UV-curable polyurethane acrylate photosensitive resin and its preparation method and use

A polyurethane acrylate, photosensitive resin technology, used in polyurea/polyurethane coatings, polyurea/polyurethane adhesives, applications, etc., can solve the problem of poor yellowing resistance and chemical resistance, poor mechanical properties, slow curing rate and other problems, to achieve the effect of improving hydrophobicity and chemical resistance, reducing synthesis cost and fast curing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

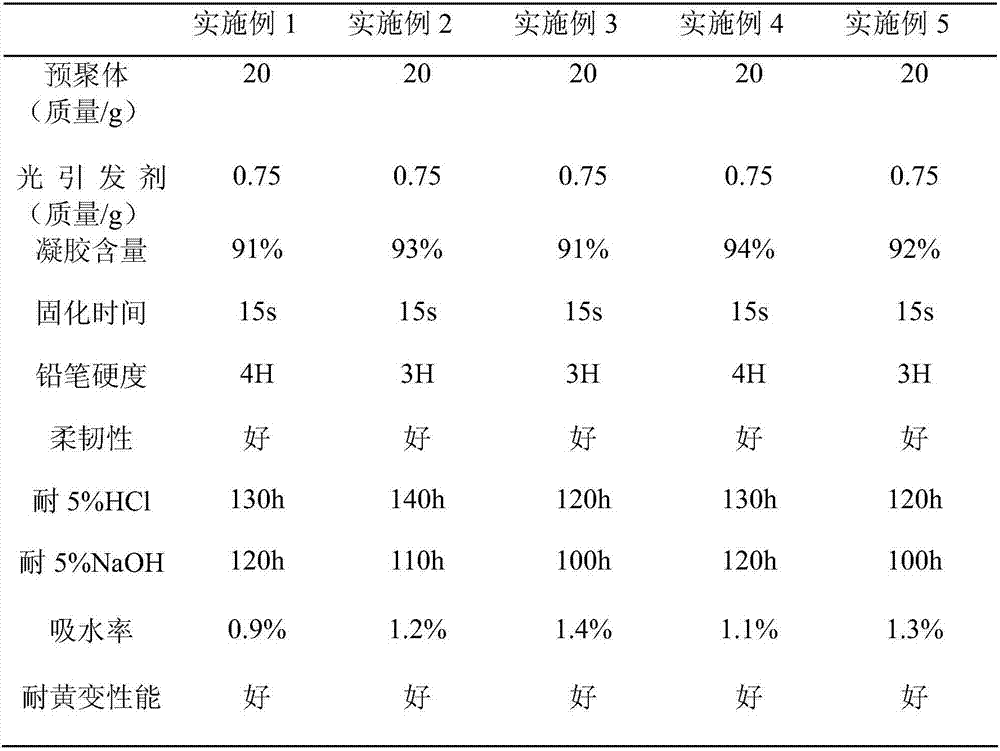

Examples

Embodiment 1

[0042] A kind of urethane acrylate photosensitive resin cured by ultraviolet light is prepared by the following method:

[0043] 1. Mix 15.8g (0.053mol) of cardanol, 11.3g (0.102mol) of 3-chloro-1,2-propanediol and 35.1ml (0.602mol) of absolute ethanol, and maintain the temperature at 75 under magnetic stirring ℃, dropwise add 22.2g mass fraction of 20% sodium hydroxide (0.111mol), dropwise time is 1.5h, after dropwise addition, react for 20h; cool, filter the precipitated salt, wash with distilled water, reduce pressure at 60°C Ethanol and water are distilled off to synthesize cardanol etherified glycol (I);

[0044] 2. Mix 5.9g (0.050mol) of m-xylylene diisocyanate and 0.08g of dibutyltin dilaurate, feed nitrogen gas, keep the temperature at 5°C, and slowly add it dropwise to the mixture containing 15.9g (0.042mol) of cardanol etherified diol (I) in 15ml (0.195mol) of DMF, the dropwise addition time is 1h, after the dropwise addition is completed, the temperature is raised to...

Embodiment 2

[0048] A kind of urethane acrylate photosensitive resin cured by ultraviolet light is prepared by the following method:

[0049] 1. Mix 15.8g (0.053mol) of cardanol, 10.8g (0.098mol) of 3-chloro-1,2-propanediol and 38.4ml (0.659mol) of absolute ethanol, and maintain the temperature at 65 ℃, dropwise add 28.1g mass fraction of 15% sodium hydroxide (0.105mol), dropwise time is 1.0h, after dropwise addition, react for 18h; cool, filter the precipitated salt, wash with distilled water, reduce pressure at 65°C Ethanol and water are distilled off to synthesize cardanol etherified dihydric alcohol (I).

[0050] 2. Mix 12.5g (0.050mol) of diphenylmethylene diisocyanate and 0.08g drop of stannous octoate, feed nitrogen gas, keep the temperature at 0°C, and slowly add dropwise to the solution containing 13.5 17.9g (0.048mol) of cardanol etherified diol (I) in ml (0.175mol) of DMF, the dropwise addition time is 2h. g (0.005mol) of cardanol, the time of dropping is 0.5h, after the dropw...

Embodiment 3

[0054] A kind of urethane acrylate photosensitive resin cured by ultraviolet light is prepared by the following method:

[0055] 1. Mix 15.8g (0.053mol) of cardanol, 12.0g (0.109mol) of 3-chloro-1,2-propanediol and 33.2ml (0.569mol) of absolute ethanol, and maintain the temperature at 70 under magnetic stirring ℃, dropwise add 20.0g mass fraction of 25% sodium hydroxide (0.125mol), dropwise time is 0.5h, after dropwise addition, react for 15h; cool, filter the precipitated salt, wash with distilled water, reduce pressure at 70°C Ethanol and water are distilled off to synthesize cardanol etherified dihydric alcohol (I).

[0056] 2. Mix 13.1g (0.050mol) of dimethyl diphenylmethane diisocyanate and 0.08g drop of di(dodecylsulfide) dibutyltin, pass in nitrogen, maintain the temperature at 10°C, and stir it magnetically Slowly add dropwise to the cardanol etherified glycol (I) of 16.9g (0.045mol) that contains 15.4ml (0.200mol) DMF, the time of adding is 1.5h, after dropping, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com