A kind of white light fluorescent powder excited by ultraviolet LED and preparation method thereof

A fluorescent powder and white light technology, applied in the field of white light fluorescent powder, can solve the problems of poor thermal stability, low luminous efficiency of phosphors, inconsistent light decay, etc., and achieve short sintering time, high luminous intensity, good particle shape and uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) According to the chemical formula Sr 0.6 Ca 0.25 SM 0.04 Tb 0.06 T m 0.05 AlSiN 2.9 o 0.225 The stoichiometric ratio was weighed 0.02molSr 3 N 2 , 0.0083mol Ca 3 N 2 , 0.1mol AlN, 0.033mol Si 3 N 4 、0.002mol Sm 2 o 3 , 0.0015molTb 4 o 7 , 0.0025mol Tm 2 o 3 , the purity of the raw materials is 99.99%, and the particle size of the raw materials is 3-5 μm;

[0035] Note: All the above raw materials were weighed in the glove box N 2 Under the atmosphere

[0036] (2) Weighing by NH 4 Cl, NaF, H 3 BO 3 Composed mixed flux, the total mass of the mixed flux is 4% of the total mass of raw materials taken in step (1), and the mass ratio of the three is NH 4 Cl:NaF:H 3 BO 3 =2:3:2;

[0037] (3) All the raw materials and fluxes taken in steps (1) and (2) are placed in N 2Grind in an agate mortar for more than 40 minutes under the atmosphere to make it evenly mixed, then transfer the raw materials to the molybdenum crucible and cover the crucible lid, ...

Embodiment 2-11

[0045] The doping amounts of Sm, Tb, and Tm elements were changed (see Table 1 for details), and other process conditions were the same as in Example 1. The relevant test results obtained were compared with those of Example 1 and Comparative Example 1, as shown in Table 1.

[0046] Table 1:

[0047]

[0048]

[0049] It can be seen from Table 1 that the relative brightness of the embodiment of the present invention is obviously better than that of comparative example 1, and the color coordinates are closer to the pure white light color coordinates (0.33, 0.33).

[0050] Choose embodiment 1, embodiment 11 and comparative example 1 obtained fluorescent powder to carry out temperature quenching test, detection temperature rises to 500K from 300K, it is detected once every time the temperature changes by 50K, record results are shown in table 2, simultaneously The curves of the three samples with the change of temperature are drawn as follows: Figure 4 shown.

[0051] Tab...

Embodiment 12-19

[0059] Change the amount of addition of flux and change the ratio of each component in the flux (see Table 4 for details), other process conditions and raw material ratios are all the same as in Example 1, and the relevant test results obtained are compared with Example 1 and Comparative Example 1 , as shown in Table 4.

[0060] Table 4:

[0061]

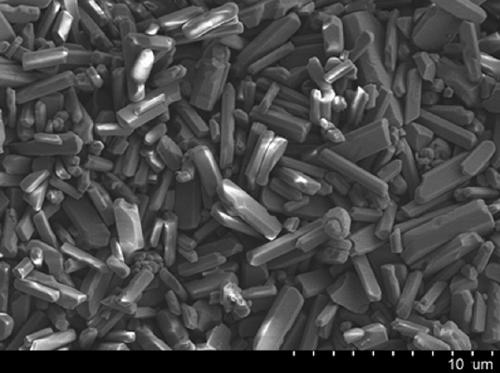

[0062] As can be seen from Table 4, the relative brightness of the fluorescent powder obtained in Comparative Example 1 is low, the particles are large, and need to be crushed, and the yield of the finished product is also low. It can be seen from Examples 12-13 and Examples 18-19 that a small amount or excessive amount of auxiliary powder is added. Flux makes the phosphor particles smaller or larger, which is not conducive to encapsulation, and the yield is not ideal; when the amount of flux added is 4%, NH 4 Cl:NaF:H 3 BO 3 When =2:3:2, the overall performance of the phosphor obtained is the best, and the phosphor powder pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com