Achievement method for roof system structure

An implementation method and technology of a roofing system, which are applied in the direction of roofing, roof covering, roof decoration, etc., can solve the problems of large amount of work, many construction steps, and speed up the aging degree of thermal insulation materials, so as to improve and reduce the time cost and economic cost. Material waste and labor loss, the effect of reducing the use of non-renewable resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

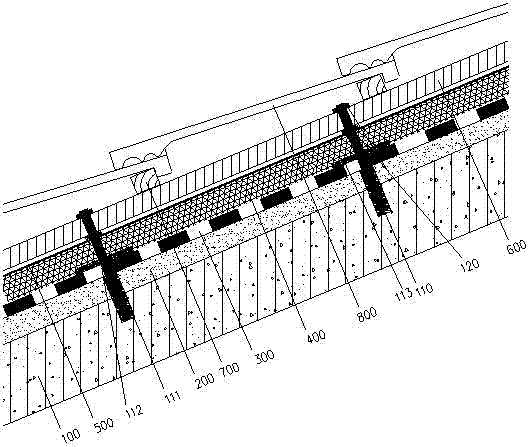

[0044] The realization method of roof system structure of the present invention, it comprises the steps:

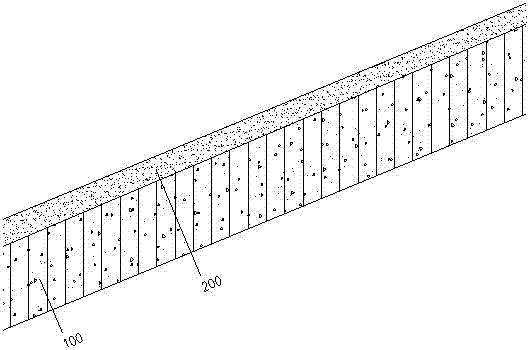

[0045] Step 1, laying a cement mortar leveling layer 200 on the reinforced concrete base 100;

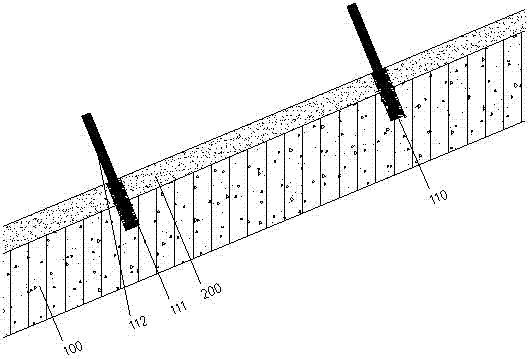

[0046] Step 2: On the reinforced concrete base 100 and the cement mortar screed layer 200, use an electric hammer to punch holes for the reinforcement used. The hole diameter must be greater than the diameter of the reinforcement bolt 110 to be planted, and the depth must not be less than 50-80mm (the depth is mainly Depends on the length of the exposed part of the planting bolts and the slope of the roof), after the drilling is completed, clean the dust;

[0047] Step 3: First, drive the reinforcement glue 111 into the reinforcement hole, then rotate the reinforcement bolts 110 in the same direction and insert them into the reinforcement glue 111, and wait until the reinforcement bolts 110 are inserted into the bottom of the hole, and the reinforcement glue overflows. After t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Horizontal spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com