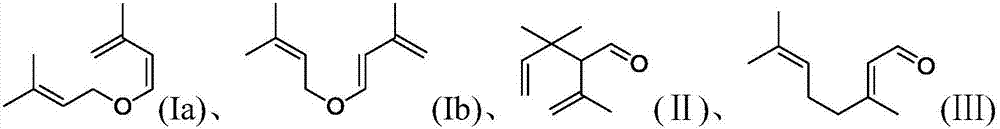

Method for preparation of citral

A technology of citral and inhibitors, which is applied in the field of preparation of citral, can solve the problems of violent heat release, side reactions, and difficulty in removing reaction heat from the reactor, and achieve enhanced heat and mass transfer effects, high selectivity, and shortened side reactions the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 The preparation of cis / trans-isopentenyl-3-methylbutadiene ether

[0026] Add 774g prenol (about 9mol), 84g prenaldehyde (about 1mol) and 1.15g phosphoric acid (mass content 85%, about 0.01mol) into the bottom of the rectification column, the number of theoretical plates of the rectification column is 9 , the temperature at the bottom of the tower is 110°C, the vacuum at the top of the tower is 5KPa, and the reflux ratio is 1:10. Prenyl alcohol and water are extracted at the top of the tower. After heating the tower kettle for 5 hours, when there is almost no reflux at the top of the tower, stop heating. The product obtained in the tower kettle is isopentenyl prenyl aldehyde, and the acetal content is 99% as detected by the gas phase. Raise the temperature of the tower kettle to 150°C, the vacuum at the top of the tower is 2KPa, the reflux ratio is 1:3, and the cis / trans-prenyl-3-methylbutadiene ether and isopentenol are produced at the top of the tower . ...

Embodiment 2

[0028]The length of the microreactor preheating tube is 0.5m, the inner diameter is 1mm, and the temperature of the external constant temperature circulating bath of the preheating pipeline is 180°C. The temperature of the external constant temperature circulating bath of the microreactor is 200°C, and the temperature of the external constant temperature circulating bath of the micro heat exchanger is 120°C. The length of the delay line is 6m and the inner diameter is 4mm. The temperature of the constant temperature circulating bath outside the delay pipeline is 180°C. Feed the raw materials (cis / trans-prenyl-3-methylbutadiene ether mass content 97%, prenol content 2.5%) through the preheating pipeline at a rate of 15mL / min, formic acid The tert-butyl ester is pumped into the microreactor simultaneously with the raw material in the amount of 0.5mol% of the raw material, and flows through the micro heat exchanger and the delay pipeline (the pressure behind the micro heat excha...

Embodiment 3

[0030] The length of the preheating tube of the micro heat exchanger is 0.5m, the inner diameter is 1mm, the temperature of the external constant temperature circulating bath of the preheating pipeline is 200°C, the reaction liquid directly enters the micro heat exchanger, and the temperature of the external constant temperature circulating bath of the micro heat exchanger is 150°C. The length of the delay line is 6m and the inner diameter is 4mm. The temperature of the constant temperature circulating bath outside the delay pipeline is 180°C. Feed the raw materials (cis / trans-prenyl-3-methylbutadiene ether mass content 97%, prenol content 2.5%) through the preheating pipeline at a rate of 20mL / min, acetic acid The tert-butyl ester is pumped into the micro heat exchanger at the same time as the raw material in the amount of 2.0mol% of the raw material, and then enters the delay pipeline (the pressure after the micro heat exchanger will be 0.2MPa, and the reaction solution stay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com