Thermally conductive composite material and preparation method thereof

A heat-conducting composite material and thermoplastic technology, which is applied in the field of composite materials, can solve the problems of poor thermal conductivity of composite materials, achieve the effects of improving heat transfer capacity, reducing interface thermal resistance and phonon scattering, and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

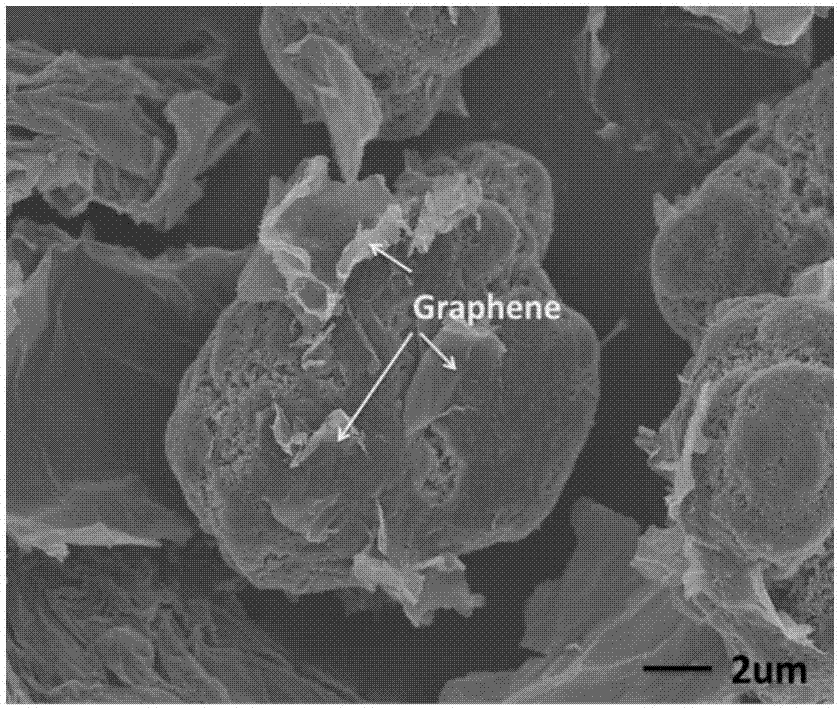

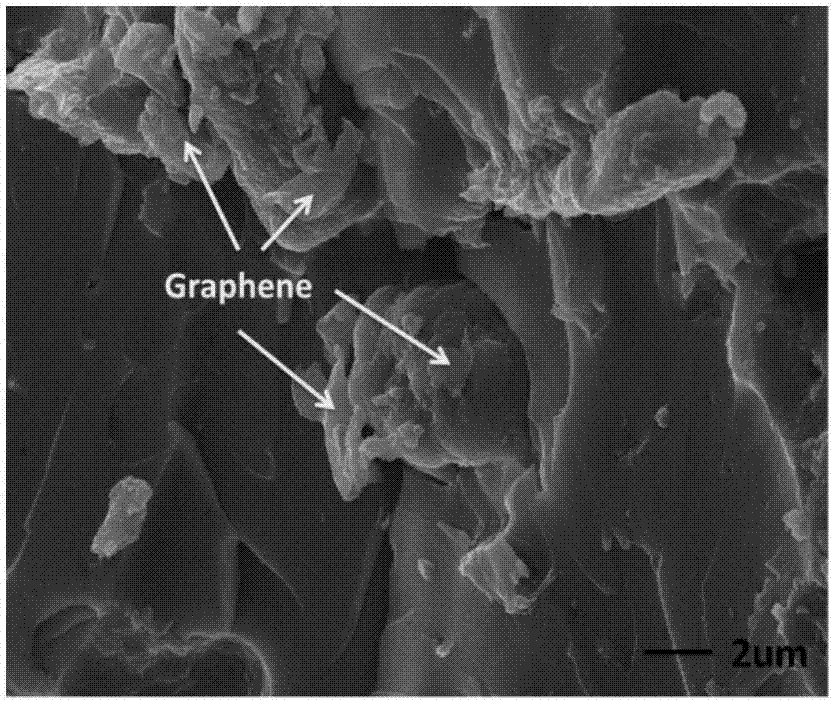

Image

Examples

Embodiment 1

[0026] (1) Disperse 0.1 g of reduced graphene in acetone at room temperature, add 1 g of polyamide (PA) micropowder after the dispersion is uniform, use phosphate buffer to adjust the pH value of the solution (PH = 6), and stir to promote graphene and thermoplasticity. Electrostatic adsorption of particles to obtain a stable suspension of self-assembled mixed filler; (2) Add the above suspension to 15.3g of bisphenol A epoxy resin and stir evenly, then add 4.6g of modified aromatic amine curing agent, vacuum After removing the solvent, heat according to the curing system to prepare a thermally conductive resin-based composite material. The thermal conductivity of the composite material was tested, and the thermal conductivity was 0.245w / m.k.

Embodiment 2

[0028] (1) Disperse 1g of graphene in dichloromethane at room temperature, add 2g of polyetheretherketone (PEEK) micropowder after the dispersion is uniform, use a weak base buffer to adjust the pH value of the solution (PH=9), and stir to promote the integration of graphene and Electrostatic adsorption of thermoplastic particles to obtain a stable suspension of self-assembled mixed fillers; (2) Add the above suspension to 18.7g of novolac epoxy resin and stir evenly, then add 1.3g of dicyandiamide curing agent, and vacuum remove the solvent , heating according to the curing system to prepare thermally conductive resin-based composite materials. The thermal conductivity of the composite material was tested, and the thermal conductivity was 1.052w / m.k.

Embodiment 3

[0030] (1) Disperse 0.3g of graphene in ethanol at room temperature, add 1.8g of polyetherimide (PEI) micropowder to it after the dispersion is uniform, use borate buffer to adjust the pH value of the solution (PH=7), and stir Promote the electrostatic adsorption of graphene and thermoplastic particles to obtain a stable suspension of self-assembled mixed fillers; (2) add the above suspension to 16.3g of bisphenol F epoxy resin and stir evenly, then add 3.7g of alicyclic amine curing agent , after removing the solvent in vacuum, heat according to the curing system to prepare a thermally conductive resin-based composite material. The thermal conductivity of the composite material was tested, and the thermal conductivity was 0.451w / m.k.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com