Sodium ion secondary battery and non-aqueous electrolyte therefor

A non-aqueous electrolyte, secondary battery technology, applied in the field of materials, can solve the problems of corrosion current generation, narrow electrochemical window, limited application, etc., to achieve the effect of improving working voltage, inhibiting corrosion, improving performance and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The present embodiment prepares non-aqueous electrolyte according to the following steps:

[0034] At room temperature, in a glove box, mix dimethyl carbonate and ethylene carbonate solvents, then add sodium bisfluorosulfonyl imide, then add functional additives, and stir evenly to obtain a non-aqueous electrolyte.

[0035] Through the above steps, 9 kinds of non-aqueous electrolyte solutions 1-9 in Table 1 were prepared by using different contents of different functional additives.

[0036] Table 1. Components and various contents of non-aqueous electrolytes.

[0037]

Embodiment 2

[0039] The positive electrode is made of aluminum foil cut to a diameter of 14 mm, and the negative electrode is made of a metal sodium sheet with a diameter of 10 mm. The electrolytes 1-9 prepared in Example 1 and the control electrolyte are respectively added to assemble button-type secondary batteries 1A-1I and control 2 Secondary battery 1.

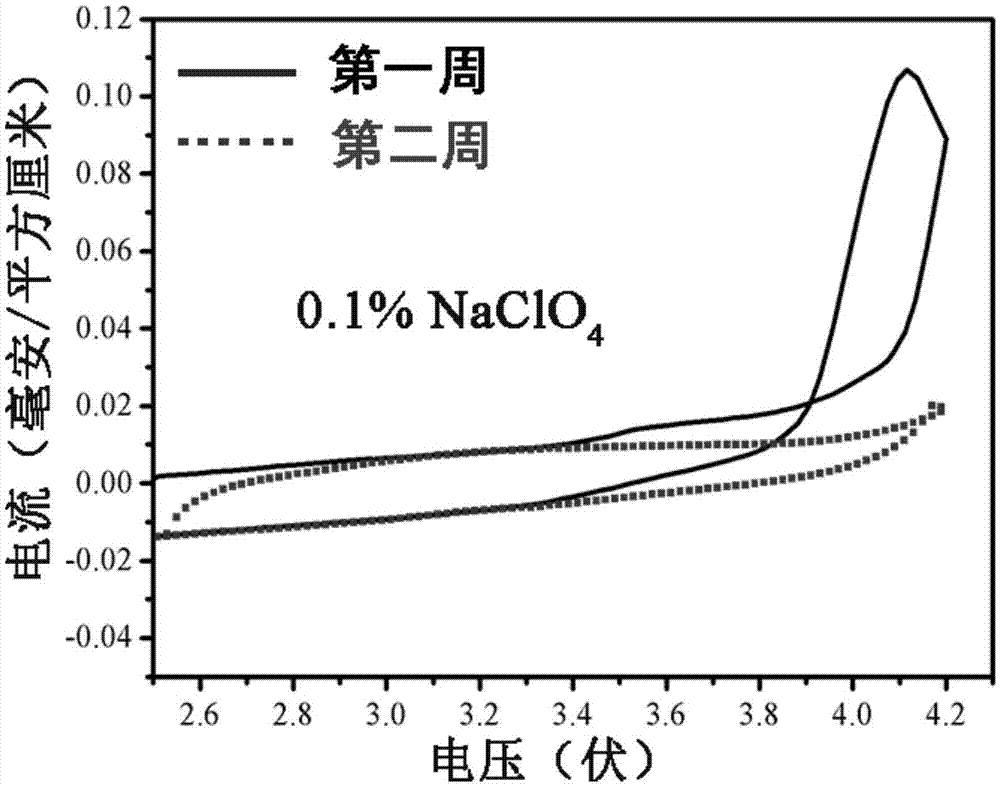

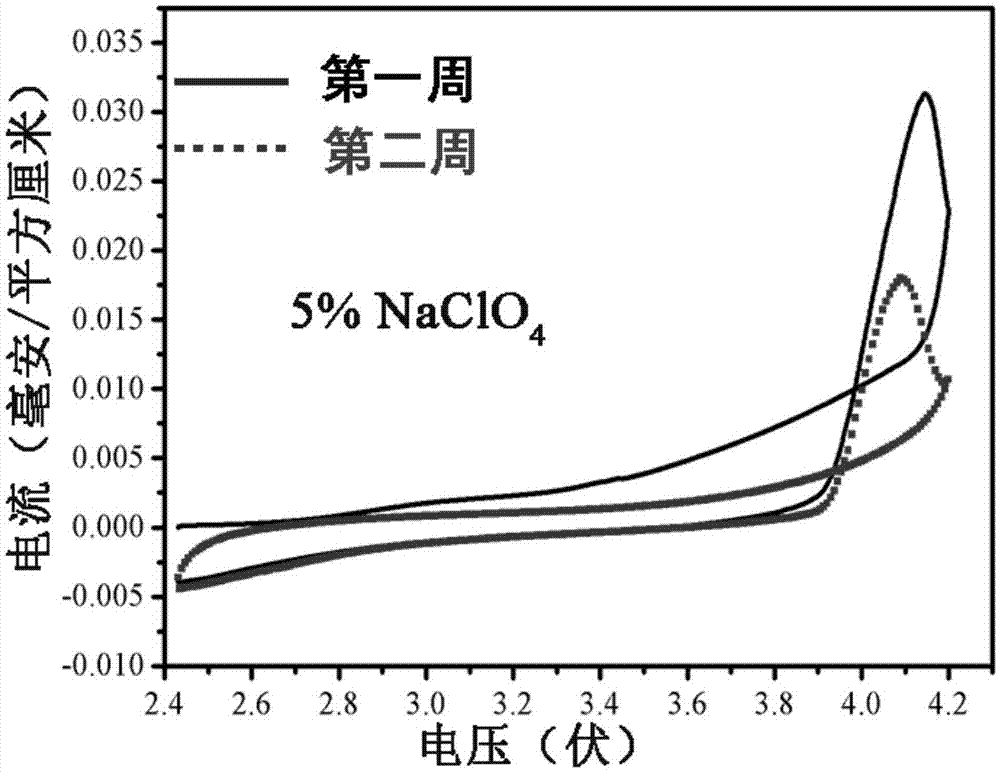

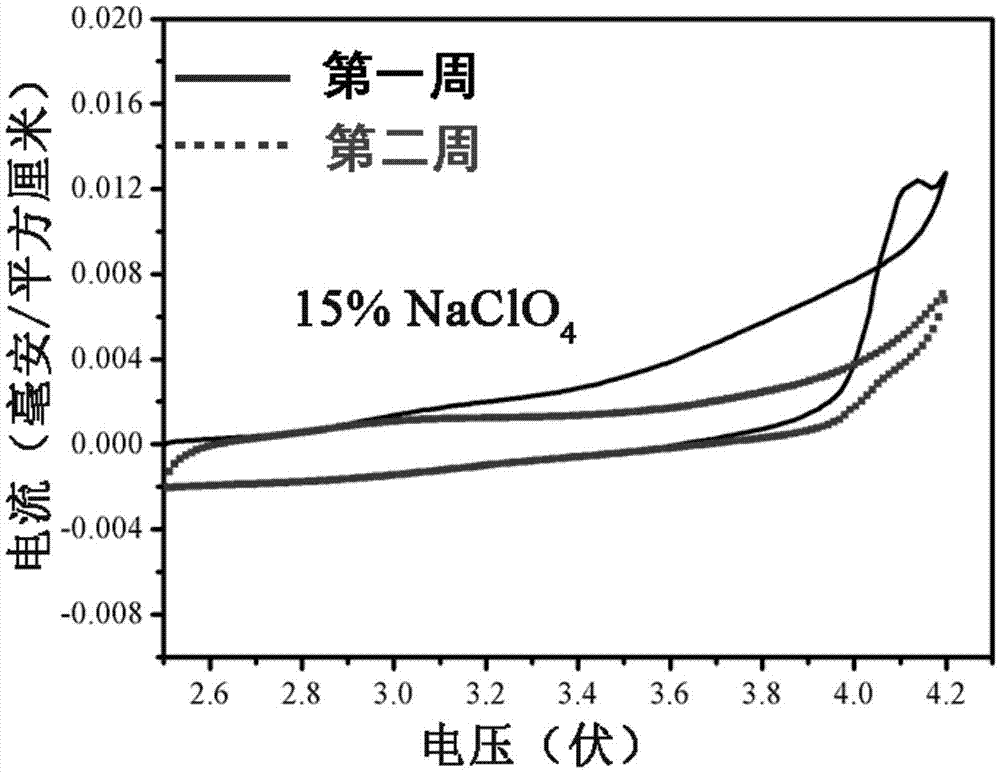

[0040] The assembled secondary batteries 1A-1I and the control secondary battery 1 were subjected to a cyclic voltammetry test, wherein the voltage range was 2.5-4.2V. The cyclic voltammetry curves of secondary battery 1A-1I and contrast secondary battery 1 are respectively as follows Figures 1A-1I and figure 2 displayed.

[0041] After the cyclic voltammetry test for 25 weeks, the secondary batteries 1A-1I and the control secondary battery 1 were disassembled in the glove box, and the aluminum foil was taken out, cleaned with dimethyl carbonate, dried in a vacuum transition chamber, and then scanned. Observe the corrosion situati...

Embodiment 3

[0045] 70mg sodium ion secondary battery cathode material (Na 0.9 Ni 0.4 mn0.4 Ti 0.2 o 2 ) as an active substance, mixed with 20mg carbon black and 200μL polyvinylidene fluoride (PVDF) in N,N-dimethylpyrrolidone (NMP) solution (concentration: 50mg / mL) to form a slurry, and coated on the current collector aluminum foil , dried at 120°C to make electrode sheets. Put the dried electrode sheet into an argon glove box, assemble a battery with a sodium sheet with a diameter of 10mm as the negative electrode, and add the electrolytes 1-9 prepared in Example 1 and the control electrolyte respectively to completely infiltrate the electrode sheet , were assembled into experimental secondary batteries, labeled as secondary batteries 2A-2I and control secondary battery 2, respectively.

[0046] Charge and discharge tests were performed on the secondary batteries 2A-2I and the control secondary battery 2 at a rate of 0.2C, respectively. The charge cut-off voltage is 4V, the discharge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com