Self-healing ceramic matrix composite combustion chamber flame tube and its preparation method and application

A composite material and combustion chamber technology, which can be used in combustion methods, combustion chambers, combustion equipment, etc., can solve problems such as restricting the application of SiC ceramic matrix composite materials, damage to the interface phase and fiber oxidation, accelerated material damage and corrosion, etc. Good mechanical properties, high degree of densification, strong anti-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

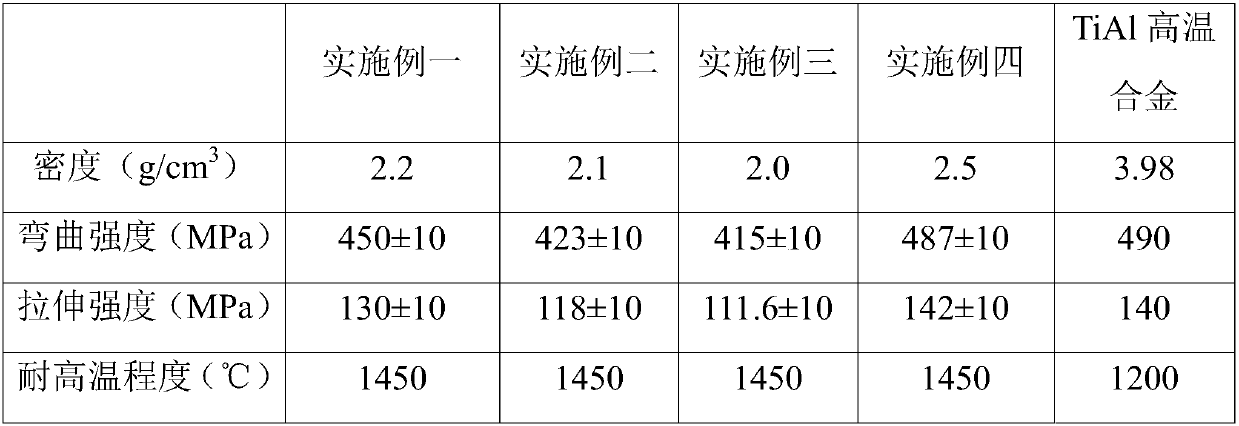

Examples

preparation example Construction

[0028] The invention provides a method for preparing a composite material combustion chamber flame tube, comprising the following steps:

[0029] S1: The SiC interface was prepared by the chemical vapor deposition method on the prefabricated body of the combustor flame tube; the reaction gas of the chemical vapor deposition method was trichloromethylsilane; Braided, wherein, the braiding angle is 20-45°, the volume fraction of silicon carbide fiber is 30%-50%; the chemical vapor deposition method is specifically: trichloromethylsilane as the reaction gas, hydrogen as the carrier gas, argon gas It is a diluent gas, the deposition temperature is 1100-1230°C, the pressure is 1-5kPa, and the deposition time is 5-15h; wherein, the volume ratio of hydrogen to trichloromethylsilane is 1:8-1:12.

[0030] S2: Using the mixed solution of polycarbosilane and xylene as the precursor solution, the product obtained in step S1 is densified by the precursor impregnation and cracking method; t...

Embodiment 1

[0036] The silicon carbide fiber is woven into the combustor flame tube preform by three-dimensional four-step method, wherein the weaving angle is 40°, and the volume fraction of silicon carbide fiber is 35%; the obtained combustor flame tube preform is prepared by chemical vapor deposition method. interface, in which trichloromethylsilane is used as the reaction gas, hydrogen is used as the carrier gas, argon is used as the diluent gas, the volume ratio of hydrogen to trichloromethylsilane is 1:10, the deposition temperature is 1130°C, and the pressure is 4.5kPa. The deposition time was 8 hours, and the thickness of the prepared SiC interface was 6 μm.

[0037] The product obtained above was impregnated with a mixed solution of polycarbosilane and xylene under vacuum conditions for 6 hours, and then dried at 120°C; the dried product was cracked at 1000°C in nitrogen for 4 hours; the precursor impregnation cracking method was repeated for 10 cycles , the obtained silicon carb...

Embodiment 2

[0040] The silicon carbide fiber is woven into the combustor flame tube preform by three-dimensional four-step method, wherein the weaving angle is 30°, and the volume fraction of silicon carbide fiber is 35%; the obtained combustor flame tube preform is prepared by chemical vapor deposition method. interface, in which trichloromethylsilane is used as the reaction gas, hydrogen is used as the carrier gas, and argon is used as the diluent gas. The volume ratio of hydrogen to trichloromethylsilane is 1:9, the deposition temperature is 1150°C, and the pressure is 3kPa. The time is 6 hours, and the thickness of the prepared SiC interface is 4 μm.

[0041] The product obtained above was impregnated with a mixed solution of polycarbosilane and xylene under vacuum conditions for 5 hours, and then dried at 120°C; the dried product was cracked at 950°C in nitrogen for 6 hours; the precursor dipping cracking method was repeated for 8 cycles , the obtained silicon carbide matrix has a de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com