Fabrication method of supercapacitor electrode

A supercapacitor and electrode technology, applied in the manufacture of hybrid capacitor electrodes, electrolytic capacitors, hybrid/electric double layer capacitors, etc. stability, excellent crystallinity and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention provides a method for preparing a supercapacitor electrode. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0028] The supercapacitor electrode preparation method provided in this embodiment specifically includes the following steps:

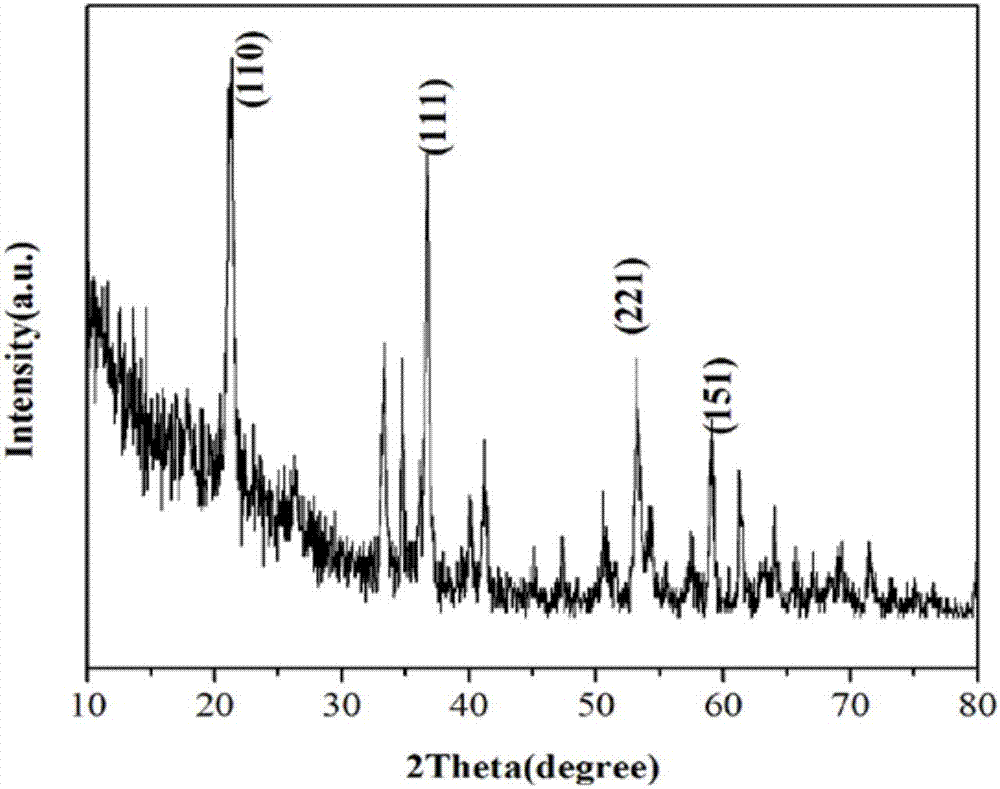

[0029] Hydrothermal synthesis of iron oxide, first 0.01mol Fe(NO 3 ) 3 9H 2 O and 0.04mol KOH were dissolved in 10ml deionized water. Then the KOH solution was added dropwise to the stirring Fe(NO 3 ) 3 9H 2 O solution. Add 20ml of deionized water to the mixed solution, and after stirring for 10 minutes, transfer the mixed solution to a 50ml reaction kettle. The reactor containing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Interplanar spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com