Graphene/tin dioxide quantum dot composite material-based NO2 sensor and preparation method thereof

A technology of tin dioxide and composite materials, which is applied in the analysis of materials, material resistance, material analysis by electromagnetic means, etc. It can solve the problems of short response recovery time and low detection limit, and achieve fast response recovery speed and low working temperature. , the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

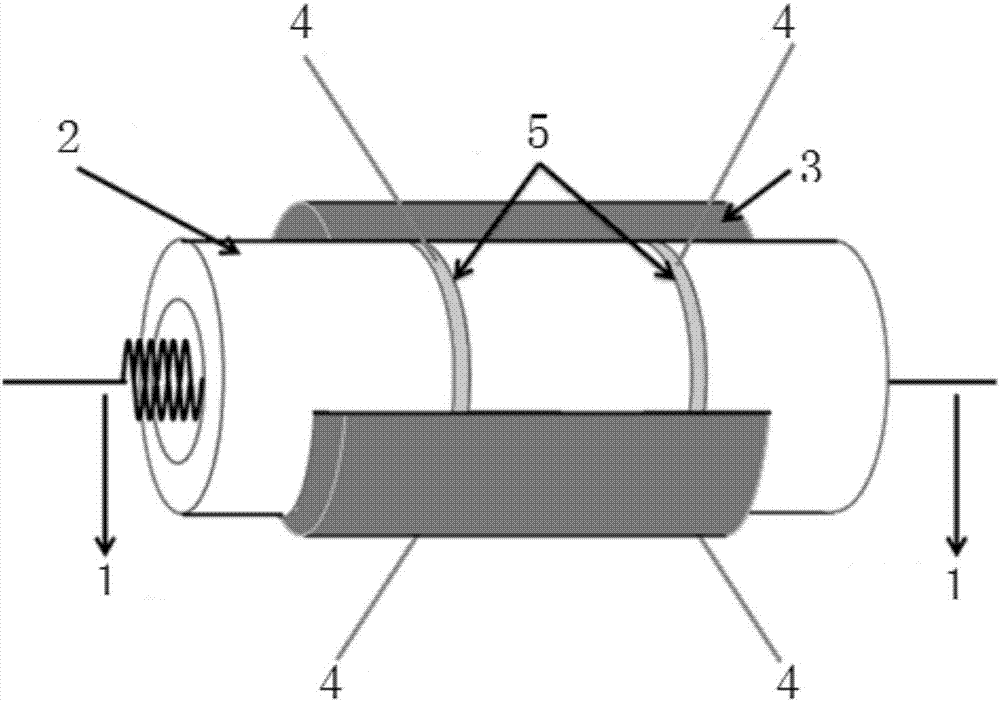

Embodiment 1

[0031] (1) get the graphene / tin dioxide quantum dot composite material 0.2g that Graphene mass fraction is about 2% and 2g ethanol uniformly mix and form slurry; This slurry is evenly coated on the surface with a pair of testing gold electrodes Al 2 o 3 on the surface of the ceramic tube so that it completely covers the gold electrodes. Among them, the thickness of the graphene / tin dioxide quantum dot composite material is 15-30um; Al 2 o 3 The inner diameter of the ceramic tube is 0.8mm, the outer diameter is 1.2mm, and the length is 5mm; the width of a single gold electrode is 0.5mm, and the distance between two gold electrodes is 0.5mm; the length of the platinum wire drawn from the gold electrode is 5mm .

[0032] (2) Dry the ceramic tube coated with the graphene / tin dioxide quantum dot sensitive material at room temperature, and then transfer it to an oven at 80° C. to continue drying for 30 minutes. Next thread the NiCd alloy heating coil into the Al 2 o 3 The cer...

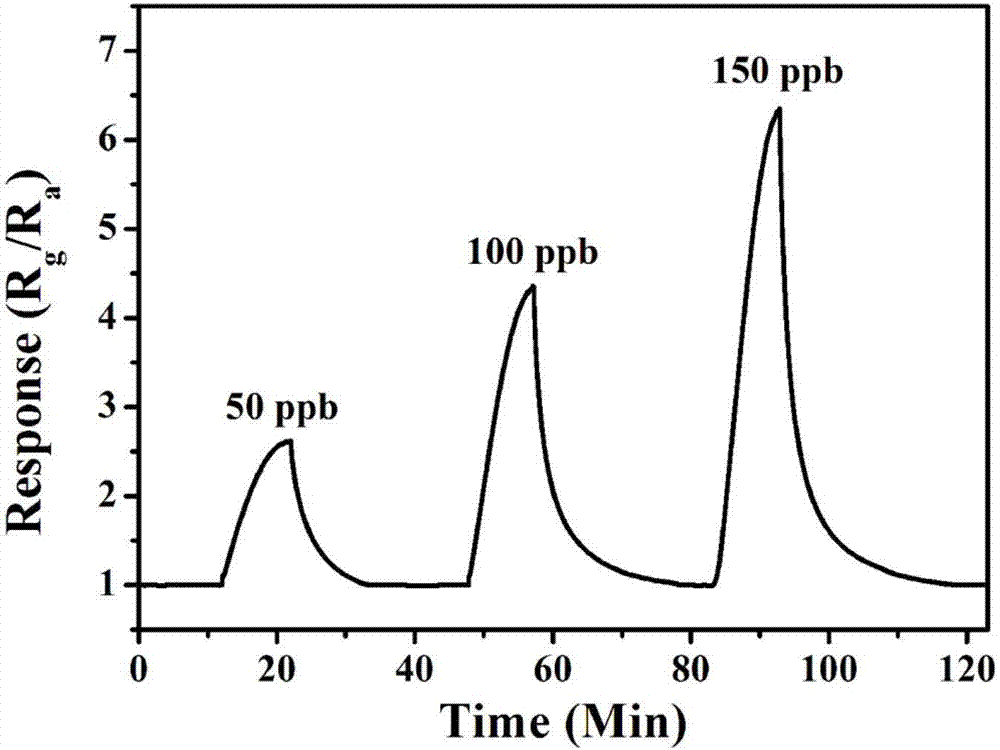

Embodiment 2

[0036] (1) get the graphene / tin dioxide quantum dot composite material 0.2g that Graphene mass fraction is about 2% and 2g ethanol uniformly mix and form slurry; This slurry is evenly coated on the surface with a pair of testing gold electrodes Al 2 o 3 on the surface of the ceramic tube so that it completely covers the gold electrodes. Among them, the thickness of the graphene / tin dioxide quantum dot composite material is 15-30um; Al 2 o 3 The inner diameter of the ceramic tube is 0.8mm, the outer diameter is 1.2mm, and the length is 5mm; the width of a single gold electrode is 0.5mm, and the distance between two gold electrodes is 0.5mm; the length of the platinum wire drawn from the gold electrode is 5mm .

[0037] (2) Dry the ceramic tube coated with the graphene / tin dioxide quantum dot sensitive material at room temperature, and then transfer it to an oven at 80° C. to continue drying for 30 minutes. Next thread the NiCd alloy heating coil into the Al 2 o 3 The cer...

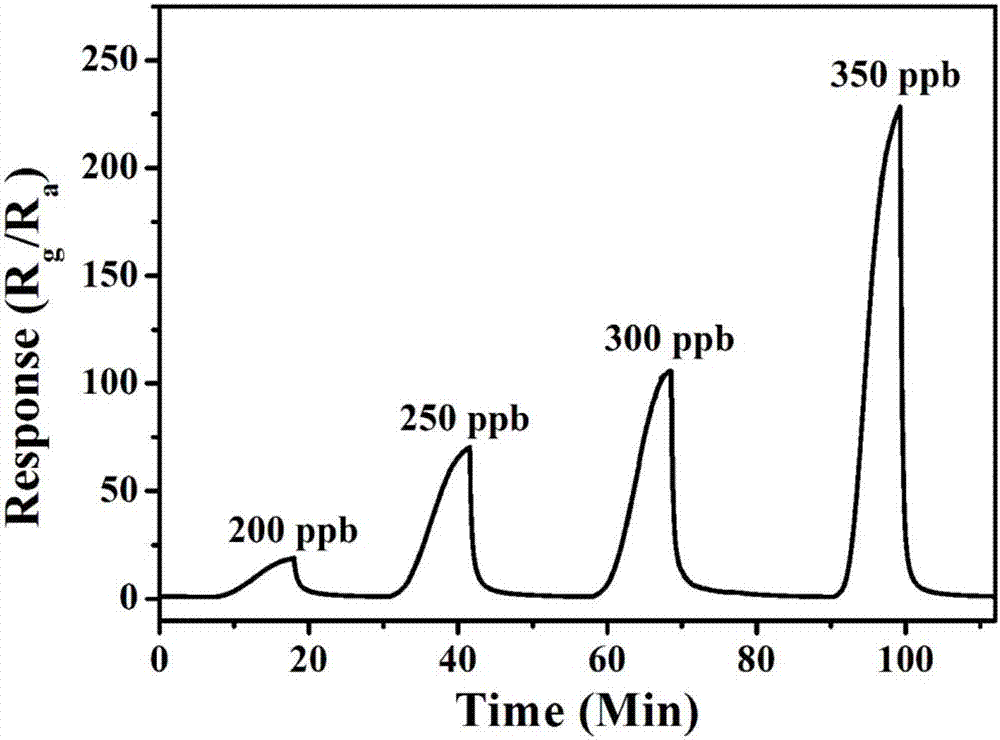

Embodiment 3

[0041] (1) get the graphene / tin dioxide quantum dot composite material 0.2g that Graphene mass fraction is about 2% and 2g ethanol uniformly mix and form slurry; This slurry is evenly coated on the surface with a pair of testing gold electrodes Al 2 o 3 on the surface of the ceramic tube so that it completely covers the gold electrodes. Among them, the thickness of the graphene / tin dioxide quantum dot composite material is 15-30um; Al 2 o 3 The inner diameter of the ceramic tube is 0.8mm, the outer diameter is 1.2mm, and the length is 5mm; the width of a single gold electrode is 0.5mm, and the distance between two gold electrodes is 0.5mm; the length of the platinum wire drawn from the gold electrode is 5mm .

[0042] (2) Dry the ceramic tube coated with the graphene / tin dioxide quantum dot sensitive material at room temperature, and then transfer it to an oven at 80° C. to continue drying for 30 minutes. Next thread the NiCd alloy heating coil into the Al 2 o 3 The cer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com