High-heat-resistance low-light-transmittance acrylonitrile-butadiene-styrene composition and preparation method thereof

A technology of acrylonitrile and butadiene, which is applied in the field of acrylonitrile-butadiene-styrene composition and its preparation, can solve the problem of reducing light transmittance, light diffusing agent and light blocking agent without clear selection target and no effective Improve the dispersion effect of light diffusing agent and light blocking agent, and do not completely solve the problems of ABS resin condition range, etc., achieve excellent shading effect, good dispersion effect, and improve the success rate of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

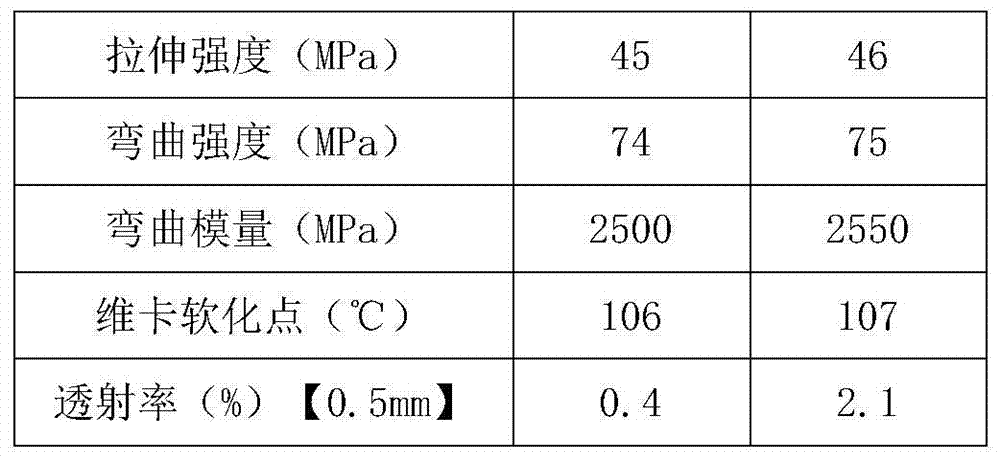

Embodiment 1

[0050] 55 parts of Daqing 750, 12 parts of 80HF, 10 parts of HR-15, 15 parts of superfine barium sulfate and fine calcium carbonate mixture (the weight ratio of the two = 2:1), 7 parts of R-760, 0.5 parts of light stabilizer ( 0.3 parts of LA-944, 0.2 parts of UV-360), 0.5 parts of processing aids (0.3 parts of heat stabilizer, 0.2 parts of lubricant) are mixed evenly by high-speed stirring, and the above mixture is sent into the internal mixer machine, and the Under the action of stirring and shearing, it is fully melted and mixed, and then pressed into 2 mm thin slices by a film laminator, and then cut into pellets with a cutter.

[0051] The temperature of the internal mixer is 220° C., and the rotational speed of the rotor of the internal mixer is 70 rpm.

[0052] The prepared material was injection molded into a standard sample bar for testing according to the standard size, and the performance test results are shown in Table 2.

Embodiment 2

[0058] With 64 parts of Daqing 750, 10 parts of HR-15, 13 parts of ultrafine barium sulfate, 12 parts of R-760, 0.5 part of light stabilizer (0.3 part of LA-944, 0.2 part of UV-360), 0.5 part of processing aid ( 0.3 parts of heat stabilizer, 0.2 parts of lubricant) are mixed evenly by high-speed stirring, and the above-mentioned mixture is sent into the internal mixer, fully melted and mixed under the stirring and shearing action of the rotor, and then pressed into 2 mm flakes, and then cut into pellets with a cutter.

[0059] The temperature of the internal mixer is 180° C., and the rotational speed of the rotor of the internal mixer is 70 rpm.

[0060] The prepared material was injection molded into a standard sample bar for testing according to the standard size, and the performance test results are shown in Table 3.

Embodiment 3

[0066] 74 parts of Daqing 750, 10 parts of 80HF, 20 parts of HR-15, 3 parts of ultra-fine barium sulfate, 2 parts of R-760, 0.5 parts of light stabilizer (0.3 parts of LA-944, 0.2 parts of UV-360), processing aids 0.5 parts of agent (0.3 parts of heat stabilizer, 0.2 parts of lubricant) are mixed evenly by high-speed stirring, and the above mixture is sent into the internal mixer, fully melted and mixed under the stirring and shearing action of the rotor, and then pressed into the film Machine pressed into 2 mm thin slices, and then cut into pellets with a cutter.

[0067] The temperature of the internal mixer is 250° C., and the rotational speed of the rotor of the internal mixer is 70 rpm.

[0068] The prepared material was injection molded into a standard sample bar for testing according to the standard size, and the performance test results are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com