Boron nitride composite mesoporous oxide nickel-based catalyst and preparation method thereof

A boron nitride composite mesoporous, nickel-based catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve inhibition of migration and aggregation, rapid preparation process , highly dispersed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

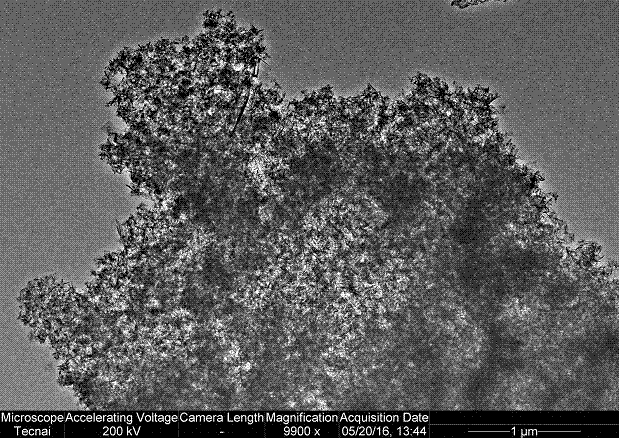

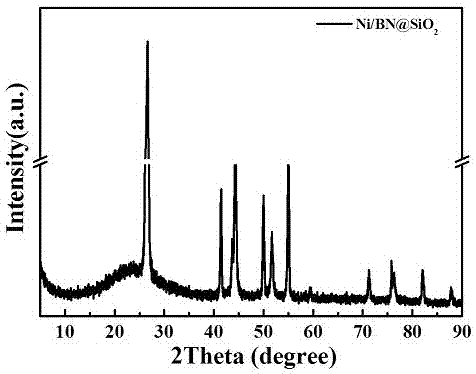

[0029] Weigh 0.400 g of boron nitride and 0.150 g of nickel nitrate and dissolve them in a mixed solution of water and ethanol, add 0.600 g of surface modifier CTAB and 1.80 mL of ammonia water, stir ultrasonically for 1 h, and dissolve 0.6 g of mesoporous oxide precursor TEOS Added dropwise and stirred vigorously for 6 h. The nickel loading was 6.5 wt%. Centrifugal washing with water and alcohol 3 times each, 60 o C drying for 12 h. The heating rate in the air atmosphere is 2 o C / min, 600 o C calcined for 4 h. Use hydrogen to program temperature reduction, first pass N 2 at 300 o C for 30 min, cooled to room temperature with 10 vol% H 2 / N 2 Mixed gas (30mL / min) 750 o C reduction for 1 h, a new structure nickel-based catalyst of boron nitride composite mesoporous oxide was obtained.

[0030] Test the catalytic activity of the above catalyst: Weigh 0.120 g (40-60 mesh) of the prepared catalyst and put it into a fixed bed quartz tube reactor for catalyst performance t...

Embodiment 2

[0032]Weigh 0.400 g of boron nitride and 0.150 g of nickel nitrate and dissolve them in a mixed solution of water and ethanol, add 0.600 g of surface modifier CTAB and 1.80 mL of ammonia water, stir ultrasonically for 1 h, and dissolve 0.6 g of mesoporous oxide precursor TEOS Add dropwise and stir vigorously for 1 h. The nickel loading was 6.5 wt%. Centrifugal washing with water and alcohol 3 times each, 60 o C drying for 12 h. The heating rate in the air atmosphere is 2 o C / min, 600 o C calcined for 4 h. Use hydrogen to program temperature reduction, first pass N 2 at 300 o C for 30 min, cooled to room temperature with 10 vol% H 2 / N 2 Mixed gas (30mL / min) 750 o C reduction for 1 h, a new structure nickel-based catalyst of boron nitride composite mesoporous oxide was obtained.

[0033] Test the catalytic activity of the above catalyst: Weigh 0.120 g (40-60 mesh) of the prepared catalyst and put it into a fixed bed quartz tube reactor for catalyst performance test, C...

Embodiment 3

[0035] Weigh 0.400g of boron nitride and 0.130g of nickel acetylacetonate and dissolve in the mixed solution of water and ethanol, add 0.600 g of surface modifier CTAB and 1.80 mL of ammonia water, stir ultrasonically for 1 h, and dissolve 0.6 g of mesoporous oxide precursor TEOS Added dropwise and stirred vigorously for 6 h. The nickel loading was 6.5 wt%. Centrifugal washing with water and alcohol 3 times each, 60 o C drying for 12 h. The heating rate in the air atmosphere is 2 o C / min, 600 o C calcined for 4 h. Use hydrogen to program temperature reduction, first pass N 2 at 300 o C for 30 min, cooled to room temperature with 10 vol% H 2 / N 2 Mixed gas (30mL / min) 750 o C reduction for 1 h, a new structure nickel-based catalyst of boron nitride composite mesoporous oxide was obtained.

[0036] Test the catalytic activity of the above catalyst: Weigh 0.120 g (40-60 mesh) of the prepared catalyst and put it into a fixed bed quartz tube reactor for catalyst performanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com