Silicon/lithium titanium dioxide ion battery negative electrode material and preparation method thereof

A lithium-ion battery and titanium dioxide technology, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc., can solve the problems of restricting large-scale industrial application of materials, high price of nano silicon powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

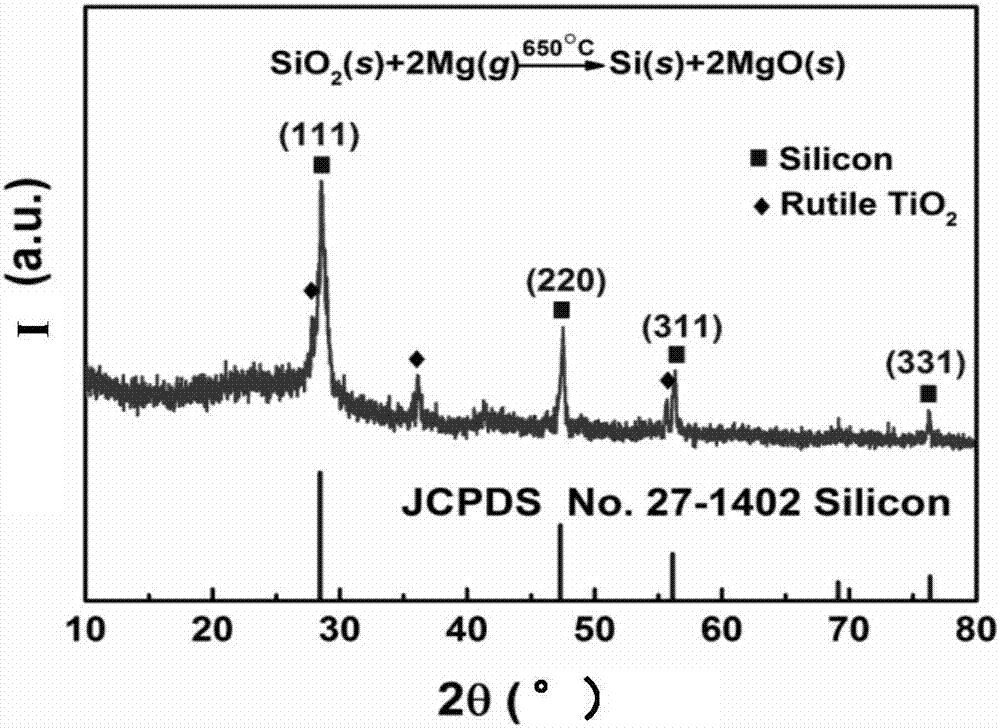

[0031] In one aspect of the present invention, the present invention proposes a method for preparing silicon / titanium dioxide lithium ion battery negative electrode material. refer to Figure 5 , the preparation method of the present invention is described in detail. According to an embodiment of the present invention, the preparation method includes:

[0032] S100: preparing SiO 2 hollow ball.

[0033] In this step, SiO can be prepared in advance 2 Hollow spheres, thus, can be used for subsequent coating of TiO on the surface 2 steps to use. According to the embodiment of the present invention, prepare SiO 2 The specific manner of the hollow sphere is not particularly limited, as long as the SiO 2 The hollow spheres can be used in subsequent coating and post-treatment steps, and those skilled in the art can choose according to actual needs. In some embodiments of the invention, SiO 2 Hollow spheres can be prepared by sol-gel method. Thus, using the above method can ...

Embodiment 1

[0057] In this example, a negative electrode material for a silicon / titanium dioxide lithium ion battery was prepared. The specific steps are as follows:

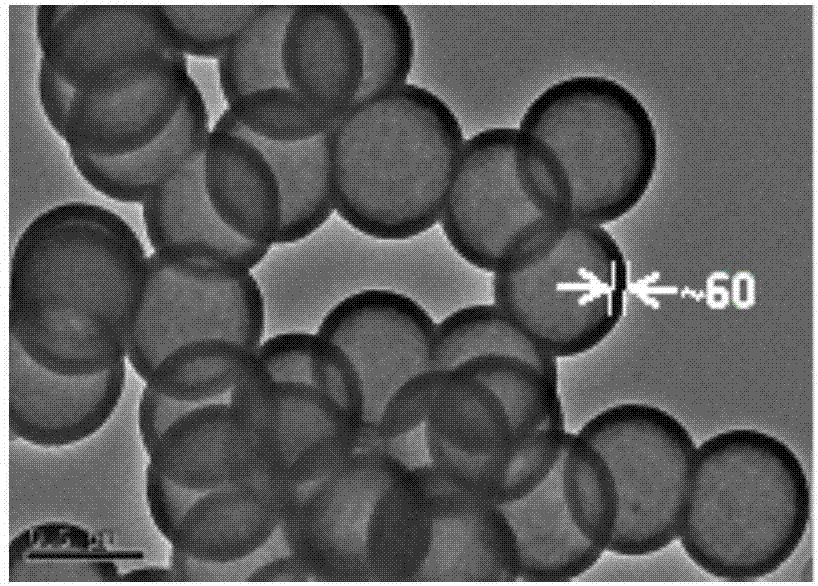

[0058] 1) SiO2 2 Preparation of hollow spheres: Prepare cetyltrimethylammonium bromide (CTAB), ethanol, ammonia water and water with a mass of 0.2g, 40g, 20g, and 100g to prepare a clear solution, then drop 2g of tetraethyl orthosilicate, Reacted for 12 hours; the reactants were centrifuged and washed 5 times, then redispersed in 200mL water, and placed at 70°C for 24 hours to obtain hollow SiO containing CTAB template 2 Then add it to a mixed solution of 150mL ethanol and 200μL hydrochloric acid with a concentration of 36.5v / v%, stir at 55°C for 3 hours, remove the CTAB contained in the material, and obtain hollow SiO with different wall thicknesses 2 ball.

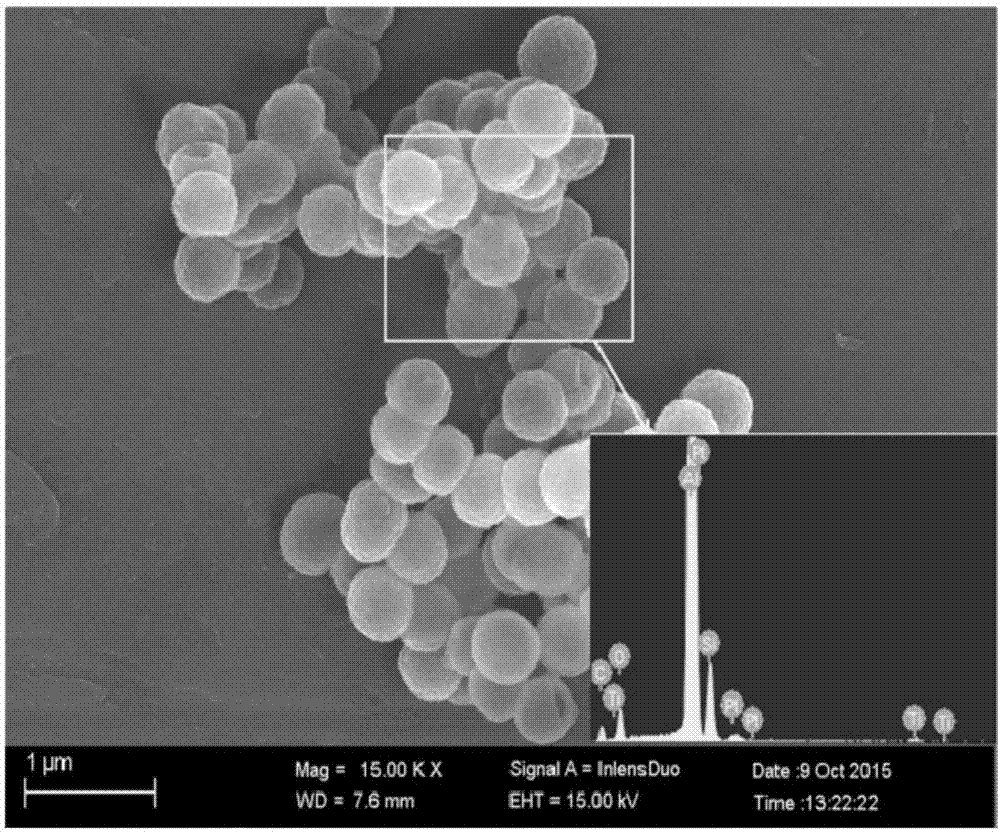

[0059] 2) TiO 2 coated SiO 2 Preparation of hollow spheres: the hollow SiO 2 The spheres were dispersed in a mixed solution of 50g ethanol and 1g water, and 0.5...

Embodiment 2

[0064] In this example, the silicon / titanium dioxide lithium ion battery negative electrode material was prepared according to the same method and conditions as in Example 1. The difference is that, in this embodiment, 1) cetyltrimethylammonium bromide (CTAB), ethanol, ammoniacal liquor and water are formulated into a clear solution with a quality of 0.3g, 50g, 25g, 100g, and then dropped into normal Ethyl silicate 3g, reacted for 24 hours; the reactant was redispersed in 400mL water after being centrifuged and washed 5 times, and placed at 80°C for 36 hours; In the mixed solution, stir at 60°C for 4 hours; 2) the hollow SiO 2 The spheres were dispersed in a mixed solution of 60g ethanol and 1.5g water, and 0.8g tetrabutyl titanate was added to react for 4 hours; 3) 1g hollow SiO 2 @TiO 2 The material was mixed with 1g of magnesium powder, heated to 750°C under an Ar atmosphere, and reacted for 4 hours; then the product was added to 1mol / L hydrochloric acid to react for 6 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com