Thin film assembled by gold nanoparticles and its preparation method and use

A technology of gold nanoparticles and thin films, which is applied in the field of thin films assembled by gold nanoparticles and its preparation, can solve the problems of affecting the uniformity of SERS signals, restricting SERS activity, and high SERS activity, so as to reduce the interference of background signals and achieve high SERS Activity, activity-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The concrete steps of preparation are:

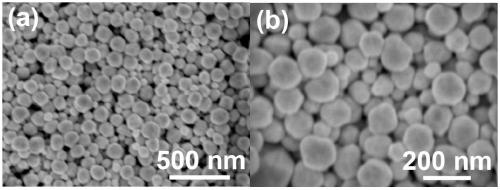

[0038] After first cleaning the conductive substrate with ethanol and deionized water, sputter a 10nm thick gold film on the surface of the conductive substrate; wherein the conductive substrate is an indium tin oxide glass substrate, and obtain a conductive substrate covered with a gold film on its surface. end. Then put the graphite sheet as the anode and the conductive substrate covered with gold film as the cathode in the gold electrolyte, at 20μA / cm 2 After electrodeposition at a constant current for 120 minutes, it was washed once with deionized water, and then dried at 40°C; the gold electrolyte was 0.2 g / L chloroauric acid aqueous solution and 200 g / L polyvinylpyrrolidone aqueous solution The mixed solution, wherein the polyvinylpyrrolidone its molecular weight is 40000 polyvinylpyrrolidone, made approximately figure 1 A thin film assembled with gold nanoparticles is shown.

Embodiment 2

[0040] The concrete steps of preparation are:

[0041] After first cleaning the conductive substrate with ethanol and deionized water, sputter a 15nm thick gold film on the surface of the conductive substrate; wherein the conductive substrate is an indium tin oxide glass substrate, and obtain a conductive substrate covered with a gold film on its surface. end. Then put the graphite sheet as the anode and the conductive substrate covered with gold film as the cathode in the gold electrolyte, at 140μA / cm 2 After electrodeposition at a constant current for 95 minutes, it was washed twice with deionized water, and then dried at 45°C; the gold electrolyte was 2.5g / L chloroauric acid aqueous solution and 150g / L polyvinylpyrrolidone aqueous solution The mixed solution, wherein the polyvinylpyrrolidone its molecular weight is 40000 polyvinylpyrrolidone, made approximately figure 1 A thin film assembled with gold nanoparticles is shown.

Embodiment 3

[0043] The concrete steps of preparation are:

[0044]After first cleaning the conductive substrate with ethanol and deionized water, sputter a 20nm thick gold film on the surface of the conductive substrate; wherein the conductive substrate is an indium tin oxide glass substrate, and obtain a conductive substrate covered with a gold film on its surface. end. Then the graphite sheet is used as the anode, and the conductive substrate covered with gold film on the surface is used as the cathode, placed in the gold electrolyte, at 260μA / cm 2 After electrodeposition at a constant current for 70 minutes, it was washed twice with deionized water, and then dried at 50°C; wherein, the gold electrolyte was a mixture of 5 g / L chloroauric acid aqueous solution and 100 g / L polyvinylpyrrolidone aqueous solution. Mixed solution, polyvinylpyrrolidone wherein its molecular weight is the polyvinylpyrrolidone of 40000, makes as figure 1 A thin film assembled with gold nanoparticles is shown. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com