A kind of preparation method of superhydrophobic film on the surface of metal material

A metal material and super-hydrophobic technology, applied in the field of metal surface treatment, can solve the problems of super-hydrophobic research process complexity, insufficient research, high cost of raw materials, etc., achieve good hydrophobic effect, improve strength and hydrophobicity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

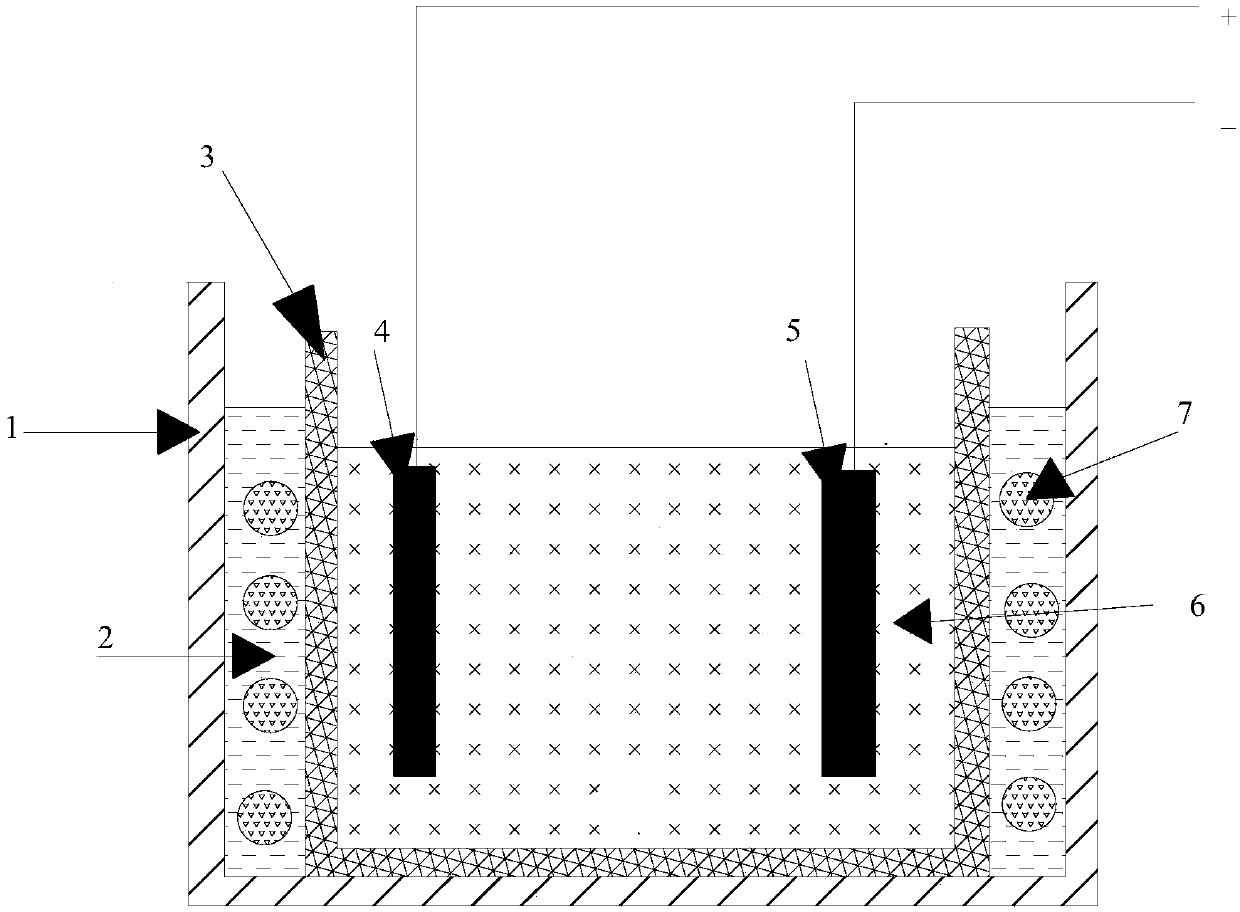

[0058] A method for preparing super-hydrophobic film on the surface of metal materials, see the schematic diagram of the process flow Figure 5 , Specifically including the following steps:

[0059] Step 1, substrate pretreatment

[0060] Take Cr5 steel plate with hardness HV=800 as the metal matrix, soak the Cr5 steel plate in 60℃ lye for 3 minutes, rinse with deionized water after taking it out, soak it in pickling solution for 30s, after taking it out, use deionized water Rinse to remove oil stains and oxides on the surface of the Cr5 steel plate to obtain a Cr5 steel plate after impurity removal;

[0061] Among them, the components contained in the lye and its mass concentration are Na 2 CO 3 :10g / L, NaOH: 25g / L, Na 4 P 2 O 7 ·10H 2 O: 90g / L, emulsifier OP-10: 2g / L;

[0062] Pickling liquid is dilute H 2 SO 4 The solution has a molar concentration of 0.4mol / L.

[0063] Step 2, electroplating

[0064] Take the Cr5 steel plate after impurity removal as the cathode, Ti-IrO 2 The materi...

Embodiment 2

[0075] A method for preparing a super-hydrophobic film on the surface of a metal material specifically includes the following steps:

[0076] Step 1, substrate pretreatment

[0077] Take the Cr5 steel plate with hardness HV=800 as the metal matrix, soak the Cr5 steel plate in 65℃ lye for 5 minutes, rinse with deionized water after taking it out, soak it in pickling solution for 30s, after taking it out, use deionized water Rinse to remove oil stains and oxides on the surface of the Cr5 steel plate to obtain a Cr5 steel plate after impurity removal;

[0078] Among them, the components contained in the lye and its mass concentration are Na 2 CO 3 :15g / L, NaOH: 30g / L, Na 4 P 2 O 7 ·10H 2 O: 95g / L, emulsifier OP-10: 3g / L;

[0079] Pickling liquid is dilute H 2 SO 4 The solution has a molar concentration of 0.5mol / L.

[0080] Step 2, electroplating

[0081] The Cr5 steel plate after impurity removal is used as the cathode, the insoluble lead-tin alloy is used as the anode, the electrode spac...

Embodiment 3

[0088] A method for preparing a super-hydrophobic film on the surface of a metal material specifically includes the following steps:

[0089] Step 1, substrate pretreatment

[0090] Using T2 copper plate as the metal substrate, soak the T2 copper plate in 70℃ lye for 3 minutes, take it out and rinse with deionized water, soak it in pickling solution for 30s, after taking it out, rinse with deionized water to remove the T2 copper plate Oil stains and oxides on the surface to obtain a T2 copper plate after impurity removal;

[0091] Among them, the components contained in the lye and its mass concentration are Na 2 CO 3 :10g / L, NaOH: 25g / L, Na 4 P 2 O 7 ·10H 2 O: 90g / L, emulsifier OP-10: 2g / L;

[0092] Pickling liquid is dilute H 2 SO 4 The solution has a molar concentration of 0.4mol / L.

[0093] Step 2, electroplating

[0094] Take the T2 copper plate after cleaning as the cathode, Ti-IrO 2 The material is used as the anode, the electrode spacing is 0.5cm, it is placed in the electroplat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com