Laundry sheet and preparation method thereof

A technology of laundry tablets and polyvinyl alcohol, which is applied in chemical instruments and methods, detergent powder/sheet/sheet, detergent materials, etc., can solve the problem of unscientific way of adding enzymes, and the decontamination ability of laundry tablets is difficult to reach the national level. Standard and effective decontamination ingredients with low content of active substances, to achieve the effect of strong decontamination and descaling ability, fast dissolving speed and mild hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

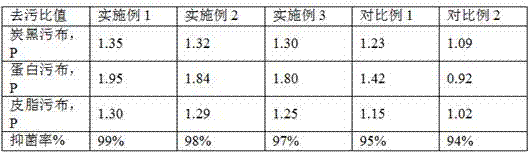

Examples

Embodiment 1

[0029] A laundry tablet, consisting of the following ingredients in parts by weight: 7 parts of polyvinyl alcohol, 3 parts of cross-linked sodium hydroxymethyl starch, 2 parts of cross-linked polyvinylpyrrolidone, 3 parts of sucrose ester, cocoyl isethionic acid Sodium 4 parts, Laureth 4 parts, Cocamidopropyl dimethyl betaine 1 part, Lauryl dimethyl sulfopropyl betaine 5 parts, Chitosan 3 parts, Malic acid 4 parts 3 parts of acrylic acid-2-acrylamide-2-methylpropanesulfonic acid-hydroxypropyl acrylate terpolymer, 3 parts of dipotassium glycyrrhizinate, 2 parts of MA5-DETA, 3 parts of decanoyl acetaldehyde, methylnonyl 3 parts of ketone lauric acid, 5 parts of orange peel extract, 6 parts of pomegranate peel extract, 1.5 parts of bamboo vinegar, 2 parts of sodium chloride, 6 parts of polyol, 2 parts of enzyme, 35 parts of deionized water. The average molecular weight of the acrylic acid-2-acrylamide-2-methylpropanesulfonic acid-hydroxypropyl acrylate terpolymer is 3500. The en...

Embodiment 2

[0043] A laundry tablet, consisting of the following components by weight: 6 parts of polyvinyl alcohol, 3 parts of cross-linked sodium hydroxymethyl starch, 2 parts of cross-linked polyvinylpyrrolidone, 1 part of sucrose ester, cocoyl isethionic acid Sodium 3 parts, Laureth 3 parts, Cocamidopropyl dimethyl betaine 1 part, Lauryl dimethyl sulfopropyl betaine 1 part, Chitosan 1 part, Malic acid 2 parts Acrylic acid-2-acrylamide-2-methylpropanesulfonic acid-hydroxypropyl acrylate terpolymer 1 part, dipotassium glycyrrhizinate 2 parts, MA5-DETA 1 part, decanoyl acetaldehyde 2 parts, methylnonyl 2 parts of ketone lauric acid, 3 parts of orange peel extract, 5 parts of pomegranate peel extract, 1 part of bamboo vinegar, 1 part of sodium chloride, 3 parts of polyol, 2 parts of enzyme, 30 parts of deionized water. The average molecular weight of the acrylic acid-2-acrylamide-2-methylpropanesulfonic acid-hydroxypropyl acrylate terpolymer is 3500. The enzyme is made by mixing amylase,...

Embodiment 3

[0046] A laundry tablet, consisting of the following components by weight: 8 parts of polyvinyl alcohol, 5 parts of cross-linked sodium hydroxymethyl starch, 3 parts of cross-linked polyvinylpyrrolidone, 5 parts of sucrose ester, cocoyl isethionic acid Sodium 5 parts, Laureth 5 parts, Cocamidopropyl dimethyl betaine 2 parts, Lauryl dimethyl sulfopropyl betaine 5 parts, Chitosan 3 parts, Malic acid 5 parts Parts, 3 parts of acrylic acid-2-acrylamide-2-methylpropanesulfonic acid-hydroxypropyl acrylate terpolymer, 5 parts of dipotassium glycyrrhizinate, 1-2 parts of MA5-DETA, 3 parts of decanoyl acetaldehyde, formaldehyde 3 parts of nonyl ketone lauric acid, 8 parts of orange peel extract, 10 parts of pomegranate peel extract, 2 parts of bamboo vinegar, 3 parts of sodium chloride, 8 parts of polyol, 4 parts of enzyme, 40 parts of deionized water.

[0047] The average molecular weight of the acrylic acid-2-acrylamide-2-methylpropanesulfonic acid-hydroxypropyl acrylate terpolymer i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com