A kind of tetraalkyl peroxycarboxylate ammonium salt compound and its preparation method and application

A technology of ammonium peroxycarboxylate and tetraalkylperoxycarboxylate, applied in the field of medicinal chemistry, can solve the problems of poor permeability, short disinfection time and the like, and achieve the effect of good permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

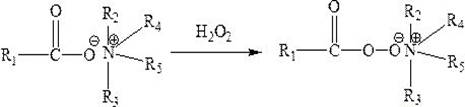

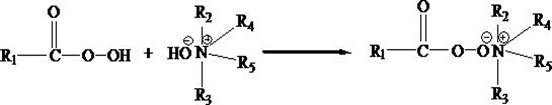

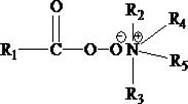

Method used

Image

Examples

Embodiment 1

[0035] (1) In a 1000ml four-necked flask equipped with a thermometer, a mechanical stirrer, a reflux condenser and a constant pressure funnel, add 120g of acetic acid, 10g of organic phosphoric acid and 2g of disodium edetate;

[0036] (2) Start the stirrer, and when the temperature of the system reaches 5° C., start to drop 150 g of 50% hydrogen peroxide. Add dropwise in 1 hour;

[0037] (3) continue to react for 12 hours;

[0038] (4) Keeping the temperature of the system at 10°C, add tetrabutylammonium hydroxide dropwise until the system is neutral;

[0039] (5) Continue to react for 2 hours under stirring to obtain tetrabutyl ammonium peroxyacetate aqueous solution, which can be directly used for disinfection;

[0040] (6) Remove moisture by distillation under reduced pressure, and refine the product tetrabutyl ammonium peroxyacetate with methanol.

Embodiment 2

[0042] (1) In a 1000ml four-neck flask equipped with a thermometer, a mechanical stirrer, a reflux condenser and a constant pressure funnel, add 110g propionic acid, 5g p-toluenesulfonic acid and 0.5g organic phosphoric acid;

[0043] (2) Start the agitator, and when the temperature of the system reaches 15° C., start to drop 120 g of 50% hydrogen peroxide. Add dropwise in 1 hour;

[0044] (3) continue to react for 12 hours;

[0045] (4) Keeping the temperature of the system at 10° C., dropwise adding tetraethylammonium hydroxide until the system is neutral;

[0046] (5) Continue to react for 2 hours under stirring to obtain tetraethyl ammonium peroxyacetate aqueous solution, which can be directly used for disinfection;

[0047] (6) Remove moisture by distillation under reduced pressure, and refine the product tetraethyl ammonium peroxyacetate with methanol.

Embodiment 3

[0049] (1) In a 1000ml four-necked flask equipped with a thermometer, a mechanical stirrer, a reflux condenser and a constant pressure funnel, add 130g valeric acid, 15g organic phosphoric acid and 5g disodium edetate;

[0050] (2) Start the agitator, and when the temperature of the system reaches 15° C., start to drop 180 g of 50% hydrogen peroxide. Add dropwise in 1 hour;

[0051] (3) Continue to react for 15 hours;

[0052] (4) Keeping the temperature of the system at 10°C, add tetrabutylammonium hydroxide dropwise until the system is neutral;

[0053] (5) Continue to react for 2 hours under stirring to obtain tetrabutyl ammonium peroxyvalerate aqueous solution, which can be directly used for disinfection;

[0054] (6) Remove moisture by distillation under reduced pressure, and refine the product tetrabutyl ammonium peroxyvalerate with methanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com