Anion-doped perovskite-type mixed conductor hydrogen permeable membrane material and its preparation method and application

A perovskite-type, mixed-conductor technology, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve the problem of reduced hydrogen flux in the total conductivity of zirconates, reduced material conductivity, high grain boundary resistance, etc. problems, to achieve the effect of increasing hydrogen permeation, increasing oxygen hole concentration, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A perovskite-type mixed conductor hydrogen permeable film material BaCe doped with fluorine ions in this embodiment 0.9 Fe 0.1 o 2.75-δ f 0.5 (BCFF 0.5 ) and perovskite-type hydrogen permeable membrane material BaCe without doped fluoride ions 0.9 Fe 0.1 o 3-δ The preparation method of (BCF9010), wherein δ=0~1, specifically comprises the following steps:

[0040] (1) Synthetic BCFF 0.5 : Weigh 25.65g BaCO respectively 3 , 16.41 g CeO 2 , 1.038g Fe 2 o 3 , 4.271gCeF 3 , add 20ml of ethanol after preliminary mixing, ball mill at a speed of 300r / min, take out and dry naturally after 5h;

[0041] (2) Synthesis of BCF9010: Weigh 25.65g BaCO respectively 3 , 20.14 g CeO 2 , 1.038g Fe 2 o 3 , add 20ml of ethanol after preliminary mixing, ball mill at a speed of 300r / min, take out and dry naturally after 5h;

[0042] (3) BCFF after ball milling 0.5 The raw material powder mixed evenly with BCF9010 was placed in a high-temperature muffle furnace and raised to 105...

Embodiment 2

[0046] A perovskite-type mixed conductor hydrogen-permeable membrane material SrCe not doped with anions in this embodiment 0.1 Zr 0.9 o 3-δ (SCZ) preparation method, wherein δ=0~1, specifically comprises the following steps:

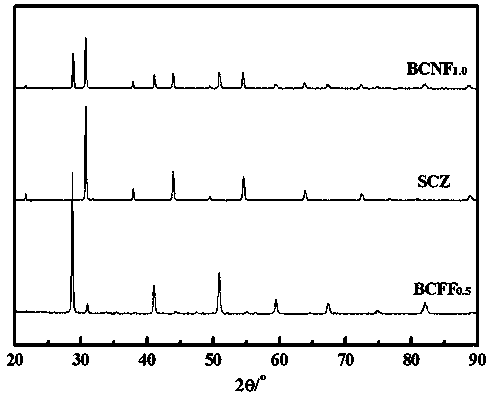

[0047] (1) Weigh 8.858g SrCO respectively 3 , 1.033g CeO 2 , 6.654g ZrO 2 , add 10ml of ethanol after preliminary mixing, ball mill at a speed of 300r / min, take it out and dry it naturally after 30h; then put it in a high-temperature muffle furnace to raise the temperature to 900°C at a heating rate of 1°C / min, keep it warm for 10h, and then The rate of 1°C / min was lowered to room temperature to obtain a phase-formed powder. The obtained SCZ powder is subjected to phase analysis, and the results are as follows: figure 1 shown.

[0048] (2) After a little grinding of the SCZ phase-formed powder, weigh 1g of the powder, place it in a stainless steel abrasive tool with an inner diameter of 16mm, and keep it under a pressure of 22.5MPa for 5min to ob...

Embodiment 3

[0050] A perovskite-type mixed conductor hydrogen permeable film material BaCe doped with fluorine ions in this embodiment 0.5 Ni 0.5 o 2.5-δ f 1.0 (BCFF 1.0 ) preparation method, wherein δ=0~1, specifically comprises the following steps:

[0051] (1) Weigh and weigh 29.60g BaCO respectively 3 , 8.606 g CeO 2 , 5.603g NiO 2 , 9.856g CeF 3 After preliminary mixing, 30ml of ethanol was added, ball milled at a speed of 300r / min, taken out and dried naturally after 17.5h; then placed in a high-temperature muffle furnace to raise the temperature to 1200°C at a heating rate of 2°C / min, and keep it warm for 10h, then Decrease to room temperature at a rate of 1°C / min to obtain a phase-formed powder. The obtained SCZ powder is subjected to phase analysis, and the results are as follows: figure 1 shown.

[0052] (2) BCFF 1.0 After a little grinding of the phase-formed powder, weigh 2g of the powder, put it in a stainless steel grinding tool with an inner diameter of 16mm, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com