimensional carbon felt electrode modified in situ with nanoporous molybdenum carbide with a molybdenum carbide loading of about 4.08wt% is obtained.

Embodiment 3

[0040] The concentration of the phosphomolybdic acid solution of step 3) in embodiment 1 is adjusted to 40mg mL -1 , the other steps were the same as in Example 1, that is, a three-dimensional carbon felt electrode modified in situ with nanoporous molybdenum carbide with a molybdenum carbide loading of about 12.36 wt % was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com