Preparation method of metal organic framework film modified by chlorophyll b and application thereof to photocatalytic reduction carbon dioxide

A metal-organic framework and chlorophyll technology, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve the problems of limited development and application, cumbersome operation, and pollution, and achieve high light energy utilization rate, high photocatalytic efficiency, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

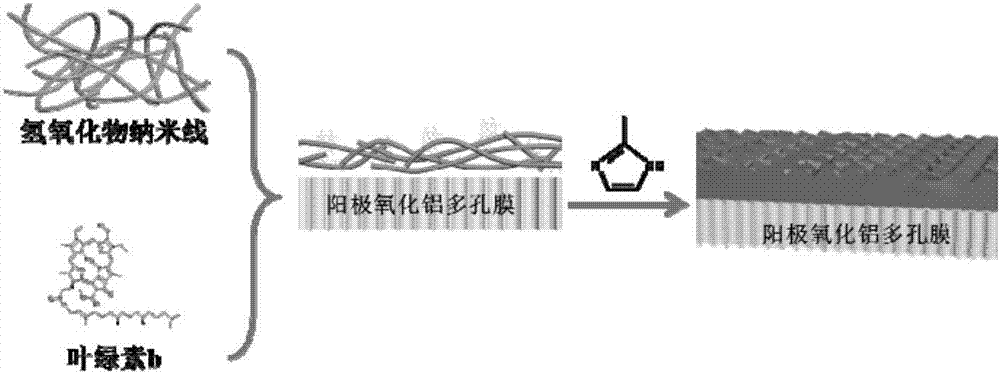

[0033] 1) Mix 30ml copper hydroxide nanowire solution with 1ml 1mg / L chlorophyll b solution, stir magnetically for 5min, and vacuum filter directly on the anodized aluminum porous membrane to form a composite membrane of nanowire and chlorophyll b, anodize The aluminum porous membrane has a diameter of 2.5 cm, a pore diameter of 200 nm, and a porosity of 50%. ;

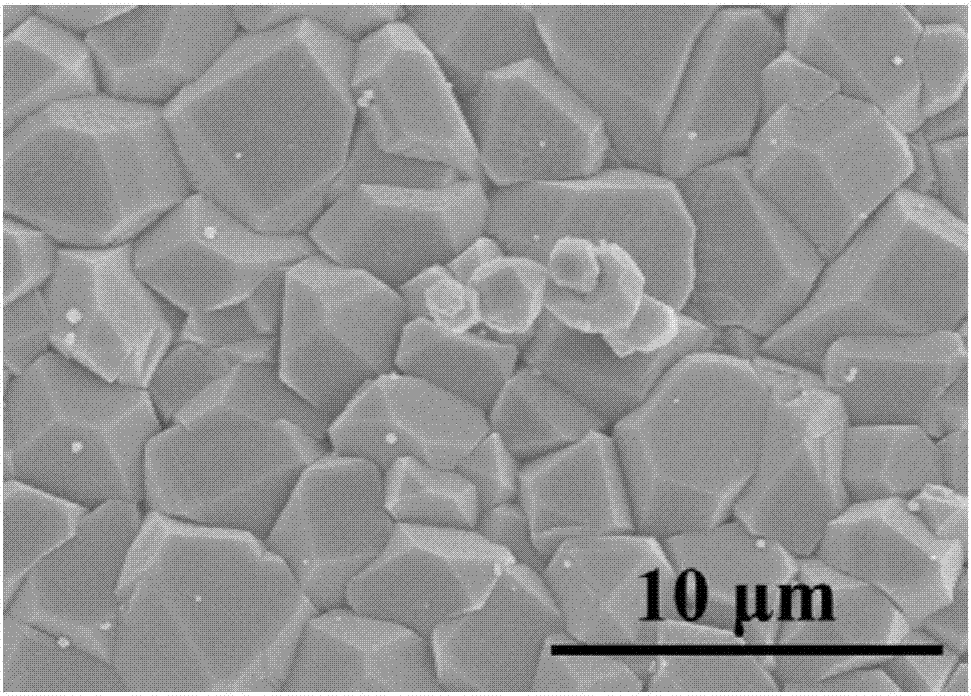

[0034] 2) Put the composite film of nanowires and chlorophyll b into 10ml, 10mM trimesic acid solution (the volume of ethanol and water is 1:1), and react at room temperature for 2 hours. After the reaction, wash 3 times with the mixed solvent of the same ratio to obtain the HKUST-1 film modified by chlorophyll b (molecular formula is Cu 3 (BTC) 2 ·3H 2 O), see figure 2 . figure 2 The chlorophyll b-modified HKUST-1 film shown is a polycrystalline film with good grain intergrowth and continuous film without cracks.

Embodiment 2

[0036] 1) Mix 30ml of copper hydroxide nanowire solution with 1ml of 10mg / L chlorophyll b solution, stir magnetically for 5min, and vacuum filter directly on the anodized aluminum porous membrane to form a composite membrane of nanowire and chlorophyll b, anodize The aluminum porous membrane has a diameter of 2.5 cm, a pore diameter of 200 nm, and a porosity of 50%. ;

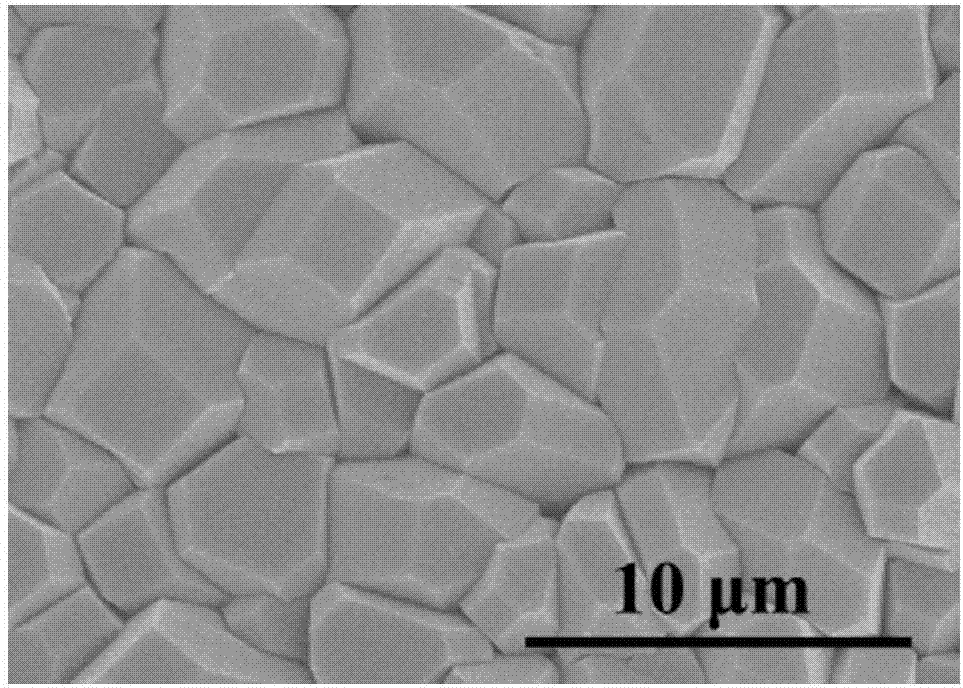

[0037]2) Put the composite film of nanowires and chlorophyll b into 10ml, 10mM trimesic acid solution (the volume of ethanol and water is 1:1), and react at room temperature for 2 hours. After the reaction, wash 3 times with the mixed solvent of the same ratio to obtain the HKUST-1 film modified by chlorophyll b (molecular formula is Cu 3 (BTC) 2 ·3H 2 O), see image 3 . image 3 The chlorophyll b-modified HKUST-1 film shown is a polycrystalline film with good grain intergrowth and continuous film without cracks.

Embodiment 3

[0039] 1) Mix 30ml copper hydroxide nanowire solution with 1ml 100mg / L chlorophyll b solution, stir magnetically for 5min, and vacuum filter directly on the anodized aluminum porous membrane to form a composite membrane of nanowire and chlorophyll b, anodize The aluminum porous membrane has a diameter of 2.5 cm, a pore diameter of 200 nm, and a porosity of 50%. ;

[0040] 2) Put the composite film of nanowires and chlorophyll b into 10ml, 10mM trimesic acid solution (the volume of ethanol and water is 1:1), and react at room temperature for 2 hours. After the reaction, wash 3 times with the mixed solvent of the same ratio to obtain the HKUST-1 film modified by chlorophyll b (molecular formula is Cu 3 (BTC) 2 ·3H 2 O), see Figure 4 . Figure 4 The chlorophyll b-modified HKUST-1 film shown is a polycrystalline film with good grain intergrowth and continuous film without cracks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com