Purification method of memantine hydrochloride

A technology of memantine hydrochloride and purification method, which is applied in the field of medicinal chemistry, can solve the problems of simple process and low pollution, and achieve the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

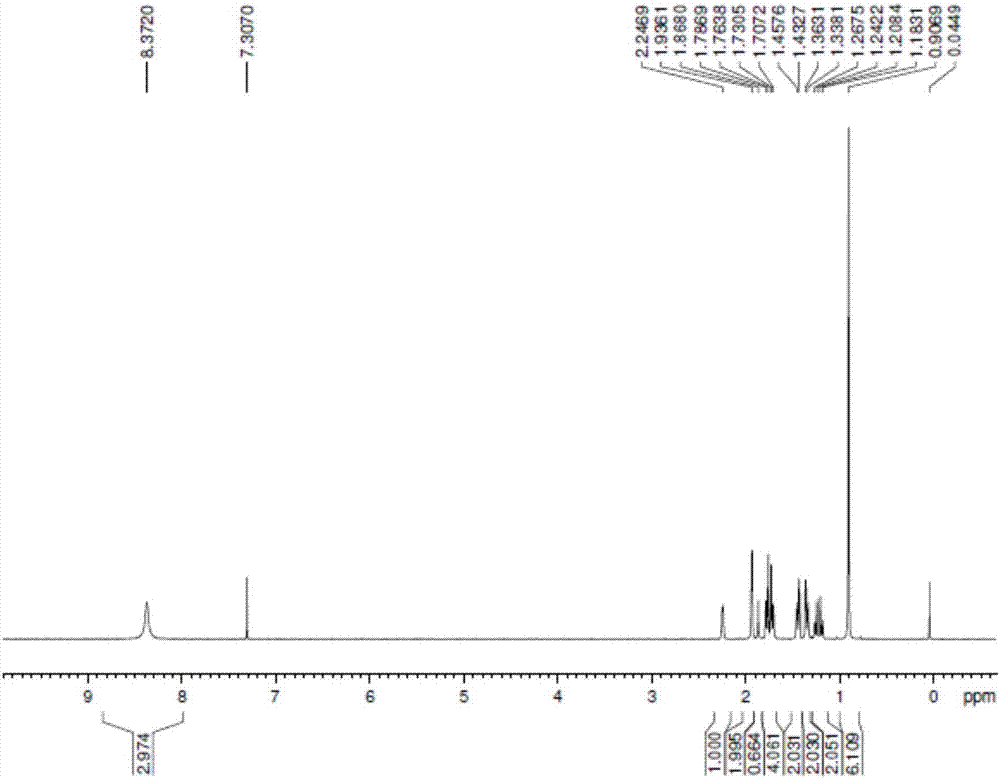

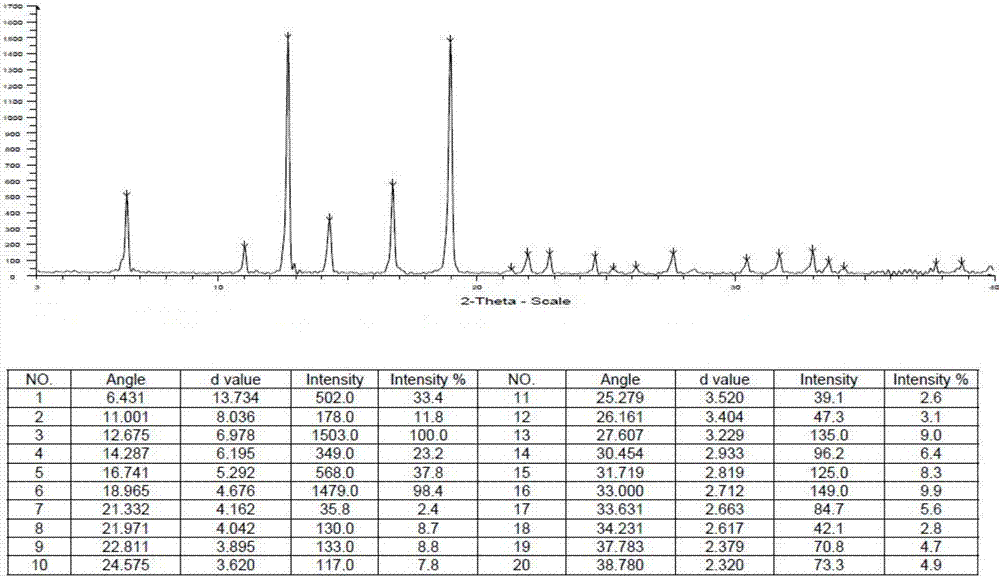

Embodiment 1

[0035] Add 5.0 g of crude memantine hydrochloride to the reaction flask, add 15 mL of water, heat and reflux and stir for 30 minutes, cool to -20~5°C, stir and keep warm for crystallization for 3 hours, filter, wash the filtrate with acetone to obtain white crystalline powder, and vacuum dry at 60°C 2.6 g of memantine hydrochloride in the form of crystal form I was obtained, with a GC purity of 99.51%, a maximum mono-heterogeneity of 0.43%, and a yield of 52%.

Embodiment 2

[0037] Add 5.0g of crude memantine hydrochloride to the reaction flask, add 10mL of ethanol, heat and reflux and stir for 30 minutes, cool to -20~5℃, stir and keep warm for crystallization for 3 hours, filter, wash the filtrate with acetone to obtain white crystalline powder, vacuum at 60℃ After drying, 1.9 g of memantine hydrochloride in the form of crystal form I was obtained, with a GC purity of 99.34%, a maximum mono-heterogeneity of 0.54%, and a yield of 38%.

Embodiment 3

[0039] Add 5.0g of crude memantine hydrochloride to the reaction flask, add 250mL of acetone, heat and reflux and stir for 30 minutes, cool to -20~5℃, stir and keep warm for crystallization for 3 hours, filter, wash the filtrate with acetone to obtain white crystalline powder, vacuum at 60℃ After drying, 1.3 g of memantine hydrochloride in the form of crystal form I was obtained, with a GC purity of 99.18%, a maximum mono-heterogeneity of 0.77%, and a yield of 26%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com