Intercalated zinc-aluminum alloy powder and its prepared zinc-aluminum synergistic anticorrosion coating and method

A zinc-aluminum alloy, anti-corrosion coating technology, applied in anti-corrosion coatings, conductive coatings, polyurea/polyurethane coatings, etc., can solve the problem of difficult to achieve zinc-aluminum synergistic anti-corrosion effect, difficult to ensure dry coating density, no zinc metallic luster and other problems, to achieve the effect of solving the problem of zinc-aluminum synergistic anti-corrosion, controllable product thickness, environment and operator friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

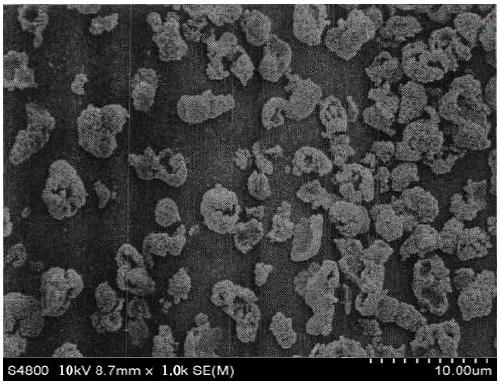

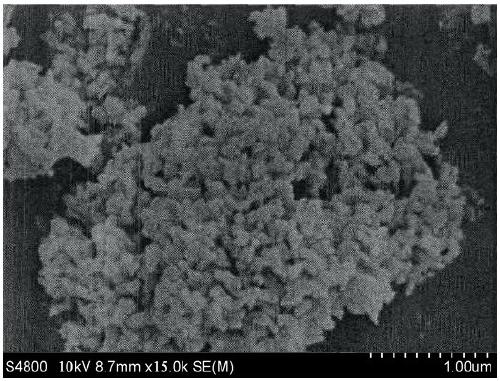

Image

Examples

reference example 1

[0039] The preparation method of zinc chloride molten salt electrolyte is: stir 90 parts of formamide, 120 parts of carbonamide and 480 parts of anhydrous zinc chloride at a speed of 600r / min to prepare; The molar ratio of zinc chloride hydrate is 1.13:1.

[0040] The preparation method of aluminum chloride molten salt electrolyte is: according to parts by weight, 90 parts of formamide, 120 parts of carbonamide and 399 parts of anhydrous aluminum chloride are stirred evenly at a speed of 600r / min, and the amide The mol ratio of compound and anhydrous aluminum chloride is 1.34:1.

reference example 2

[0042] The preparation method of the zinc chloride molten salt electrolyte is as follows: in parts by weight, 90 parts of formamide, 146 parts of propionamide and 480 parts of anhydrous zinc chloride are evenly stirred at a speed of 500 r / min to form; the amide The molar ratio of compound and anhydrous zinc chloride is 1.13:1.

[0043] The preparation method of aluminum chloride molten salt electrolyte is as follows: according to parts by weight, 90 parts of formamide, 146 parts of propionamide and 390 parts of anhydrous aluminum chloride are stirred evenly at a speed of 500 r / min, and the amide The molar ratio of compound and anhydrous aluminum chloride is 1.37:1.

reference example 3

[0045] The preparation method of zinc chloride molten salt electrolyte is: by weight, 146 parts of propionamide, 120 parts of carbonamide and 480 parts of anhydrous zinc chloride are stirred evenly at a speed of 700r / min, and the amide The molar ratio of compound and anhydrous zinc chloride is 1.13:1.

[0046] The preparation method of aluminum chloride molten salt electrolyte is as follows: by weight, 146 parts of propionamide, 120 parts of carbonamide and 390 parts of anhydrous aluminum chloride are stirred evenly at a speed of 700r / min, and the amide The molar ratio of compound and anhydrous aluminum chloride is 1.37:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com