Silicon magnesium-based nano-sized water treatment agent and preparation method thereof

A nano-water and treatment agent technology, applied in water/sewage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as waste of raw materials, loss of adsorbent, deterioration of adsorption performance, etc. The effect of low cost, long service life and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

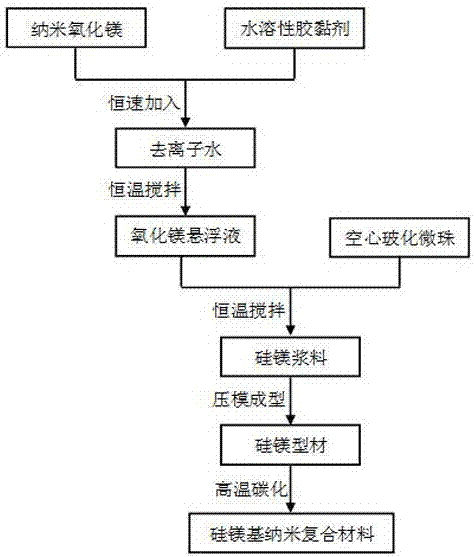

Method used

Image

Examples

Embodiment 1

[0026] Weigh 20g of nano-magnesia powder (particle size 200nm, purity 98.5%), 2.0g of epoxy resin, 3.0g of dioctyl maleate sodium sulfonate, add to 50mL of deionized water, and heat at 50°C 1. Stir at a constant temperature for 60 min at a stirring speed of 500 r / min to form a magnesium oxide suspension. Add 80g of hollow vitrified microspheres (particle size 0.2mm, purity 98.0%) to the above magnesium oxide suspension at a constant speed, and stir at a temperature of 85°C and a stirring speed of 450r / min for 90min to form a silicon-magnesium slurry. The slurry is subjected to mold compression molding and microwave carbonization treatment at a temperature of 450° C. to obtain a cylindrical silicon-magnesium-based nanocomposite material.

[0027] Get this material 1.0g to volume 500mL, the methyl orange removal rate of concentration 60mg / L methyl orange solution at normal temperature after adsorption treatment 30min is 98.2%, to volume 500mL, the Cr(III) salt solution of concen...

Embodiment 2

[0029]Weigh 10g of nano-magnesia powder (particle size 100 nm, purity 98.5%), 1.0g phenolic resin, 1.0g triallyl cyanurate, add to 30mL deionized water, and stir at a temperature of 25°C and a stirring speed of Stir at a constant temperature for 90 min at 1000 r / min to form a magnesium oxide suspension. Add 50g of hollow vitrified microspheres (particle size 0.5mm, purity 98.0%) to the above magnesium oxide suspension at a constant speed, and stir at a temperature of 85°C and a stirring speed of 450r / min for 90min to form a silicon magnesium slurry. The slurry is subjected to mold compression molding and microwave carbonization treatment at a temperature of 350° C. to obtain a cuboid silicon-magnesium-based nanocomposite material.

[0030] Get this material 1.0g to volume 500mL, concentration 35mg / L rhodamine B solution, the methyl orange removal rate 99.0% after adsorption treatment 30min at normal temperature, to volume 500mL, concentration 10mg / L Cr (IV) salt solution at no...

Embodiment 3

[0032] Weigh 50g of nano-magnesia powder (particle size 150 nm, purity 98.5%), add 15.0g of melamine formaldehyde resin to 100mL of deionized water, and stir at a temperature of 80°C and a stirring speed of 100r / min for 30min to form a magnesium oxide suspension liquid. Add 90g of hollow vitrified microspheres (particle size 0.1mm, purity 98.0%) to the above magnesium oxide suspension at a constant speed, and stir at a temperature of 85°C and a stirring speed of 450r / min for 90min to form a silicon-magnesium slurry. The slurry is subjected to mold compression molding and microwave carbonization treatment at a temperature of 350° C. to obtain a spherical silicon-magnesium-based nanocomposite material.

[0033] Get this material 1.0g to the volume 500mL, concentration 20mg / L methylene blue solution, the methyl orange removal rate after adsorption treatment 40min at normal temperature is 99.0%, to the volume 500mL, concentration 10mg / L Cu(II) salt solution adsorption at normal te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com