Method for synthesizing monoglyceride in ionic liquid system by enzymic method

An ionic liquid and enzymatic synthesis technology, applied in fermentation and other fields, can solve the problems of low reaction selectivity, environmental pollution, and many side reactions, and achieve the effects of increasing contact area, wide liquid range, and improving mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

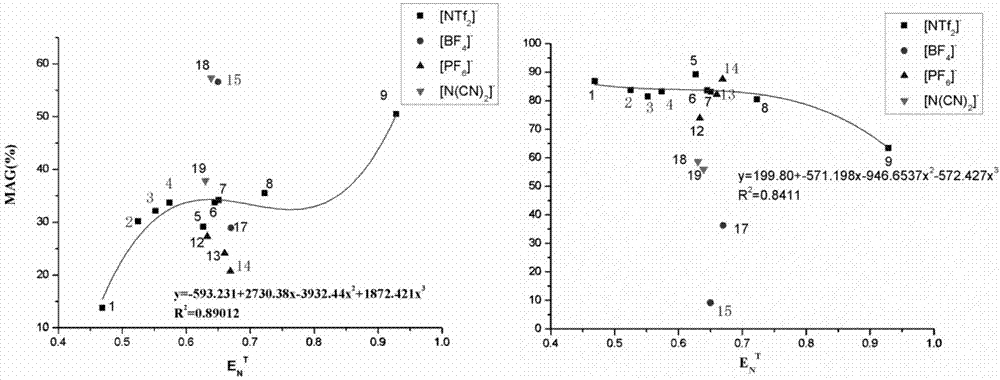

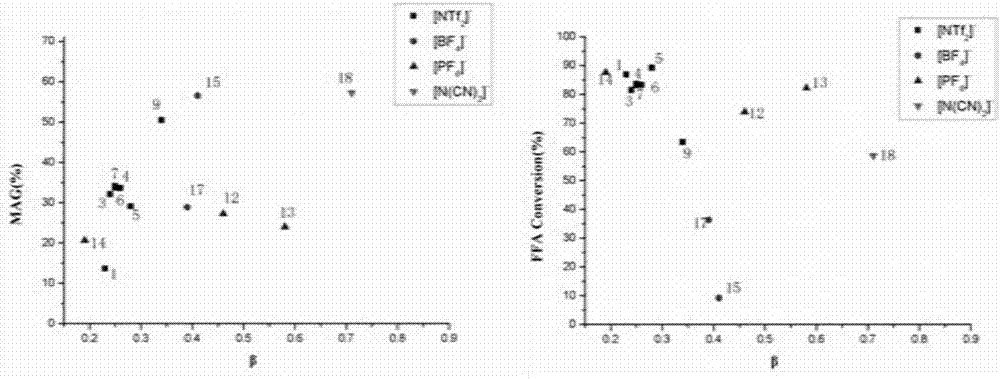

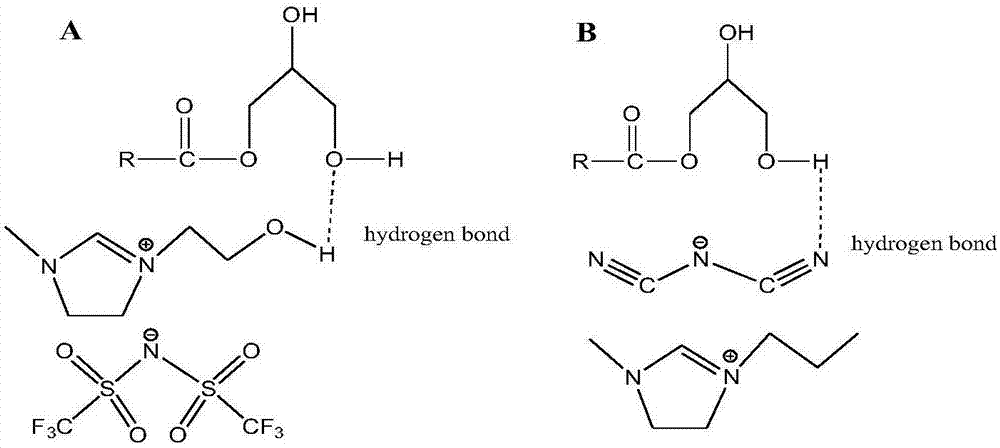

[0029] 1.1 Screening of ionic liquids

[0030] Mix 1.049g oleic acid (5mmol) and 0.460g glycerin (5mmol), add ionic liquid (0.5608g) accounting for 30% of the total mass of the substrate as a reaction medium, and after stirring, add 4% of the total mass of the substrate. For lipase Novozyme435, react at a temperature of 60° C. for 8 hours with magnetic stirring, and then centrifuge to remove the ionic liquid (including glycerol) and lipase to obtain a product containing monoglyceride. The content of MAG in the reaction system was detected by normal phase high performance liquid chromatography with evaporative light detector (NP-HPLC-ELSD) and quantified by external standard method, and the change of fatty acid content was detected by acid-base titration. Esterification rate=(1-molar weight of fatty acid after reaction / molar weight of fatty acid before reaction)×100%

[0031] Analysis of MAG content by NP-HPLC-ELSD

[0032] Take out 20ul reaction mixture each time at a certai...

Embodiment 2

[0057] Add lauric acid and glycerol to the reactor with a molar ratio of 1:1, add 30% ionic liquid [HO(CH 2 ) 2 MIM]NTf 2 , put in a stirrer, preheat in a constant temperature water bath with a temperature of 60°C, turn on the magnetic stirrer, stir at a speed of 450rpm, add lipase Novozyme435 accounting for 4% of the total mass of the substrate, 4% 4A molecular sieve, and start After reacting for 8 hours, the product was taken out, and the ionic liquid and lipase were removed by centrifugation at 10,000 rpm for 10 minutes. According to liquid phase analysis, the content of monoglyceride in the product was 52.5%.

Embodiment 3

[0059] Caprylic acid and glycerin are added in the reactor with the molar ratio of 1:1, add the ionic liquid [MeO(CH 2 ) 2 MIM]NTf 2 , put in a stirrer, preheat in a constant temperature water bath with a temperature of 60°C, turn on the magnetic stirrer, stir at a speed of 450rpm, add lipase Novozyme435 accounting for 4% of the total mass of the substrate, 4% 4A molecular sieve, and start After reacting for 8 hours, the product was taken out, and the ionic liquid and lipase were removed by centrifugation at 10,000 rpm for 10 minutes. According to liquid phase analysis, the content of monoglyceride in the product was 51.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com