Mining filling-closing material and preparation device thereof

A mining and fat technology, applied in the field of mining filling and sealing materials and preparation devices, can solve the problems of flammability, high reaction temperature and high price, and achieve the effects of light weight, excellent foam compression performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

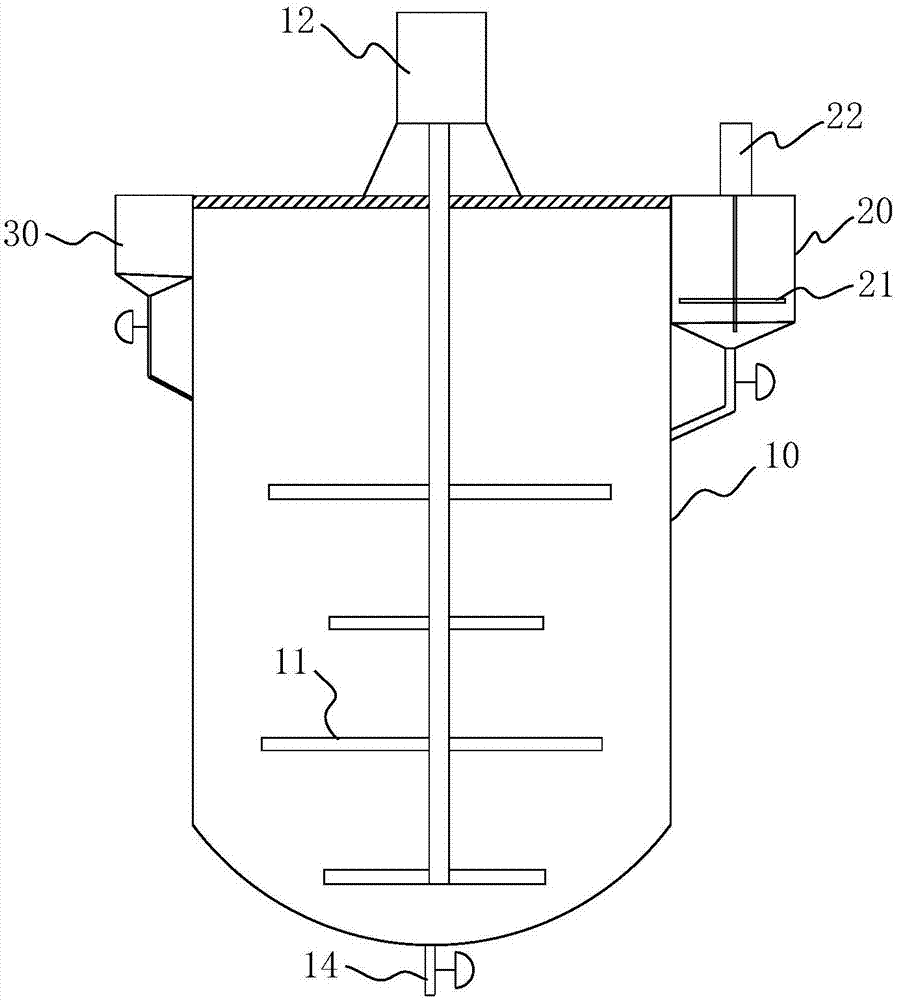

Image

Examples

Embodiment 1

[0019] Prepare materials according to the following weight composition: 100 parts of water, 45 parts of fly ash with a particle size range of 0.5 to 300 μm, 3 parts of gypsum, 10 parts of 42.5R cement, 12 parts of slaked lime, 1.2 parts of fatty alcohol polyoxyethylene ether, hydroxy 6.5 parts of ethyl methyl cellulose, 2 parts of sodium lauryl sulfate, 1 part of sodium fatty alcohol polyoxyethylene ether sulfate, 1.5 parts of polyphosphoric acid, 2 parts of hydroxypropyl starch ether with a viscosity of 300-600 mPas, acetic acid 1.2 parts of ethylene-ethylene copolymer redispersible latex powder, 12 parts of glass fiber with a length less than 2 mm, and enough silane coupling agent to impregnate the glass fiber.

[0020] The preparation steps are:

[0021] 1): Add 80 parts of water and all the fly ash, fatty alcohol polyoxyethylene ether, hydroxyethyl methylcellulose, gypsum, cement, slaked lime into the main mixing tank, and the agitator evenly forms the fly ash slurry, stir...

Embodiment 2

[0026] Prepare materials according to the following weight composition: 100 parts of water, 55 parts of fly ash with a particle size range of 0.5 to 300 μm, 1 part of gypsum, 15 parts of 42.5R cement, 10 parts of slaked lime, 1.8 parts of fatty alcohol polyoxyethylene ether, hydroxyl 8 parts of ethyl methyl cellulose, 2.5 parts of sodium lauryl sulfate, 1.2 parts of sodium fatty alcohol polyoxyethylene ether sulfate, 2 parts of polyphosphoric acid, 2.2 parts of hydroxypropyl starch ether with a viscosity of 300-600 mPas, acetic acid 1.2 parts of ethylene-ethylene copolymer redispersible latex powder, 10 parts of glass fiber with a length less than 2 mm and enough silane coupling agent to impregnate the glass fiber.

[0027] The preparation steps are:

[0028] 1): Add 80 parts of water and all the fly ash, fatty alcohol polyoxyethylene ether, hydroxyethyl methylcellulose, gypsum, cement, slaked lime into the main mixing tank, and the agitator evenly forms the fly ash slurry, st...

Embodiment 3

[0033] Prepare materials according to the following weight composition: 100 parts of water, 50 parts of fly ash with a particle size range of 0.5 to 300 μm, 2 parts of gypsum, 12 parts of 42.5R cement, 8 parts of slaked lime, 1.6 parts of fatty alcohol polyoxyethylene ether, hydroxy 7 parts of ethyl methyl cellulose, 2.4 parts of sodium lauryl sulfate, 1.4 parts of sodium fatty alcohol polyoxyethylene ether sulfate, 1.8 parts of polyphosphoric acid, 2.2 parts of hydroxypropyl starch ether with a viscosity of 300-600 mPas, acetic acid 1.5 parts of ethylene-ethylene copolymer type redispersible latex powder, 8 parts of glass fiber with a length less than 2mm and enough silane coupling agent to impregnate the glass fiber.

[0034] The preparation steps are:

[0035] 1): Add 82 parts of water and all the fly ash, fatty alcohol polyoxyethylene ether, hydroxyethyl methylcellulose, gypsum, cement, slaked lime into the main mixing tank, and the agitator evenly forms the fly ash slurry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com