Method for producing fuel ethanol by multi-strains co-fermentation of straws

A technology of fuel ethanol and fermentation bacteria, which is applied in the fields of fermentation engineering and biomass energy, and can solve problems such as strain degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

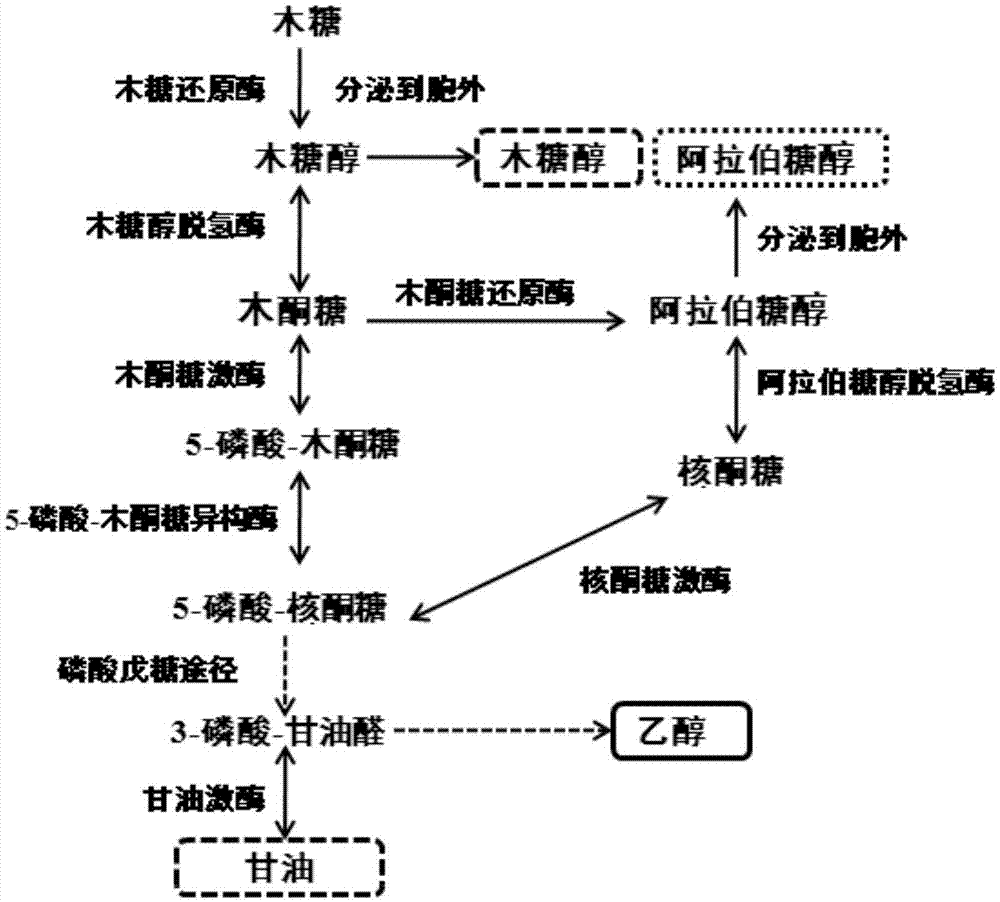

AI Technical Summary

Problems solved by technology

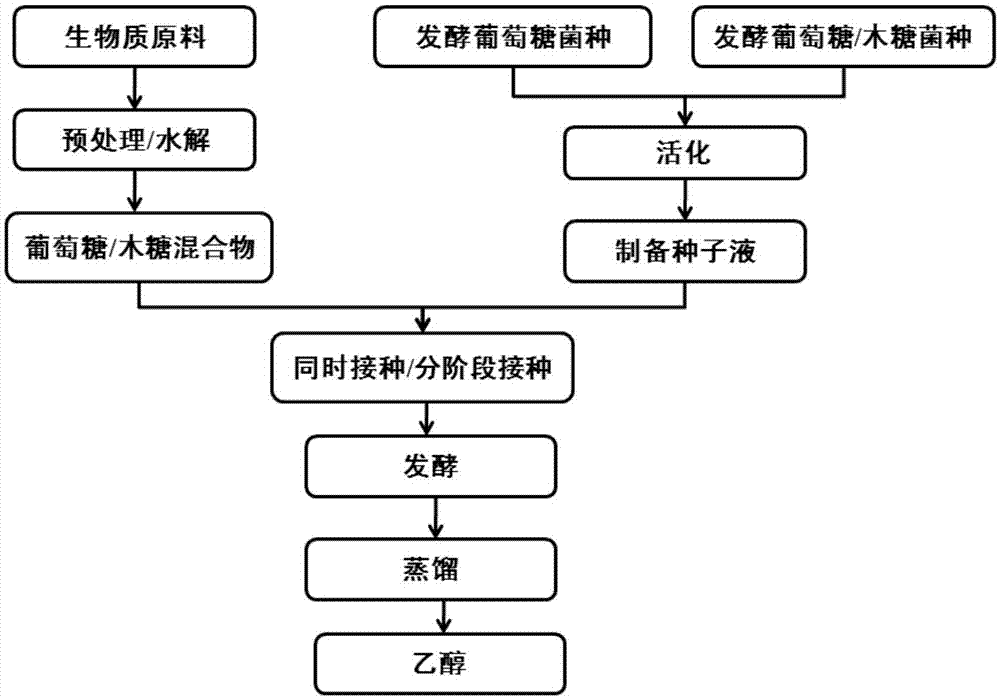

Method used

Image

Examples

Embodiment 1

[0069] Take commercially available glucose and xylose samples respectively, add water to mix glucose and xylose (the mass ratio of glucose and xylose is 4:1), wherein, the concentration of glucose is: 100g / L, and the concentration of xylose is: 25g / L L, add the yeast powder of 3g / L and other trace elements (the addition amount of other trace elements is: 1g / L potassium dihydrogen phosphate, 0.5g / L magnesium sulfate), obtain fermentation medium, sterilize for subsequent use.

[0070] Choose Zymomonas mobilis, inoculate to seed culture medium after activation (the formula of seed culture medium is: glucose 50g / L, KH 2 PO 4 2g / L, yeast powder 10g / L, pH7.0), after cultivating for 12h, the seed liquid of the bacterium was obtained.

[0071] Select Pachysolomyces tannophilus, inoculate it into the seed medium after activation (the formula of the seed medium is: glucose 20g / L, tryptone 3.0g / L, yeast extract 5.0g / L), after culturing for 48h, the obtained Bacteria seed fluid.

[00...

Embodiment 2

[0074] Crush corn stalks to a particle size of 20 mm, prepare the stalks to a concentration of 60 g / L, add commercially available cellulase such as Spezyme CP produced by Genenco and xylanase preparations such as Accellerase XC produced by Genenco, and the addition amounts are respectively 15U / g of straw was hydrolyzed for 48h at pH 7.0 and 50°C to prepare a mixture of glucose and xylose, and 2g / L of yeast powder and other trace elements were added (the amount of other trace elements: 3g / L potassium dihydrogen phosphate, 1g / L magnesium sulfate), obtain fermentation medium, sterilize for subsequent use.

[0075] Select Saccharomyces cerevisiae, inoculate to seed medium after activation (the formula of seed medium is: glucose 40g / L, KH 2 PO 4 3g / L, yeast powder 5g / L, pH7.0), after culturing for 18h, the seed liquid of the bacterium was obtained.

[0076] Select Candida shohata, inoculate into seed medium after activation (the formula of seed medium is: glucose 30g / L, trypton...

Embodiment 3

[0079] Crush the wheat straw to a particle size of 30mm, add 0.2mol / L H 2 SO 4 The solution is treated for 24 hours, the pretreated straw is washed with water until the pH is 6.0-7.0, and dried. Prepare the pretreated straw to a concentration of 70g / L, add commercially available cellulase such as Spezyme CP produced by Genencor or xylanase preparation such as Accellerase XC produced by Genencor, the addition amount is 10U / g straw, in pH 6.0, hydrolysis at 50°C for 48 hours to prepare a mixture of glucose and xylose, add 3g / L yeast powder and other trace elements (addition of other trace elements: 1g / L potassium dihydrogen phosphate, 0.5g / L L magnesium sulfate), to obtain the fermentation medium, sterilized for subsequent use.

[0080] Choose Kluyveromyces, inoculate to seed culture medium after activation (the prescription of seed culture medium is: glucose 50g / L, KH 2 PO 4 5g / L, yeast powder 10g / L, pH 7.0), after culturing for 24 hours, the seed liquid of the bacterium w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com