Nisin/chitosan nano particle antibacterial film, preparation method and application

A nisin and chitosan nanotechnology, applied in the field of food antibacterial and fresh-keeping, can solve the problems of aggregation and decline, and reduce the biological activity of encapsulated substances, so as to prolong the shelf life, inhibit the growth of pathogenic microorganisms, and achieve biocompatibility. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The characterization of embodiment 1 nisin / chitosan nanoparticles

[0031] 1 Experimental materials

[0032]

[0033] 2 Experimental methods

[0034] 1) Preparation and characterization of nisin / chitosan nanoparticles

[0035] ① Take 500 μL of acetic acid and add deionized water to prepare 50 mL of 1% (V / V) acetic acid solution, and stir magnetically for 20 minutes.

[0036] ② Weigh 200mg of chitosan and add it to the above acetic acid solution to prepare a 4mg / mL chitosan solution, stir for 30min, then absorb 25mL of chitosan solution and add 25mL of deionized water to dilute.

[0037] ③Weigh 50mg of γ-polyglutamic acid and add to 25mL deionized water, stir for 10min.

[0038] ④ Weigh 500 mg of nisin and add it to 25 mL of deionized water, and stir for 15 min.

[0039] ⑤ Add nisin solution (20mg / mL) dropwise to γ-polyglutamic acid solution (2mg / mL) and stir for 30min.

[0040] ⑥ Add 50 mL of the above solution dropwise to 50 mL of chitosan solution (2 mg / mL), a...

Embodiment 2

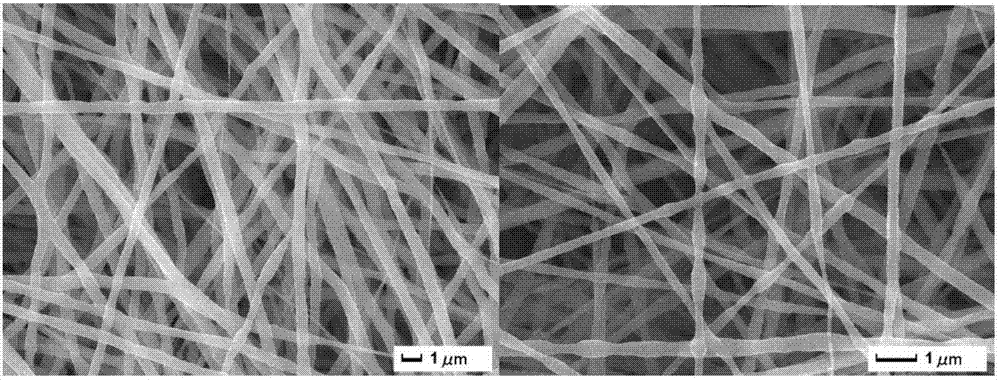

[0052] The characterization of embodiment 2 nisin / chitosan nanoparticle antibacterial film

[0053] 1 Experimental materials

[0054] Polyethylene oxide SIGMA-ALDRICH

[0055] Embodiment 1 chitosan nanoparticle

[0056] 2 Experimental methods

[0057] 1) Preparation of nisin / chitosan nanoparticle antibacterial film

[0058] ①Dissolve the chitosan nanoparticles obtained by centrifugation in 99.75mL deionized water.

[0059] ② Weigh 600 mg of polyethylene oxide and slowly add it into 9.4 g of chitosan nanoparticle solution and stir overnight to prepare a 6 wt% (g / g) polyethylene oxide spinning precursor solution.

[0060] ③The syringe absorbs 5mL of the spinning precursor solution, the electrospinning voltage is 20kV, the propulsion rate is 0.6mL / h, the receiving distance is 15.5cm, the air humidity is controlled below 35%, and the nanofibers are obtained after 3 hours by using the flat plate collection method membrane.

[0061] ④According to the spinning step, without add...

Embodiment 3

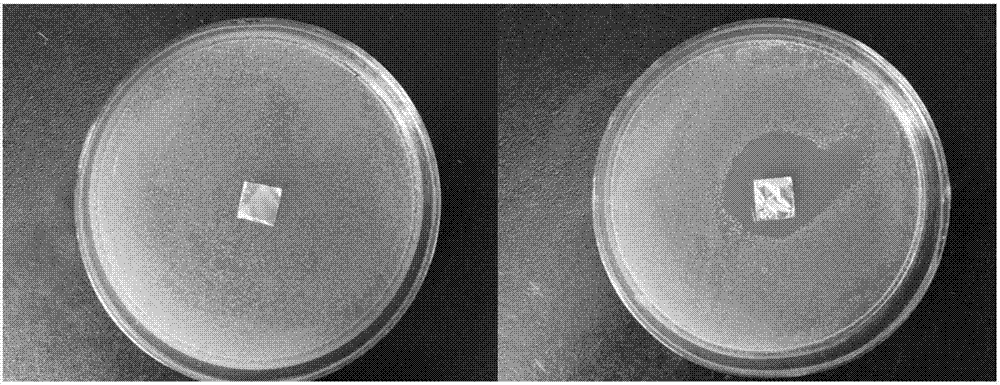

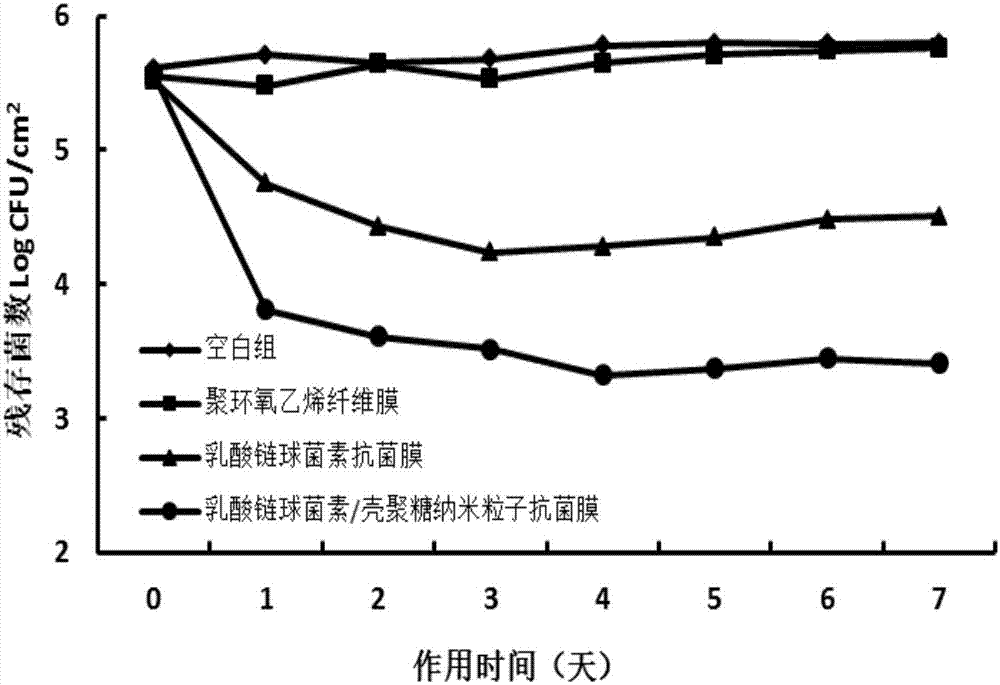

[0066] The bacteriostatic zone experiment of embodiment 3 nisin / chitosan nanoparticle antibacterial film

[0067] 1 Experimental materials

[0068] Polyethylene oxide fiber film; nisin / chitosan nanoparticle antibacterial film

[0069] Listeria

[0070] 2 Experimental methods

[0071] 1) Prepare bacterial liquid

[0072] Inoculate Listeria in PYG liquid medium, place in an air shaker, and shake and culture at 37°C and 140rpm for 24 hours to obtain a bacterial suspension in the logarithmic growth phase. After mixing with a shaker, dilute 10000 times (approximately 10 4 cfu / mL).

[0073] 2) Electrospinning fiber membrane treatment

[0074] Prepare nisin / chitosan nanoparticle antibacterial film and polyethylene oxide fiber film according to Examples 1 and 2, and dry in an oven for 4 hours. The film was cut into a size of 1 cm×1 cm and placed under ultraviolet light for sterilizing treatment for 1 h for later use.

[0075] 3) Inhibition zone experiment

[0076] The sterili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com