A kind of preparation method of chalcogenide glass photonic crystal optical fiber preform rod

A technology of photonic crystal fiber and chalcogenide glass, applied in glass manufacturing equipment, glass production, manufacturing tools, etc., can solve the problems of hollow hole surface defects, restraint, and low success rate, so as to avoid voids and defects and improve processing efficiency , The effect of reducing fiber loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

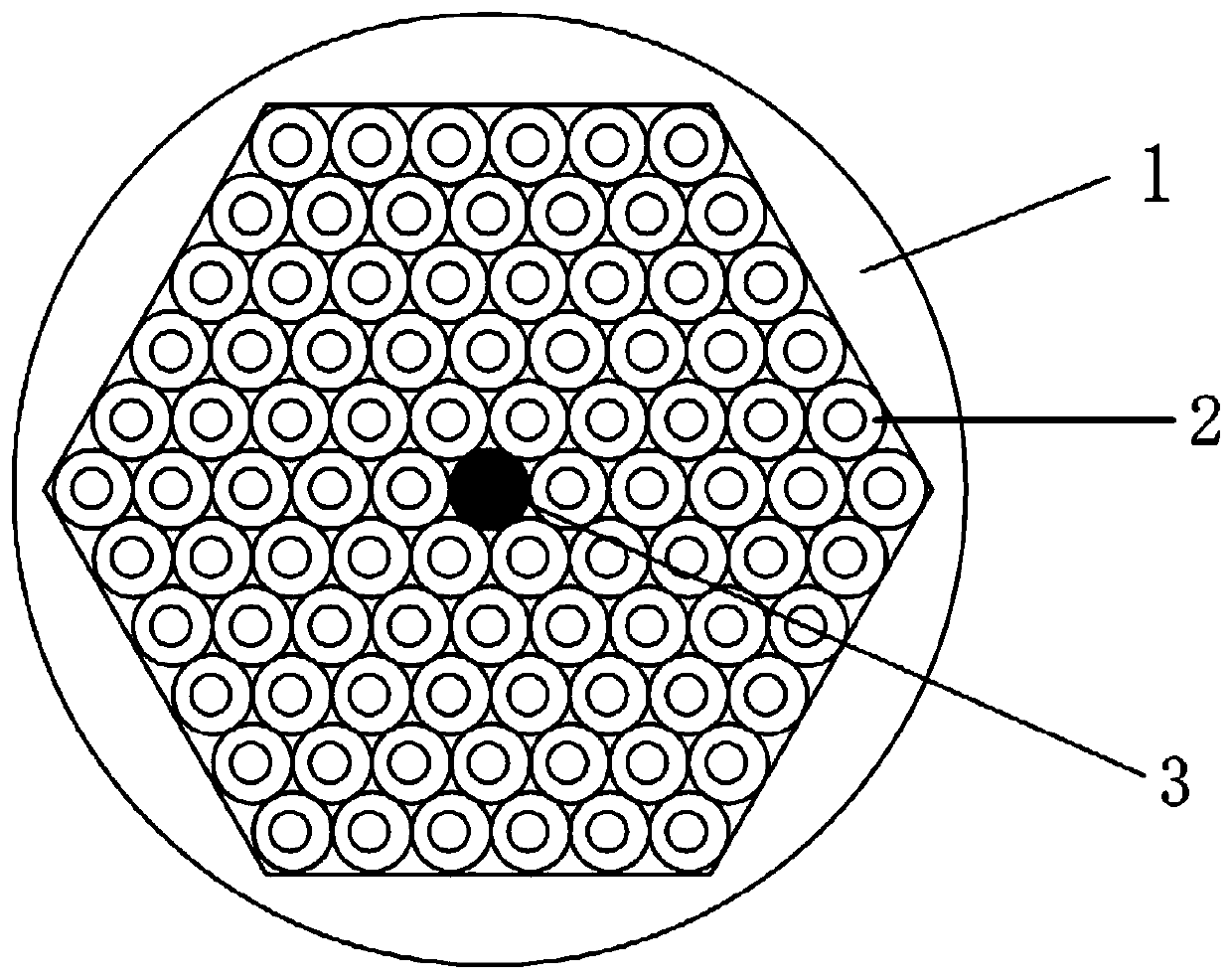

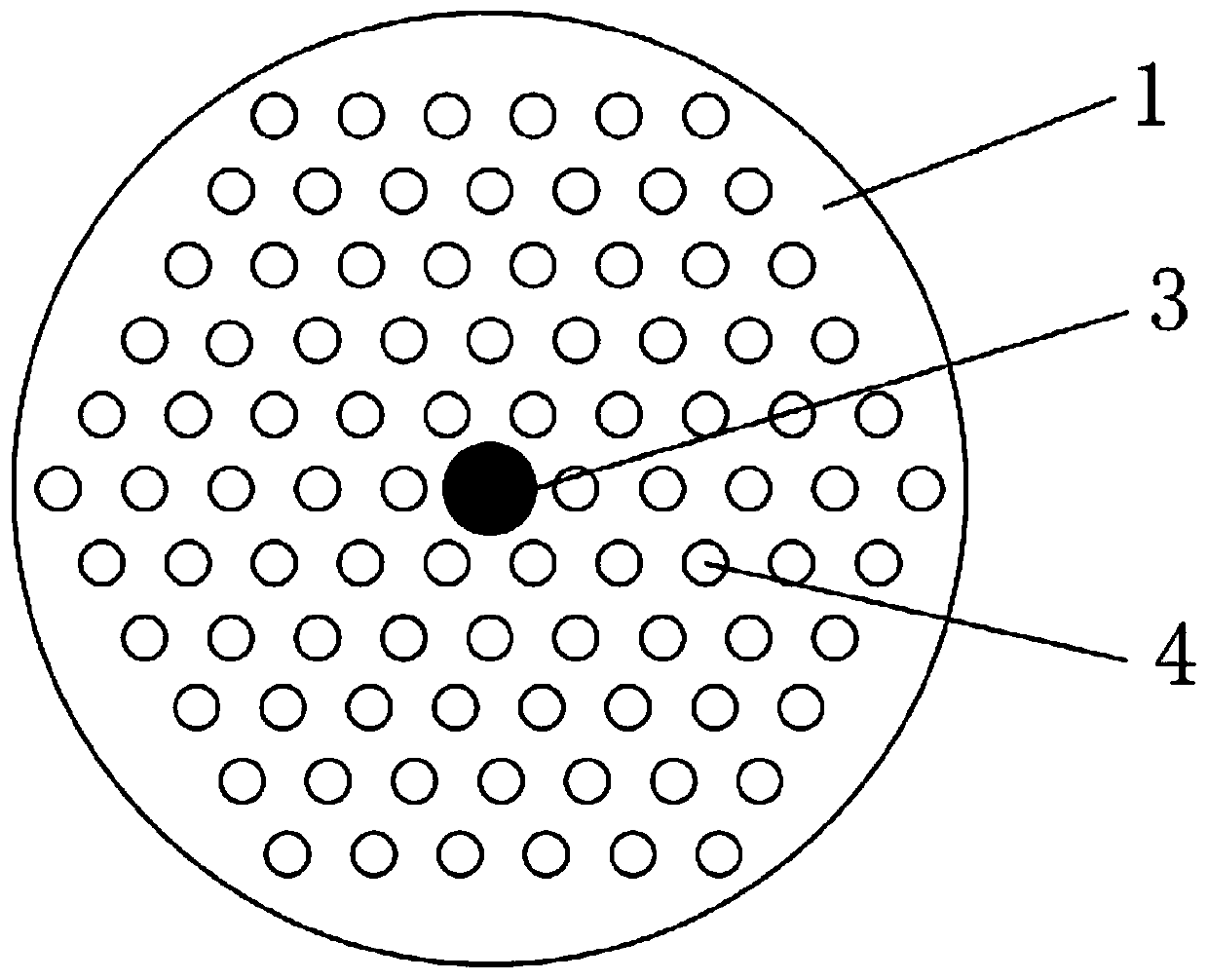

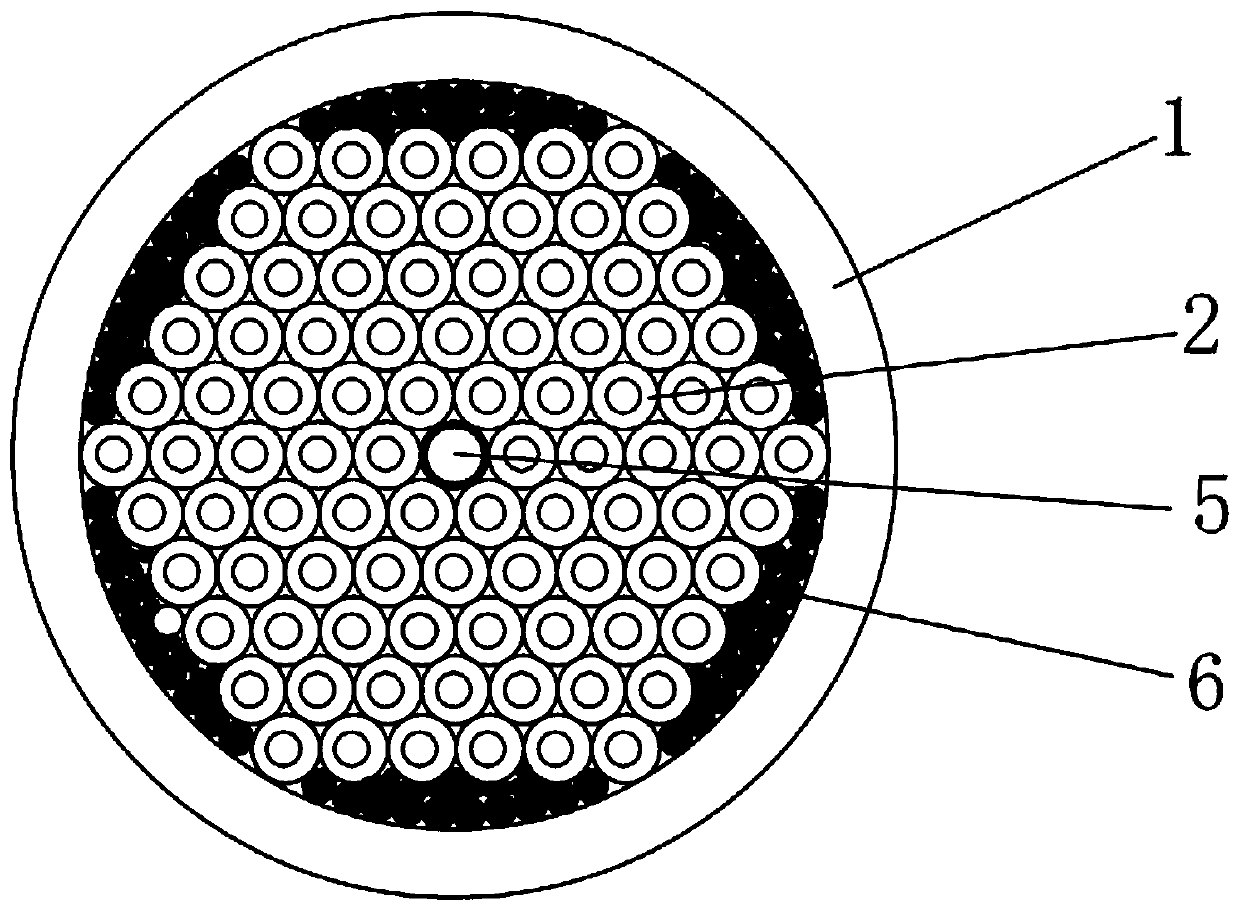

[0025] To prepare chalcogenide glass photonic crystal optical fiber, the traditional melt cooling method is used to prepare chalcogenide glass materials. The sample preparation is through pretreatment of quartz ampoules, weighing of starting materials, vacuum sealing, melting, annealing, cutting, drilling hole and other processes to obtain the glass empty tube and the outer tube 1 of the corresponding duty cycle. Drawing is performed on the obtained chalcogenide glass empty tube, and the drawn optical fiber is required to have a uniform size, and the capillary 2 with a uniform size corresponding to the duty ratio is prepared by drawing.

[0026] Use an optical fiber cutter to cut off a capillary 2 with a moderate length, put the capillary 2 into a vacuum heating furnace, and then go through the initial slow vacuuming and the later molecular pump vacuuming to reach 1×10 -6 Pa pressure, while heating the capillary 2 to the glass transition temperature T g +20°C, keep warm for 2...

Embodiment 2

[0032] To prepare chalcogenide glass photonic crystal optical fiber, the traditional melt cooling method is used to prepare chalcogenide glass materials. The sample preparation is through pretreatment of quartz ampoules, weighing of starting materials, vacuum sealing, melting, annealing, cutting, drilling hole and other processes to obtain the glass empty tube and the outer tube 1 of the corresponding duty cycle. Drawing is performed on the obtained chalcogenide glass empty tube, and the drawn optical fiber is required to have a uniform size, and the capillary 2 with a uniform size corresponding to the duty ratio is prepared by drawing.

[0033] Use an optical fiber cutter to cut off a capillary 2 with a moderate length, put the capillary 2 into a vacuum heating furnace, and then go through the initial slow vacuuming and the later molecular pump vacuuming to reach 1×10 -6 Pa pressure, while heating the capillary 2 to the glass transition temperature T g -20°C, keep warm for 2...

Embodiment 3

[0038] With above-mentioned specific embodiment 1, its difference is:

[0039] The capillary is heated to the glass transition temperature T g °C; heat the chalcogenide glass photonic crystal primary preform to the glass transition temperature T g +110°C, keep warm and set for 1h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com