A kind of Pacific oyster neutral polysaccharide and its preparation method and application

A technology of Pacific oyster and neutral polysaccharide, which is applied in pharmaceutical formulations, allergic diseases, organic active ingredients, etc., can solve the problems of many operation steps, low product yield, reduced activity, etc., and achieves promotion of immune activity and simple extraction process. , the effect of inhibiting proliferation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

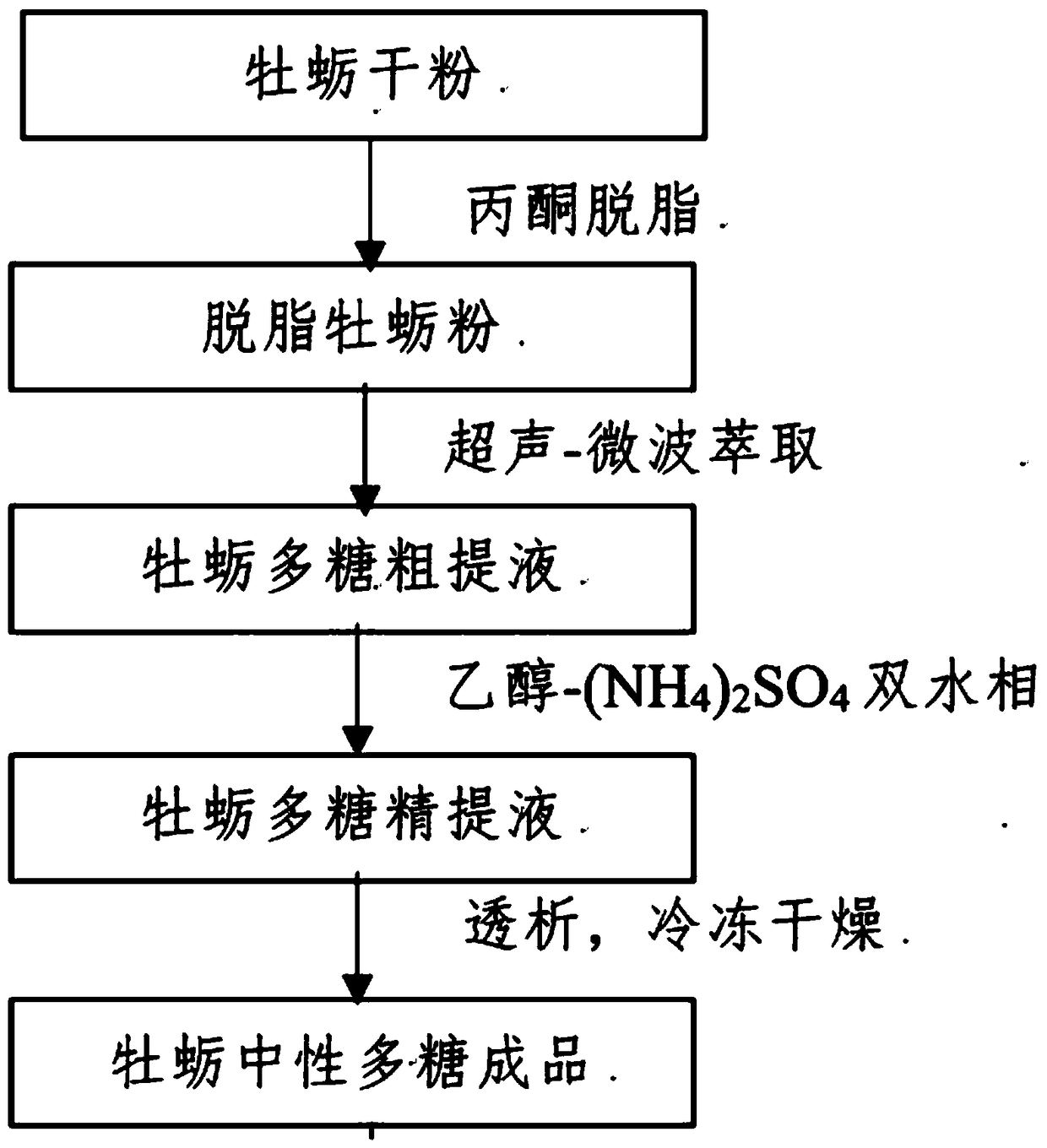

[0038] Embodiment 1: Pacific oyster neutral polysaccharide finished product prepared by the method of the present invention

[0039] Pacific oyster neutral polysaccharide finished product press figure 1 The process shown is prepared, and the specific steps are as follows:

[0040] (1) Preparation of defatted oyster powder: the dried oyster powder was crushed, passed through a 40-mesh sieve, and dried in an oven at 60°C until constant weight. Weigh 6g of oyster powder and add it to 60ml of deionized water, add 3 times the volume of acetone to wash, centrifuge at 6000rpm at 4°C for 20min, and dry at low temperature to obtain defatted oyster powder.

[0041] (2) Preparation of oyster polysaccharide crude extract: put the defatted oyster powder obtained in step (1) into a 1000mL glass extraction container, add 600mL deionized water and place it in a 500W ultrasonic microwave extractor for processing at a temperature of 86°C. Time 26min, cooling after extraction. The extract was...

Embodiment 2

[0058] Embodiment 2: HPLC detects the molecular weight and the purity of the Pacific oyster neutral polysaccharide prepared by the method of the present invention

[0059] Conditions: separation column: TSKgel G4000SW (300mm×7.5mm); mobile phase: ammonium acetate solution (0.05mol / L); sample concentration: detailed data later; injection volume: 20μL; flow rate: 0.5mL / min, drift tube temperature : 55°C, carrier gas flow rate: 2L / min, impactor: on. The result is shown in 6, which is a symmetrical peak type with a narrow peak width.

Embodiment 3

[0060] Example 3: Detection of monosaccharide composition determination in Pacific oyster neutral polysaccharide prepared by the method of the present invention (1) Weigh 10 mg of Pacific oyster neutral polysaccharide prepared by the method of the present invention, place it in a 10 mL graduated test tube with stopper, add 1 mol / L of H 2 SO 4 2mL, sealed. Hydrolyze at a constant temperature of 100°C for 4 hours, and after cooling the hydrolyzate, wash with saturated Ba(OH) 2 Neutralize to neutral, centrifuge at 3000rpm for 10min to remove BaSO 4 precipitation. Transfer all the supernatant to a 10mL measuring bottle, dilute to the mark with distilled water, and filter the solution through a 0.45 μm microporous membrane to obtain oyster neutral polysaccharide hydrolyzate.

[0061] (2) HPLC-ELSD instrument detection: glucose standard (500μg / mL), oyster neutral polysaccharide hydrolyzate, chromatographic column Carbohydrate ES 5u (250mm×4.6mm); mobile phase: acetonitrile-wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com