Method for low temperature rapid welding between ceramic or ceramic-based composite material and metal

A composite material, rapid welding technology, applied in the field of low temperature rapid welding between ceramic or ceramic matrix composite materials and metal, can solve the problems of small current/voltage, not reaching the critical value, long time, etc., to improve welding speed, reduce effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

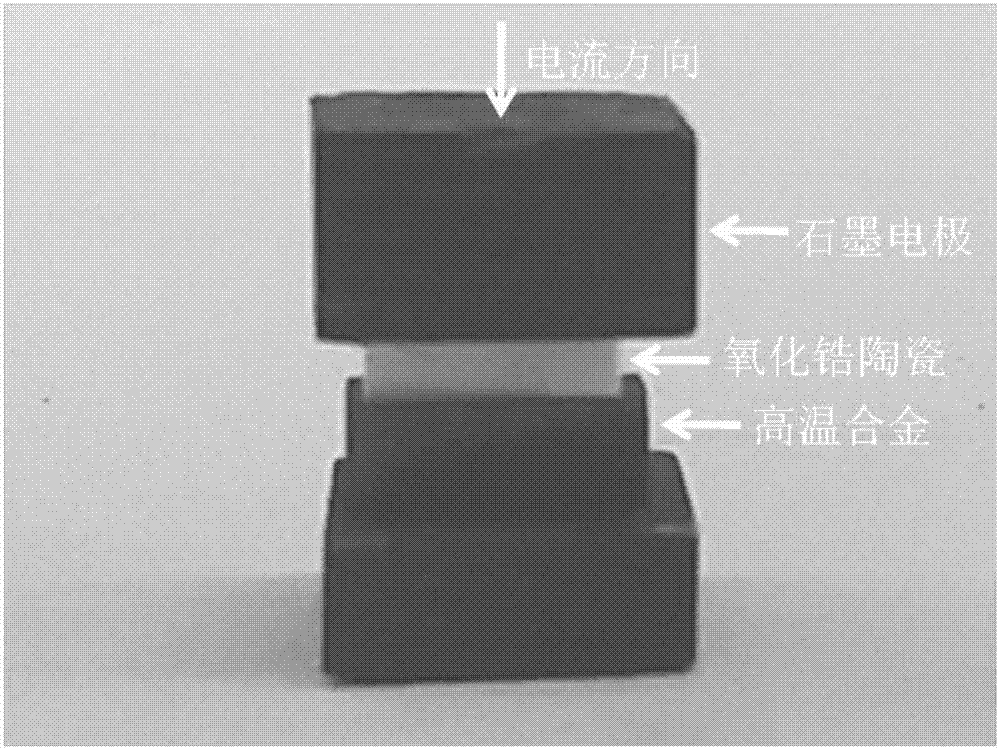

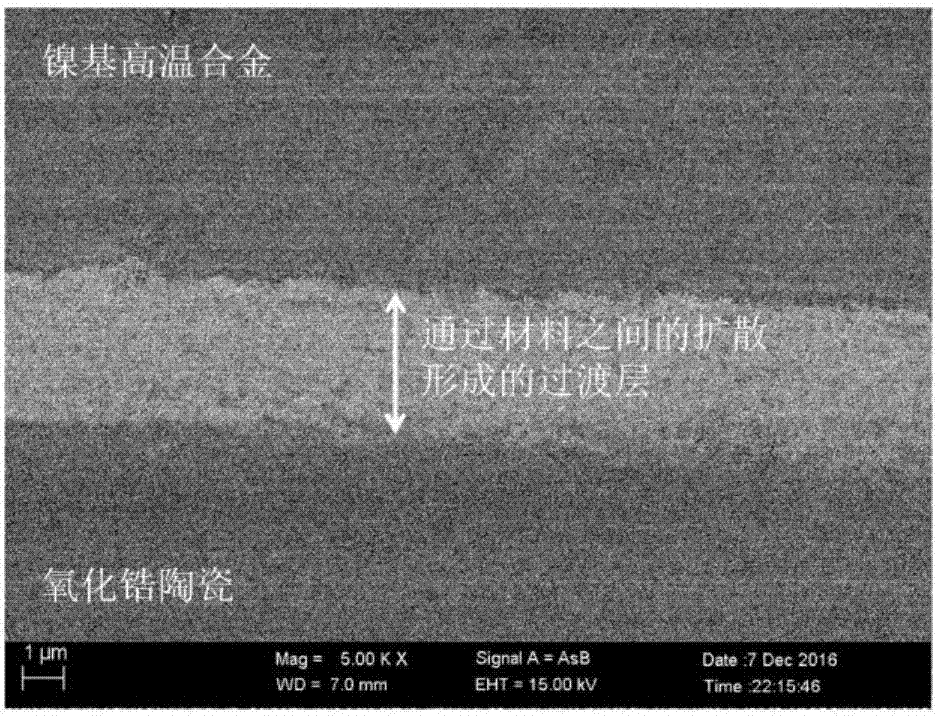

[0021] a) Polish the surface of sintered dense zirconia ceramics and nickel-based metal GH710 samples to 3 μm;

[0022] b) Put the surface of the sample obtained in step a) close together, apply 5MPa pressure;

[0023] c) heating the sample obtained in step b) to 700℃ ;

[0024] d) Apply to the sample obtained in step c) The current density is 350mA / mm 2 and keep it for 1min , so that the diffusion welding between the samples.

Embodiment 2

[0026] a) Polish the surface of sintered dense zirconia ceramics and nickel-based metal GH3044 samples to 1 μm;

[0027] b) Put the surface of the sample obtained in step a) close together, apply 1MPa pressure;

[0028] c) heating the sample obtained in step b) to 900℃;

[0029] d) Apply to the sample obtained in step c) The current density is 50mA / mm 2 and hold for 5s , so that the diffusion welding between the samples.

Embodiment 3

[0031] a) Polish the surface of sintered dense zirconia ceramics and cobalt-based metal GH5188 samples to 1 μm;

[0032] b) Put the surface of the sample obtained in step a) close together, apply 5MPa pressure;

[0033] c) heating the sample obtained in step b) to 500℃ ;

[0034] d) Apply to the sample obtained in step c) The current density is 450mA / mm 2 and keep for 5min , so that the diffusion welding between the samples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com