Application of a chlorine-doped polymer-based composite material in cathode materials for chloride-ion batteries

A composite material, battery cathode technology, applied in battery electrodes, nanotechnology for materials and surface science, circuits, etc., can solve problems such as large volume changes of metal oxychloride, and achieve the effect of improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

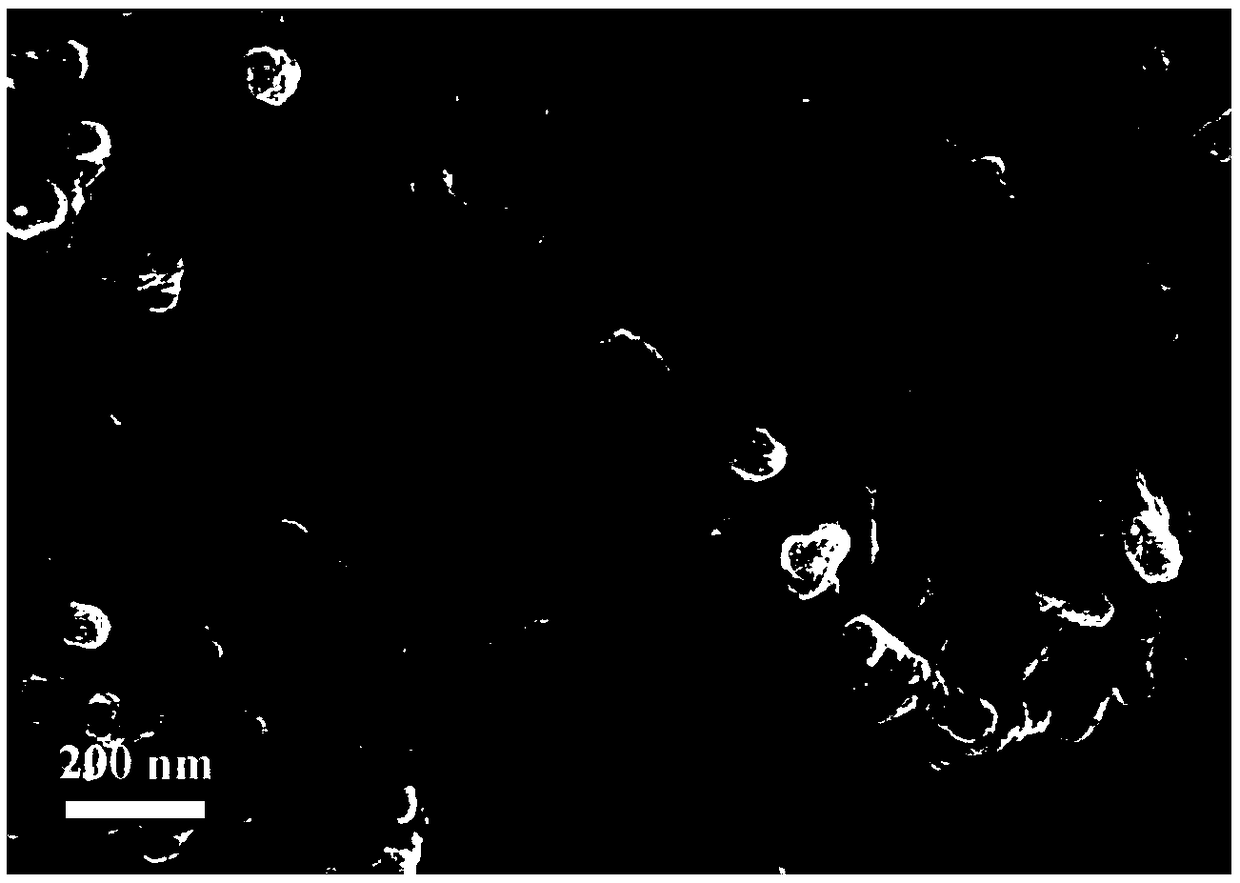

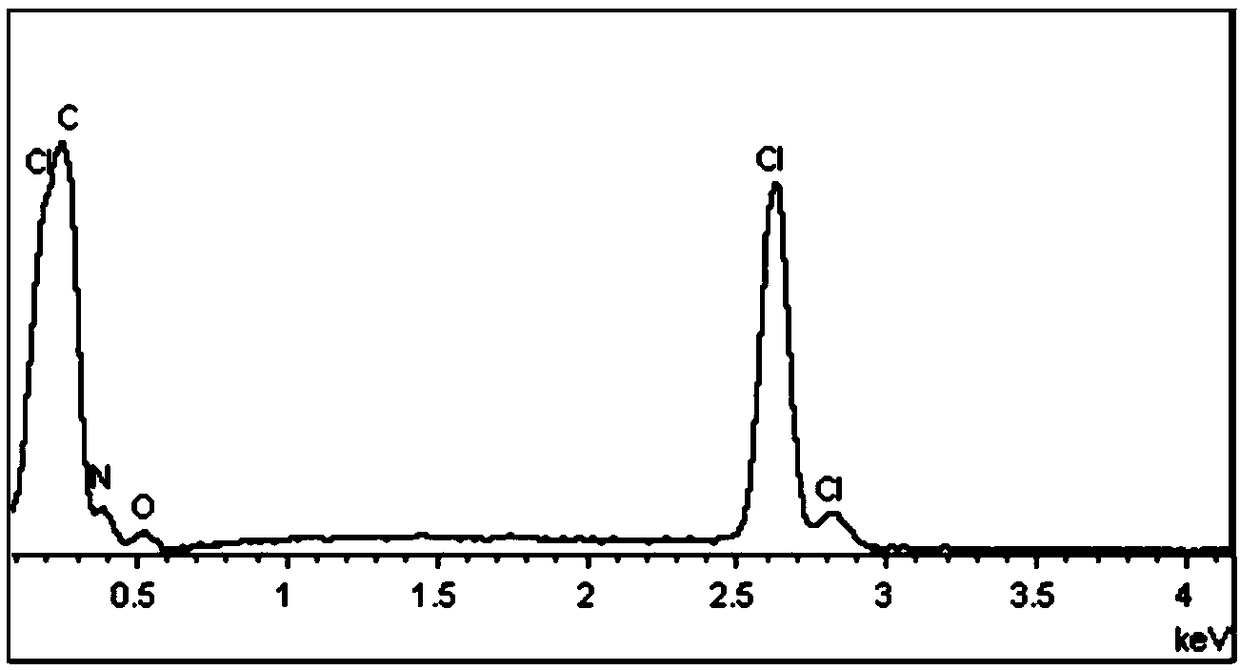

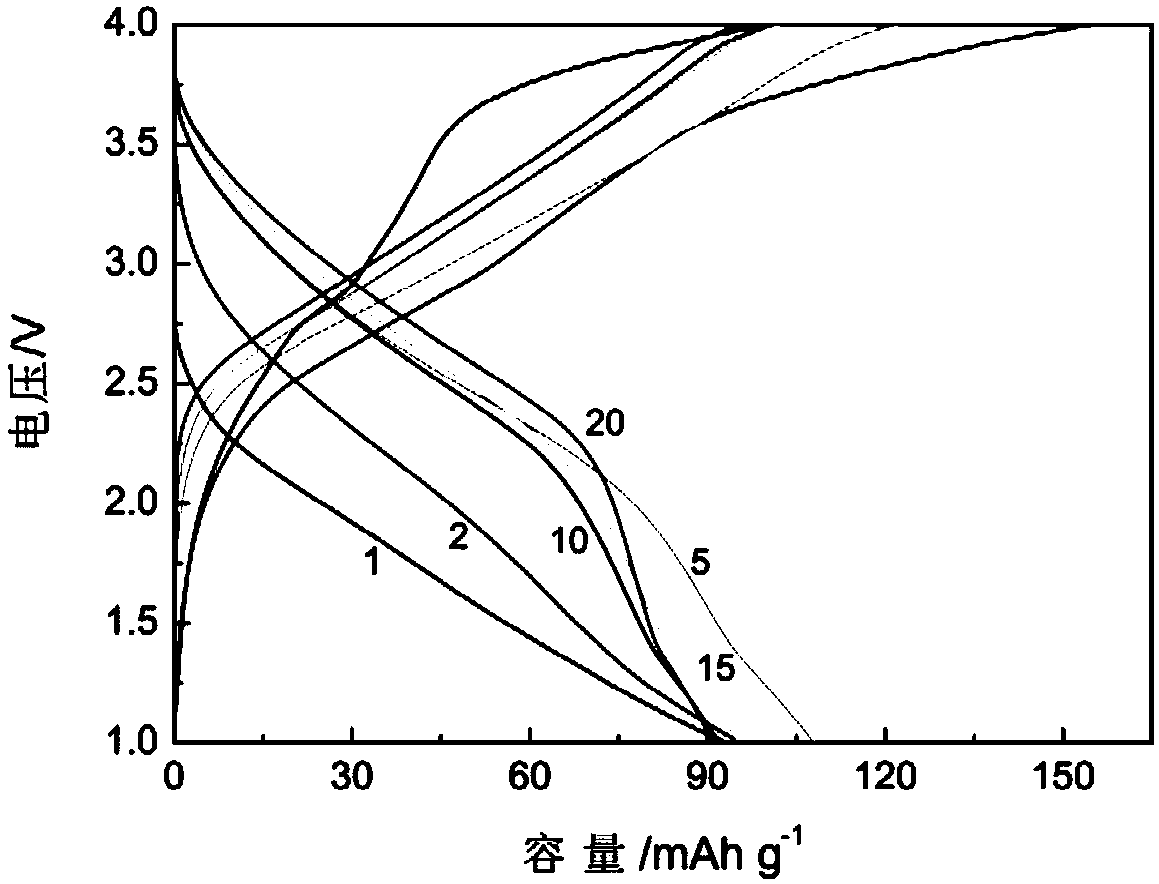

[0023] 1), material preparation and battery assembly: use pyrrole (0.42ml) as the monomer, carbon nanotubes as the carbon matrix, deionized water as the reaction medium, ferric chloride hexahydrate (50ml, 0.29M) as the oxidant and chlorine doped Miscellaneous agent, the molar ratio of ferric chloride hexahydrate and pyrrole monomer is 2.35:1; wherein the carbon nanotubes are oxidized by sulfuric acid / nitric acid. The chlorinated polypyrrole-based composite material (carbon nanotube content is 18%) was obtained by chemical reduction (reaction 4 hours), and this process was carried out under the protection of nitrogen atmosphere; the morphology is as follows figure 1 shown; figure 2 The energy spectrum results in , show the efficient doping of chlorine element in the polymer composite. The composite material is mixed with acetylene black and PTFE, and then coated on a stainless steel mesh, and then cold-pressed to make a positive electrode; the negative electrode material is L...

Embodiment 2

[0027] 1), material preparation and battery assembly: use pyrrole (0.42ml) as monomer, ferric chloride hexahydrate (50ml, 0.49M) as oxidant and chlorine dopant, deionized water as reaction medium, trichloride hexahydrate The molar ratio of iron oxide and pyrrole monomer is 4:1, and polypyrrole chloride is obtained by chemical reduction (10 hours of reaction), and this process is carried out under the protection of argon atmosphere; C, N, H element analysis shows that the The C:N:H of the prepared polypyrrole is 3.98:1:3.04, which is very close to the theoretical composition. Mix polypyrrole with acetylene black and PTFE, apply it on stainless steel mesh, and then cold press it to make a positive electrode; the negative electrode material is Li, and the electrolyte is 0.5MPP 14 Cl / PP 14 TFSI mixed ionic liquid.

[0028] 2) The results of charge and discharge experiments show that the first discharge capacity of the polypyrrole positive electrode material is 105mAh / g. After 3...

Embodiment 3

[0030] 1), material preparation and battery assembly: use thiophene (0.4ml) as a monomer, carbon nanotubes as a carbon matrix, ferric chloride hexahydrate (50ml, 0.3M) as an oxidant and a chlorine dopant, and deionized water as In the reaction medium, the molar ratio of ferric chloride hexahydrate and pyrrole monomer is 3:1; wherein the carbon nanotubes are oxidized by sulfuric acid / nitric acid. The chlorinated polythiophene-based composite material (carbon nanotube content is 35%) was obtained by chemical reduction (reaction 6 hours), and this process was carried out under the protection of a nitrogen atmosphere; the composite material was mixed with acetylene black and PTFE and then coated with onto a stainless steel mesh, and then cold-pressed to make a positive electrode; the negative electrode material is Li, and the electrolyte is 0.5M PP 14 Cl / PP 14 TFSI mixed ionic liquid.

[0031] 2) The results of charge and discharge experiments show that the first discharge capac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com