A thermal energy storage system and its preparation method

A thermal energy storage and phase change material technology, applied in the field of rubber, can solve the problems of reducing the efficiency of phase change material storage and release energy, etc., and achieve the effect of preventing liquid seepage, simple process and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] An embodiment of the present invention provides a method for preparing a thermal energy storage system, comprising the following steps:

[0037] Step 1: mixing the rubber with a compounding agent to obtain a compounded rubber, the compounding agent including an acrylate, a vulcanizing agent and an anti-aging agent;

[0038] In the embodiment of the present invention, one or more combinations of the preferred saturated natural rubber, ethylene-propylene rubber, butadiene rubber and styrene-butadiene rubber of the rubber; the preferred dicumyl peroxide and 2, One or two combinations of 5-dimethyl-2,5-bis(tert-butylperoxy)hexane; the anti-aging agent is one of the amine and phenolic anti-aging agents suitable for rubber systems One or more than one combination, the amine antioxidant such as N-phenyl-β-naphthylamine, N-octyl-N'-phenyl-p-phenylenediamine, 2,2,4-trimethyl-1 , 2-dihydroquinoline polymer, 3-hydroxybutyraldehyde-α-naphthylamine, N,N'-di-o-tolylethylenediamine, ...

Embodiment 1

[0061] (1) Weigh 100g of EPDM rubber, 30g of sodium methacrylate, 0.75g of dicumyl peroxide, 5g of fumed silica, 1g of antioxidant D (N-phenyl-β-naphthylamine), organic Foaming agent OT 5g, sodium bicarbonate 3g, stearic acid 3g.

[0062] (2) Plasticize the rubber, then place it at room temperature, add fumed white carbon black, sodium methacrylate, antioxidant D, organic foaming agent OT, sodium bicarbonate, stearic acid and diisophenyl peroxide in sequence according to the formula C, carry out mixing on the open mill, after thin pass several times, take out sheet, obtain mixing film;

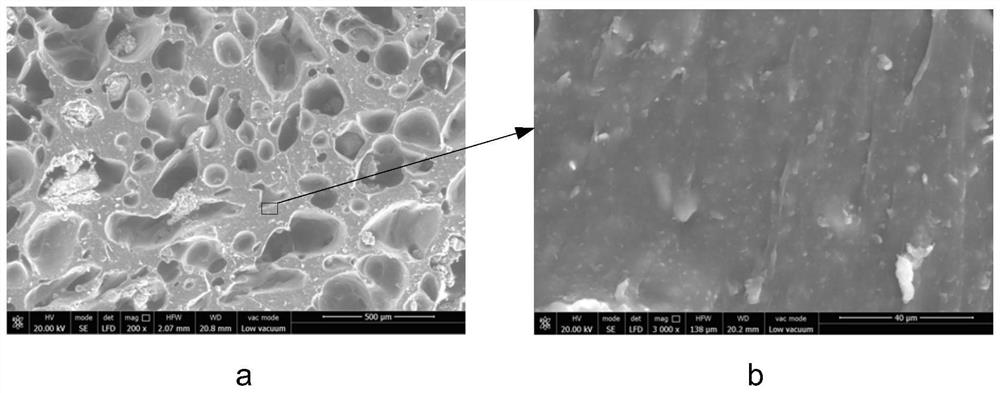

[0063] (3) Divide the mixed rubber sheet into two-stage molding vulcanization, the mold clamping pressure is 0.3MPa, the first-stage vulcanization temperature is 110°C, and the vulcanization time is 15 minutes, and then quickly transferred to the second-stage vulcanization, the vulcanization temperature is 170°C, and the vulcanization time is 15 minutes. The sample size is 2cm×2cm×0.2cm. SEM...

Embodiment 2

[0066] (1) Weigh 100 g of EPDM rubber, 30 g of sodium methacrylate, 0.75 g of dicumyl peroxide, and 1 g of antiaging agent D (N-phenyl-β-naphthylamine).

[0067] (2) Plasticize the rubber, then place it at room temperature, add sodium methacrylate, anti-aging agent D and dicumyl peroxide in sequence according to the formula, knead it on an open mill, thin it several times, and then release the sheet. Obtain mixed film;

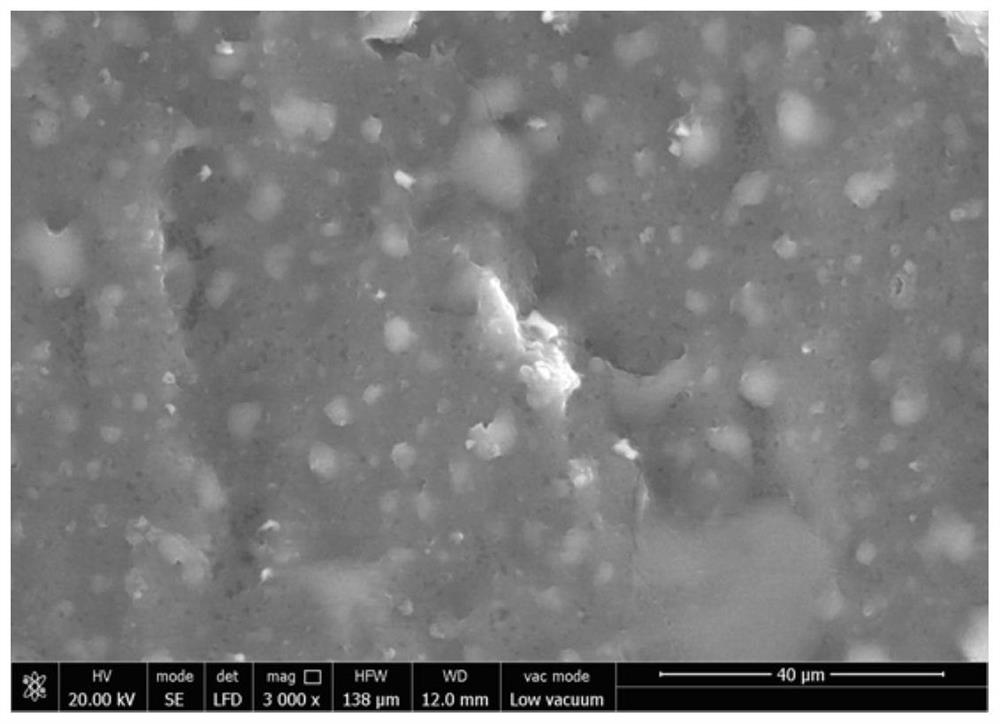

[0068] (3) The mixed rubber sheet is molded and vulcanized, the clamping pressure is 0.3MPa, the vulcanization temperature is 160°C, and the vulcanization time is 30min. The sample size is 2cm×2cm×0.2cm. The SEM image of the molded vulcanized rubber is attached figure 2 , obviously formed a two-phase structure: rubber phase and sodium methacrylate phase.

[0069] (4) Soak the vulcanized rubber pressed in step (3) in water at 40°C for 7 days until the weight of the rubber does not change; place the vulcanized rubber saturated with water in 50°C n-hexadecane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com